Content last revised on November 20, 2025

Lumineq EL512.256-H3: Uncompromising Clarity in Extreme Operating Conditions

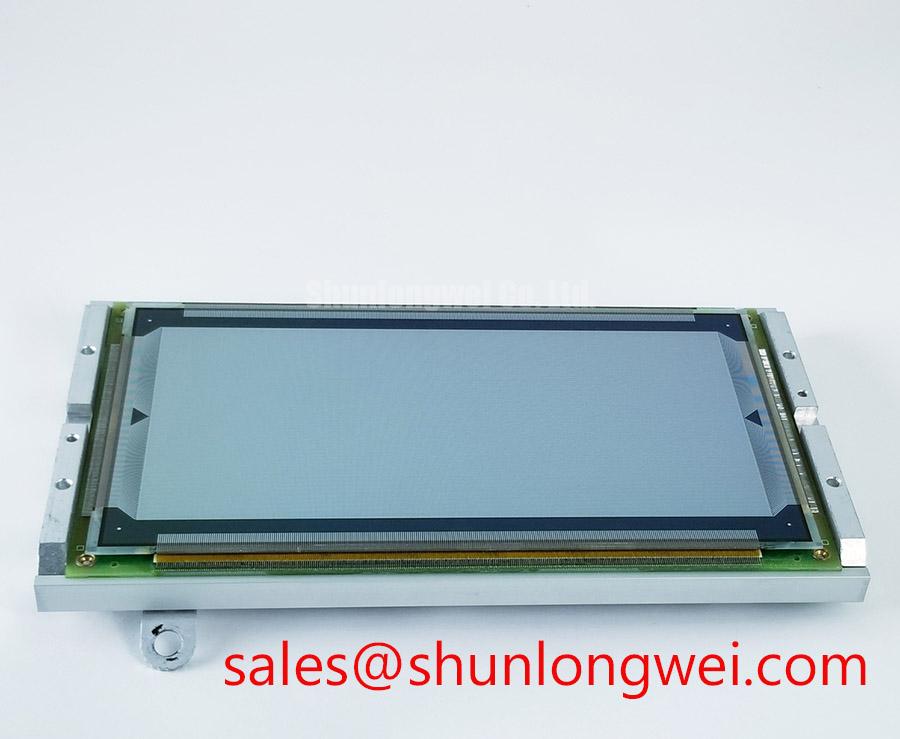

Engineered for mission-critical applications where failure is not an option, the Lumineq EL512.256-H3 is a Thin Film Electroluminescent (TFEL) display delivering unparalleled visual performance and ruggedness. With a crisp 512x256 resolution and an operational temperature range of -25 to +65°C, this 8.6-inch panel provides instant-on performance and stable brightness under conditions where conventional displays falter. Its core advantages include exceptional shock and vibration resistance and a sub-1ms response time. This display directly addresses the need for a supremely durable human-machine interface (HMI) solution in environments subject to severe mechanical stress and temperature extremes. For systems demanding unwavering readability in harsh industrial, military, or transportation environments, the EL512.256-H3's intrinsic durability makes it the definitive choice.

Application Scenarios & Value

System-Level Benefits in High-Vibration and Temperature-Variant Environments

The EL512.256-H3 excels in applications where standard liquid crystal displays compromise reliability. A key engineering challenge in mobile heavy machinery or avionics is ensuring display legibility during high-G events and across wide temperature shifts. The EL512.256-H3's solid-state TFEL technology provides a direct solution. Its ability to withstand a 100 G-force, 6 ms shock (per IEC 60068-2-27) is not just a specification; it's an enabler of continuous operation in environments like military ground vehicles or drilling control panels where shock and vibration are constants. Unlike LCDs that require heaters in the cold or suffer from degraded performance in heat, this display maintains consistent brightness and a response time of less than 1 ms across its entire temperature range. This eliminates the need for auxiliary thermal management systems, simplifying the overall design and reducing potential points of failure. The result is a lower total cost of ownership and enhanced system reliability for the end-user.

For applications requiring a different form factor or resolution, models such as the KCG057QV1DB-G000 may provide alternative solutions within a broader system architecture.

Key Parameter Overview

Decoding the Specs for Extreme Environment Viability

The technical specifications of the Lumineq EL512.256-H3 underscore its suitability for the most demanding applications. The following parameters are critical for design engineers to consider.

| Parameter | Value | Engineering Implication |

|---|---|---|

| Technology | Thin Film Electroluminescence (TFEL) | Provides inherent ruggedness, wide viewing angles, and rapid response times. |

| Resolution | 512 x 256 pixels | Delivers clear, sharp images for detailed data and graphical interfaces. |

| Operating Temperature | -25°C to +65°C | Ensures reliable, instant-on performance without heaters or fans. |

| Storage Temperature | -40°C to +75°C | Offers resilience during transport and storage in non-controlled environments. |

| Response Time | < 1 ms | Eliminates motion blur, crucial for real-time data monitoring and control. |

| Viewing Angle | > 179° | Guarantees excellent readability from virtually any operator position. |

| Shock Resistance | 100 g-force, 6 ms (IEC 60068-2-27) | Confirms survivability and operational integrity in high-impact environments. |

| Luminance | 65 cd/m² (Typical Areal) | Offers crisp, high-contrast visibility suitable for varied lighting conditions. |

Download the EL512.256-H3 datasheet for detailed specifications and performance curves.

Technical Deep Dive

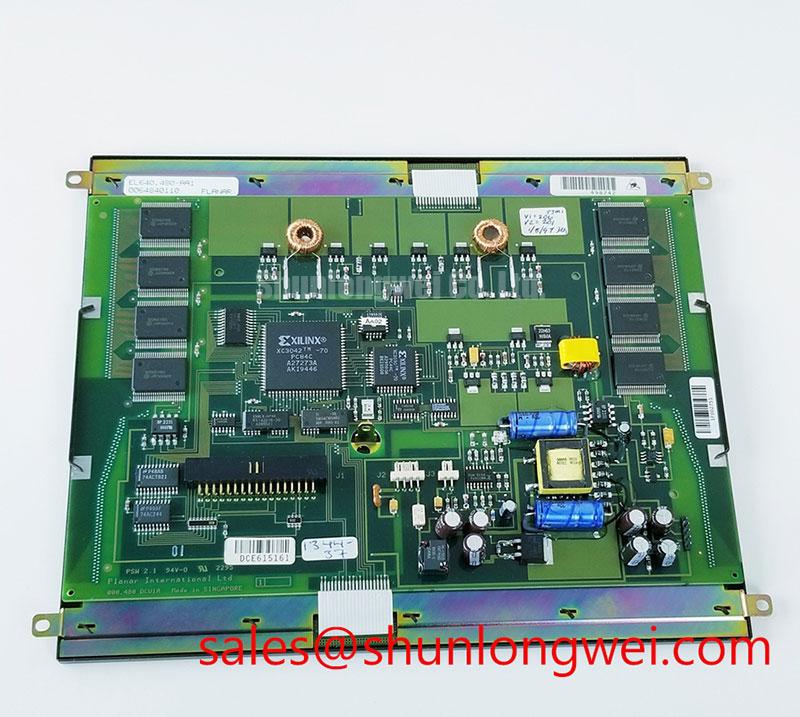

A Closer Look at TFEL's Inherent Ruggedness

The exceptional durability of the Lumineq EL512.256-H3 is rooted in its Thin Film Electroluminescent (TFEL) construction. Unlike the complex liquid and polarizer layers of an LCD, a TFEL panel is a solid-state device. Imagine it as a microscopic sandwich: a thin film of luminescent material is deposited between transparent dielectric layers and a matrix of electrodes, all on a single glass substrate. This monolithic structure is inherently robust. What is the primary benefit of its solid-state design? It eliminates the failure points common in liquid-based displays, such as freezing, boiling, or susceptibility to pressure, making it ideal for avionics displays and other critical applications. Furthermore, the absence of a backlight simplifies the design and contributes to an impressive MTBF of over 30,000 hours, ensuring long-term operational reliability with minimal maintenance. This construction is the engineering foundation for the display's performance in extreme environments.

FAQ

How does the