EL6648MSS | Rugged 6.6" TFEL Display for Extreme Environments

The Lumineq EL6648MSS is a Thin Film Electroluminescent (TFEL) display engineered for absolute reliability and optical clarity in the most mechanically and thermally demanding environments. It delivers mission-critical data with a 640x480 VGA resolution across an extreme -50°C to +85°C operating temperature range, backed by a 200 g shock resistance capability. This display provides unfailing performance where conventional screens fail, ensuring superior long-term reliability. It directly addresses the need for a rugged VGA display that remains fully operational in temperature extremes without performance degradation. For embedded HMI systems in defense or heavy industry requiring fail-safe readability, the EL6648MSS's TFEL technology is the definitive choice.

Key Parameter Overview

Decoding the Specifications for Extreme Environment Viability

The technical specifications of the EL6648MSS are a direct reflection of its design for harsh-duty applications. Each parameter underscores its suitability for environments where standard displays are not a viable option. The combination of a wide temperature tolerance and exceptional mechanical durability provides a robust foundation for building highly reliable systems.

| Parameter | Value |

|---|---|

| Display Technology | Thin Film Electroluminescent (TFEL) |

| Resolution | 640 x 480 (VGA) |

| Diagonal Size | 6.6 inches |

| Operating Temperature | -50°C to +85°C |

| Shock Resistance | 200 g (glass) |

| Viewing Angle | > 179° (Horizontal & Vertical) |

| Response Time | < 1 ms |

| MTBF (Mean Time Between Failures) | > 100,000 hours |

| Interface | 4-bit LCD (LVCMOS) |

Application Scenarios & Value

System-Level Benefits in Mission-Critical HMI Design

The EL6648MSS is engineered for applications where display failure is not an option. Its core value lies in delivering consistent performance regardless of external conditions, which simplifies system design and enhances overall reliability. What is the core benefit of TFEL technology? Intrinsic immunity to extreme temperatures and mechanical shock.

A prime engineering scenario is the operator Human-Machine Interface (HMI) in heavy-duty mining or forestry equipment. Operators face the challenge of needing instant, legible data in environments that swing from deep-freeze conditions to high-heat, all while subjected to constant, severe vibration. A conventional LCD would suffer from slow response times or complete failure at low temperatures. The EL6648MSS, with its < 1 ms response time and -50°C operational floor, solves this problem directly. This ensures critical machine data is always available, improving both safety and operational efficiency in industrial automation contexts. Its use as a COTS component with military-grade resilience allows for rapid deployment in ruggedized systems.

While the EL6648MSS excels in extreme durability, for applications requiring a larger screen size in more controlled environments, the 12.1-inch G121STN01.0 may be a relevant consideration.

Technical Deep Dive

The Intrinsic Resilience of Inorganic Thin Film Electroluminescent Technology

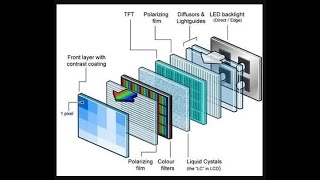

The exceptional durability of the EL6648MSS stems from its fundamental technology. Unlike TFT-LCD technology, which relies on organic liquid crystals suspended between layers of glass, TFEL displays are entirely solid-state. The light-emitting layers are inorganic, deposited as thin films. This construction is key to its performance advantages.

This solid-state design eliminates the components susceptible to environmental stress. There are no liquid crystals to freeze, boil, or degrade under UV exposure. An MTBF of over 100,000 hours is not just a number; it is the result of a fundamentally robust architecture. This is like a car engine designed to run continuously for over 11 years without a breakdown, ensuring predictable and low-maintenance operation in the field. The result is a display that maintains its brightness, contrast, and response time across its entire operating temperature range, providing a level of performance stability that liquid-crystal-based technologies from manufacturers like AUO cannot match in such extreme conditions.

Frequently Asked Questions

Engineering Questions on TFEL Implementation and Durability

How does the 200 g shock rating of the EL6648MSS translate to real-world application reliability?

The 200 g shock rating signifies that the display's glass and internal structure can withstand significant, sudden acceleration forces without damage. In practice, this means it is suitable for mounting in high-vibration environments such as tracked vehicles, drilling equipment, or aerospace applications, where it can endure repeated impacts and intense shaking that would cause catastrophic failure in standard displays.

What makes a TFEL display like the EL6648MSS a better choice than a wide-temp industrial LCD in sub-zero conditions?

While some industrial LCDs are rated for low temperatures, they often require internal heaters to keep the liquid crystals fluid enough to function, leading to slow startup times and increased power consumption. The EL6648MSS's emissive TFEL technology is instant-on, even at -50°C, with no change in response time or clarity. This provides superior performance and simplifies the thermal design of the end system.

Does the EL6648MSS require a dedicated heater or cooling system for its specified temperature range?

No. One of the primary engineering advantages of the EL6648MSS is that it operates across its entire -50°C to +85°C temperature range without the need for external heaters or coolers. This significantly reduces system complexity, power budget, and potential points of failure, directly lowering the total cost of ownership.

Integrating the EL6648MSS is a strategic decision to de-risk system deployment in harsh environments. This approach prioritizes long-term operational availability and reduces the total cost of ownership over the product's entire lifecycle by eliminating the need for auxiliary thermal management and frequent replacements.