Content last revised on January 4, 2026

FP15R12KE3 IGBT Module: A Technical Review for High-Efficiency Motor Drives

An Engineering-Centric Analysis of the Infineon EconoPIM™ 2 Module

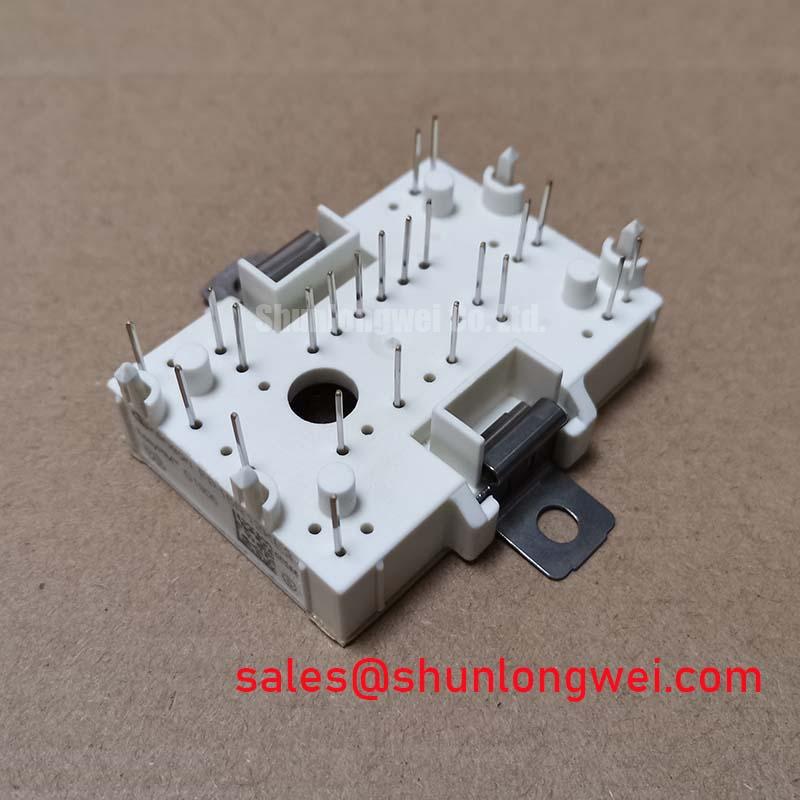

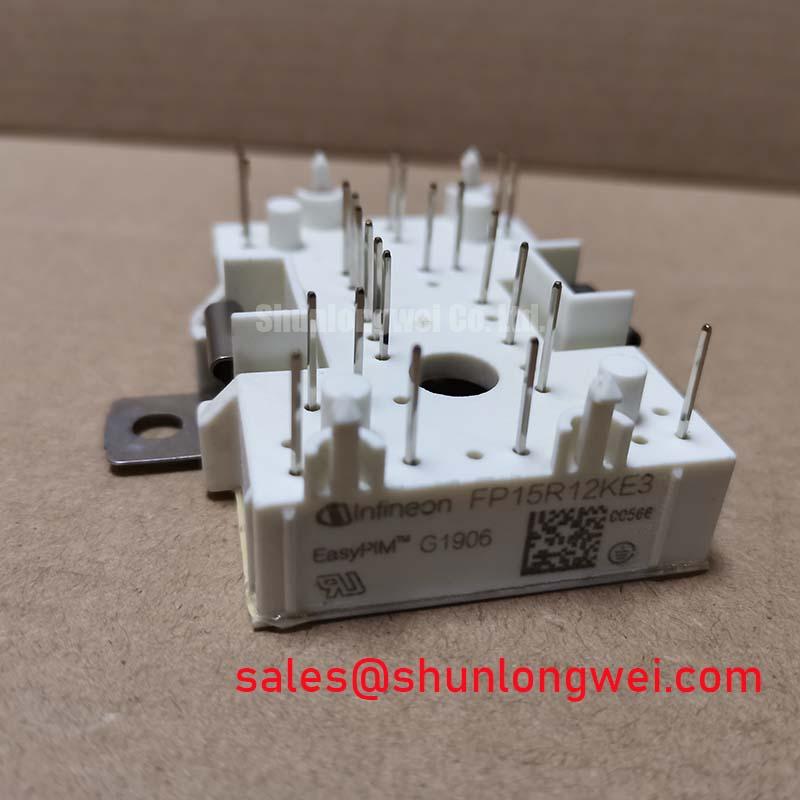

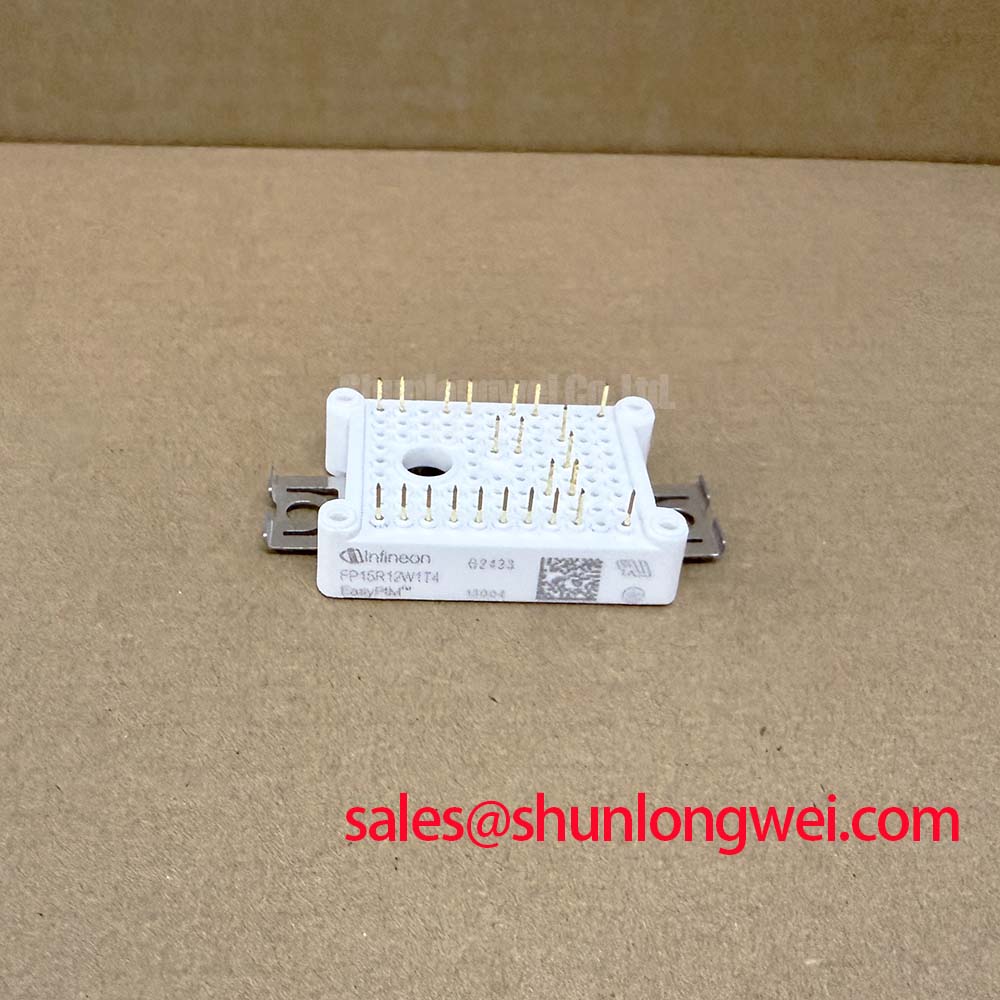

The Infineon FP15R12KE3 is an EconoPIM™ 2 power integrated module, leveraging advanced TrenchSTOP™ IGBT3 technology to deliver a highly efficient and compact power conversion stage. With core specifications of 1200V | 15A | VCEsat (typ) 1.50V, this module provides significant engineering benefits, including minimized switching and conduction losses and integrated real-time thermal sensing. It directly addresses the challenge of designing compact, reliable, and energy-efficient low-power motor drives. For low-power motor drives up to approximately 4kW that demand a superior balance of efficiency and thermal reliability, the FP15R12KE3 represents a benchmark integrated solution.

Key Parameter Overview

Decoding the Specs for Reduced Power Dissipation

The technical specifications of the FP15R12KE3 are foundational to its performance in demanding applications. The following table highlights the critical parameters derived from the official datasheet, with key values emphasized to facilitate engineering evaluation.

| Parameter | Symbol | Condition | Value | Unit |

|---|---|---|---|---|

| Collector-Emitter Voltage | V_CES | T_vj = 25°C | 1200 | V |

| Continuous DC Collector Current | I_C nom | - | 15 | A |

| Collector-Emitter Saturation Voltage | V_CE sat | I_C = 15 A, V_GE = 15 V, T_vj = 25°C | 1.50 (typ.) | V |

| Gate-Emitter Threshold Voltage | V_GE(th) | I_C = 0.25 mA, V_CE = V_GE, T_vj = 25°C | 5.8 (typ.) | V |

| Switching-on Energy | E_on | I_C = 15 A, V_CE = 600 V, V_GE = ±15 V, R_G = 36 Ω, T_vj = 125°C | 1.40 (typ.) | mJ |

| Switching-off Energy | E_off | I_C = 15 A, V_CE = 600 V, V_GE = ±15 V, R_G = 36 Ω, T_vj = 125°C | 1.55 (typ.) | mJ |

| Thermal Resistance, Junction-to-Case | R_thJC | per IGBT | ≤ 0.88 | K/W |

| Short Circuit Withstand Time | t_Psc | V_GE ≤ 15 V, V_CC = 800 V, T_vj ≤ 150°C | ≥ 10 | µs |

Download the FP15R12KE3 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Compact Variable Frequency Drives (VFDs)

The FP15R12KE3 is engineered for low-power applications where efficiency and power density are critical design constraints. Its primary application is in compact Variable Frequency Drives (VFDs) and servo drives used in industrial automation, such as conveyor systems, pumps, fans, and textile machinery. What is the core benefit of the FP15R12KE3's IGBT3 technology? It minimizes power losses for higher system efficiency.

Consider the engineering challenge of designing a VFD for an AC induction motor within a space-constrained, fanless enclosure. Thermal management becomes the dominant issue. The FP15R12KE3 directly addresses this through its low V_CEsat and optimized switching characteristics. The low on-state voltage drop reduces conduction losses, which are a major source of heat during motor operation. This reduction in waste heat allows engineers to specify a smaller heatsink or even consider passive cooling solutions, directly reducing system size, cost, and audible noise. Furthermore, the integrated three-phase rectifier, brake chopper, and inverter simplify the overall power stage design, reducing assembly time and potential points of failure. For systems that require higher current handling for more demanding motors, the related FP25R12KE3 offers a 25A capability within the same EconoPIM™ 2 family.

Technical Deep Dive

Analyzing the Efficiency Gains from TrenchSTOP™ IGBT3 Technology

The performance of the FP15R12KE3 is fundamentally enabled by Infineon TRENCHSTOP™ IGBT3 technology. This generation of IGBTs represents a significant advancement in achieving an optimal trade-off between the two primary sources of power loss: conduction and switching.

Conduction loss, determined by the V_CEsat, can be understood using the analogy of a water pipe's friction. A lower V_CEsat is like a wider, smoother pipe; it allows electrical current to flow with less resistance, which in turn generates significantly less heat. The FP15R12KE3's typical V_CEsat of 1.50V (at nominal current and 25°C) is a strong indicator of low on-state power dissipation.

Switching losses (E_on and E_off) occur during the brief transitions between the on and off states. Imagine these losses as the "splash" of water when a faucet is turned on or off. A conventional switch might cause a large splash, wasting water. The TrenchSTOP™ IGBT3 acts like a high-performance valve, minimizing this energy "splash" during every Pulse Width Modulation (PWM) cycle. This is particularly crucial in modern motor drives that use higher switching frequencies for better motor control and reduced audible noise, as each "splash" adds up, contributing to the total heat load on the system. By optimizing this balance, the FP15R12KE3 enables higher operational efficiency, which is a key requirement for meeting stringent energy consumption standards.

Frequently Asked Questions (FAQ)

How does the TrenchSTOP™ IGBT3 technology in the FP15R12KE3 contribute to lower total power losses compared to previous generation IGBTs?

TrenchSTOP™ IGBT3 technology is specifically designed to provide a much better balance between low collector-emitter saturation voltage (V_CEsat) and low switching energies (E_on/E_off). This means it generates less heat both when it is fully conducting current and during the rapid transitions between on and off states, resulting in higher overall efficiency for the inverter.

What is the practical benefit of the integrated NTC thermistor for a VFD design?

The integrated NTC thermistor provides a direct, real-time measurement of the module's internal temperature. This allows the drive's control system to implement precise over-temperature protection, preventing catastrophic failures. How does the integrated NTC enhance reliability? It allows precise real-time temperature monitoring to prevent overheating. This data can also be used for active thermal management, such as adjusting fan speed or de-rating power output gracefully if the system approaches its thermal limits.

Is the FP15R12KE3 suitable for applications with high PWM switching frequencies?

Yes, within limits. The TrenchSTOP™ IGBT3 technology offers low switching losses, making it well-suited for typical motor drive frequencies (e.g., 4 kHz to 16 kHz). Operating at higher frequencies can improve motor performance but will increase total switching losses. Engineers should use the E_on and E_off values from the datasheet to calculate the expected thermal load at their target frequency and ensure their heatsink design is adequate.

The datasheet specifies a V_CEsat of 1.50V at 25°C. How does this value change at higher operating temperatures and what is the design implication?

The FP15R12KE3 datasheet indicates a positive temperature coefficient for V_CEsat. This means as the IGBT's junction temperature increases to its typical operating range (e.g., 125°C), the V_CEsat will also increase. This characteristic is highly beneficial when paralleling modules, as it helps to ensure natural current balancing. For a single module, engineers must use the performance curves in the datasheet to calculate conduction losses at the actual operating temperature, not just the 25°C value, to ensure an accurate thermal design.

Strategic Fit for Modern Industrial Automation

The integration of a complete three-phase inverter, brake, and rectifier into a single, thermally efficient package like the FP15R12KE3 aligns perfectly with the industry trend towards higher power density and modularity. By providing a pre-validated power stage with well-defined thermal and electrical characteristics, this module allows design engineers to accelerate their development cycle and focus on system-level features like advanced motor control algorithms and network connectivity. The underlying efficiency of the TrenchSTOP™ IGBT3 technology not only reduces immediate energy costs but also contributes to enhanced long-term system reliability by lowering thermal stress on all surrounding components.