Content last revised on November 12, 2025

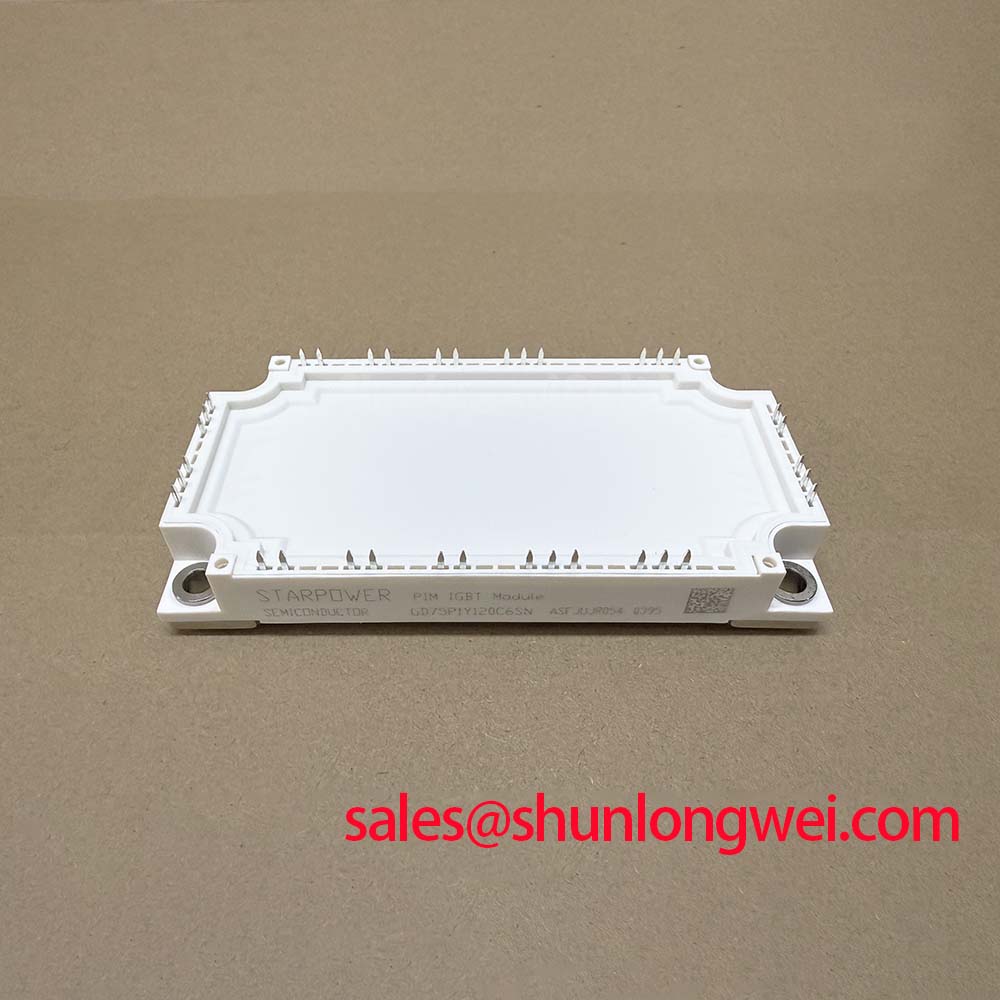

STARPOWER GD300MLX65B3ST | 650V Six-Pack IGBT for High-Efficiency Motor Drives

The STARPOWER GD300MLX65B3ST is a high-performance 650V, 300A six-pack IGBT module engineered to meet the demanding requirements of modern, high-efficiency power conversion systems. Leveraging advanced chip technology and robust packaging, this module delivers a superior balance of low power loss, high reliability, and excellent thermal performance, making it an ideal choice for compact and powerful inverter designs.

Technical Deep Dive: Engineering for Performance

At the core of the GD300MLX65B3ST lies STARPOWER's 4th generation Trench Field-Stop (TFS) IGBT technology. This sophisticated silicon design is not a mere incremental update; it represents a fundamental optimization for high-current, medium-frequency applications. The trench gate structure significantly reduces the on-state voltage drop, or VCE(sat), minimizing conduction losses. Simultaneously, the field-stop layer allows for a thinner N-drift region, which drastically reduces the turn-off switching energy (Eoff). The direct engineering benefit is a reduction in total power loss, which allows designers to either increase the system's output power, improve its overall energy efficiency, or reduce the size and cost of the required heatsink.

Furthermore, the module incorporates a co-packaged freewheeling diode (FWD) that is perfectly matched to the IGBT. It exhibits soft recovery characteristics, which is critical for minimizing electromagnetic interference (EMI) and reducing voltage overshoots during switching transitions. This inherent softness can simplify or even eliminate the need for external snubber circuits, saving both component cost and valuable PCB real estate.

Key Parameter Overview: GD300MLX65B3ST

The following table outlines the critical electrical and thermal characteristics that define the module's performance envelope. For a comprehensive analysis and application notes, you can download the complete GD300MLX65B3ST datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 650 V |

| Continuous Collector Current (IC @ TC=100°C) | 300 A |

| Collector-Emitter Saturation Voltage (VCE(sat), typ. @ 300A, 150°C) | 1.60 V |

| Short-Circuit Withstand Time (tSC) | ≥ 10 µs |

| Thermal Resistance, Junction-to-Case (Rth(j-c) per IGBT) | 0.14 °C/W |

| Isolation Voltage (Vis, AC, 1 min.) | 2500 V |

Application Scenarios & Value Proposition

The specific characteristics of the STARPOWER GD300MLX65B3ST make it exceptionally well-suited for several key applications:

- Industrial Motor Drives: As the core of a Variable Frequency Drive (VFD), its low conduction losses directly improve system efficiency, especially in high-torque, low-speed scenarios. The 10µs short-circuit rating provides the necessary ruggedness to withstand motor stalls and fault conditions.

- Welding Power Supplies: The high current handling and robust thermal design allow the module to manage the demanding, cyclical loads of modern welding equipment. Its fast, controlled switching enables advanced welding waveforms for superior weld quality.

- Servo Drives: In precision motion control, the module's low switching losses and fast FWD recovery enable higher PWM frequencies. This results in smoother current delivery to the motor, reducing torque ripple and improving positioning accuracy. Further exploration of such applications can be found in our guide to IGBTs in robotic servo drives.

Frequently Asked Questions (FAQ)

Our engineers frequently encounter these questions when designing with high-power IGBT modules like the GD300MLX65B3ST.

- How does the integrated NTC thermistor improve system reliability?

The built-in NTC provides a direct, real-time measurement of the module's baseplate temperature. This data can be fed back to the system controller to implement precise over-temperature protection (OTP). Unlike external sensors, it reflects the thermal state of the die more accurately, preventing catastrophic failures due to thermal runaway and enabling predictive maintenance alerts. - What are the key considerations for the gate drive circuit?

To fully exploit the module's low switching losses, a capable gate drive circuit is essential. It should provide a stable +15V for turn-on and a negative voltage (e.g., -8V to -15V) for a definitive turn-off, which prevents parasitic turn-on induced by the Miller effect. A low-inductance layout and a dedicated Kelvin emitter connection are crucial for clean, fast switching and accurate control.

For detailed selection guidance or to discuss integrating the GD300MLX65B3ST into your next power project, please contact our technical team for expert support.