Content last revised on November 14, 2025

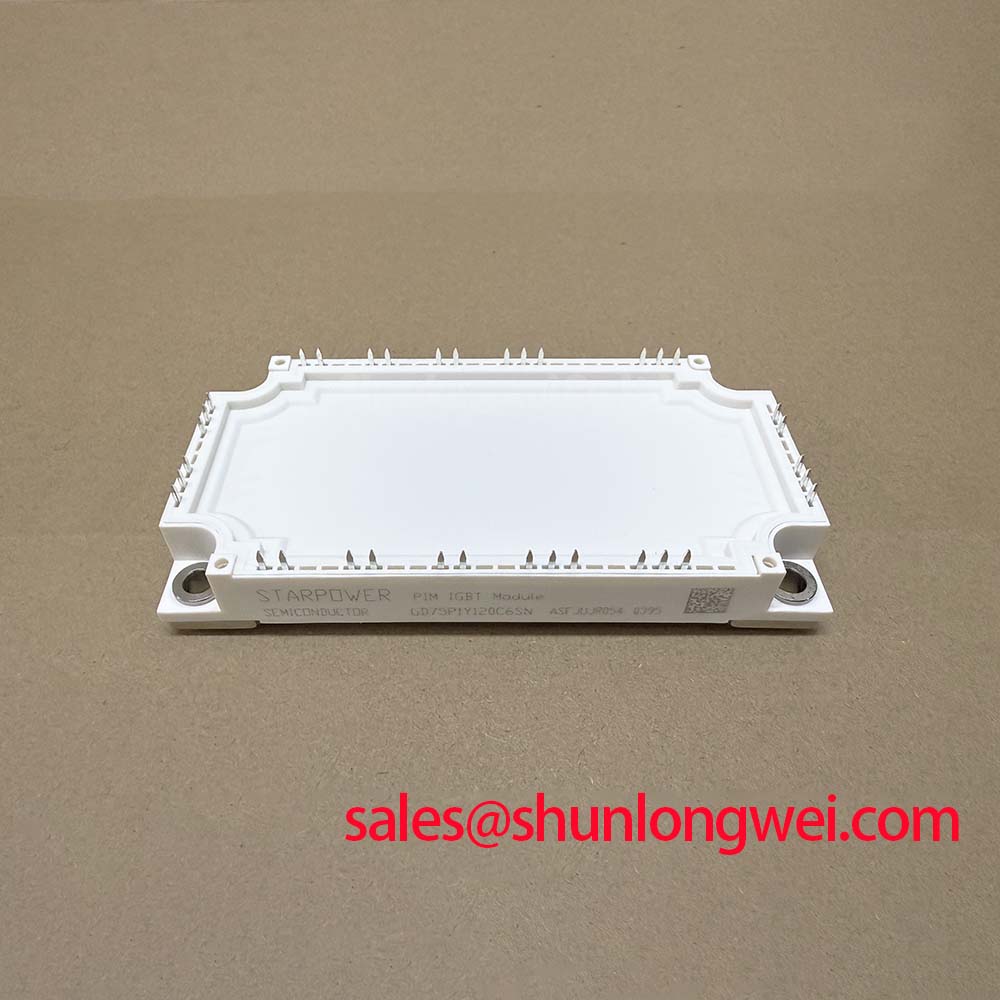

GD75P1Y120C6SN PIM IGBT Module: Datasheet & Thermal Specs

Technical Overview for High-Integrity Power Systems

At the core of efficient power conversion lies precise thermal control. The Starpower GD75P1Y120C6SN is a Power Integrated Module (PIM) IGBT engineered for superior thermal management and operational reliability in compact systems. Its design philosophy prioritizes heat dissipation to ensure stable performance under demanding industrial loads. Key specifications include: 1200V | 75A | Rth(j-c) 0.45°C/W (IGBT). This module delivers enhanced thermal stability and integrated system protection. The integrated NTC thermistor provides critical, real-time temperature feedback to the control logic, enabling proactive fault prevention and extending the system's operational lifespan by mitigating risks of thermal overload.

Strategic Integration for Next-Generation Industrial Drives

The move towards Industry 4.0 and increased automation places immense pressure on the reliability and footprint of power electronics. The GD75P1Y120C6SN directly addresses these trends by consolidating a three-phase rectifier, a three-phase inverter, and a brake chopper into a single, thermally efficient package. This high level of integration aligns with the strategic need for smaller, more reliable motor drives and power converters. For system architects, this translates to a reduced bill of materials (BOM), simplified assembly, and a more predictable thermal profile, which are pivotal advantages in developing competitive and robust industrial automation solutions.

A Data-Centric Look at PIM Module Selection

When evaluating integrated power modules, a direct comparison of datasheet parameters provides the necessary data for an informed engineering decision. The following table offers a factual side-by-side look at key specifications. This data is presented to support your analysis process without offering a direct recommendation, empowering you to select the component that best aligns with your specific design constraints, such as thermal headroom, switching frequency, and required current capacity.

| Part Number | V_CES (Collector-Emitter Voltage) | I_C (Continuous Collector Current @ Tc=80°C) | V_CE(sat) (Typ @ I_C=75A) | Configuration |

|---|---|---|---|---|

| GD75P1Y120C6SN | 1200V | 75A | 1.85V | PIM (3-ph Rectifier + 3-ph Inverter + Brake + NTC) |

| GD50PIY120C6SN | 1200V | 50A | 1.85V | PIM (3-ph Rectifier + 3-ph Inverter + Brake + NTC) |

Design-In Focus: Maximizing Reliability with the GD75P1Y120C6SN

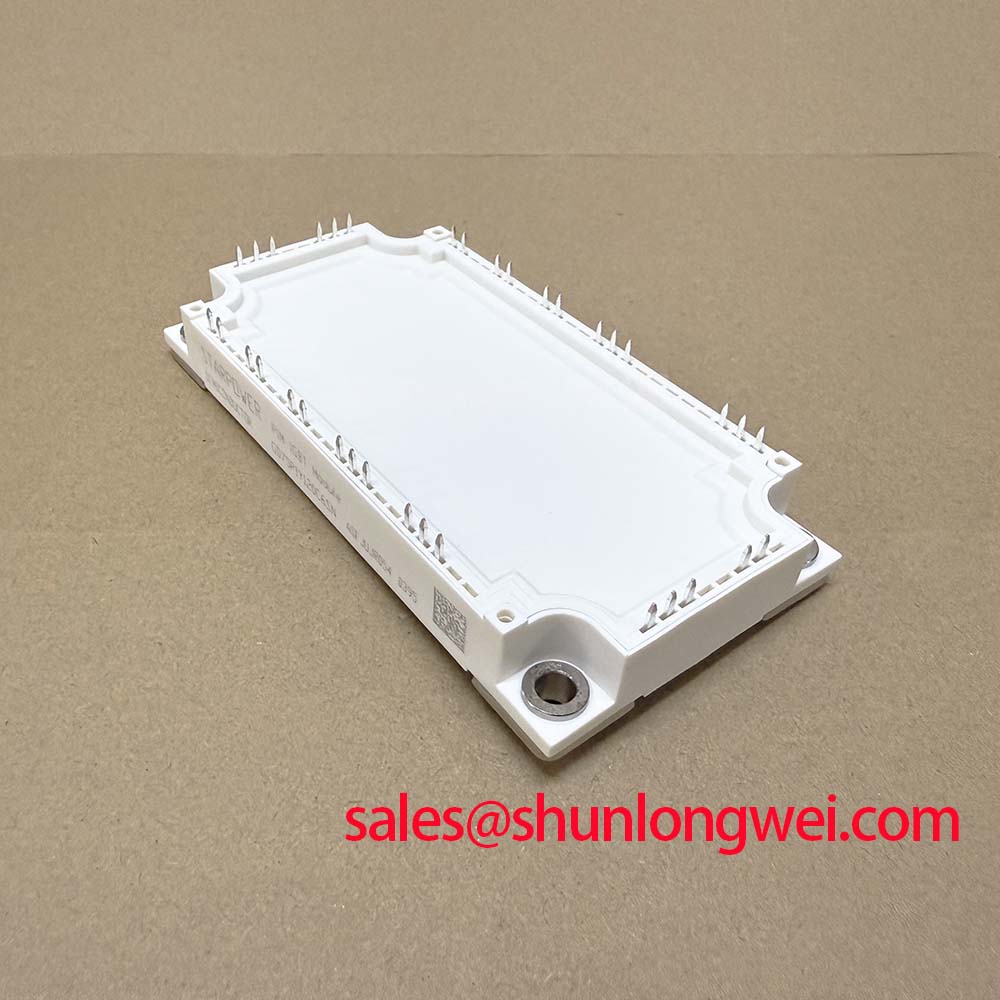

Successfully deploying the GD75P1Y120C6SN hinges on leveraging its inherent thermal management features. The module's foundation on a Direct Bonded Copper (DBC) substrate provides both high electrical isolation and an efficient thermal pathway. What is the primary benefit of its pressure-contact design? It's the enhancement of long-term reliability by creating a solid thermal interface. To capitalize on this, engineers should ensure proper mounting procedures, including the use of a high-quality thermal interface material (TIM) and adherence to specified torque values for the mounting screws. This practice minimizes contact resistance, ensuring the module's low junction-to-case thermal resistance is fully realized in the final application, directly contributing to a longer service life.

Anatomy of Thermal Excellence: A Technical Breakdown

The performance and longevity of an IGBT module are inextricably linked to its thermal design. The GD75P1Y120C6SN incorporates several features aimed at optimizing heat dissipation and providing system-level protection.

Low Thermal Resistance (Rth(j-c))

The module specifies a junction-to-case thermal resistance of 0.45°C/W for the IGBT and 0.7°C/W for the diode. This parameter is analogous to the width of a pipeline; a lower value signifies a wider pipe, allowing heat to flow more freely from the silicon chip to the heatsink. This efficiency in heat transfer is crucial for keeping junction temperatures below the maximum limit, especially under heavy load conditions, which is fundamental for long-term reliability. Why is low thermal resistance critical? It ensures efficient heat dissipation, improving reliability and power density.

Integrated NTC Thermistor

Embedded within the module is a Negative Temperature Coefficient (NTC) thermistor. This component acts as an on-board thermal sensor. Its resistance changes predictably with temperature (rated at 5 kΩ at 25°C), providing a direct feedback loop to the system's microcontroller. This allows for the implementation of sophisticated thermal management strategies, such as derating power output or triggering a controlled shutdown if temperatures exceed safe limits, preventing catastrophic failure.

High Maximum Junction Temperature (Tj,max)

The module is rated for a maximum operating junction temperature of 175°C. This high thermal ceiling provides a significant safety margin in demanding industrial environments where ambient temperatures can be elevated. It gives designers more flexibility in their thermal design and ensures the module can withstand transient power spikes without immediate degradation.

Technical Inquiries for the GD75P1Y120C6SN

1. What is the specific NTC resistance (R25) for the GD75P1Y120C6SN?

According to the official datasheet, the integrated NTC thermistor has a nominal resistance of 5 kΩ at a temperature of 25°C, with a B-value (B25/50) of 3375 K. This allows for accurate temperature monitoring when integrated with a corresponding control circuit.

2. How does the GD75P1Y120C6SN's PIM design simplify the development of a compact motor drive?

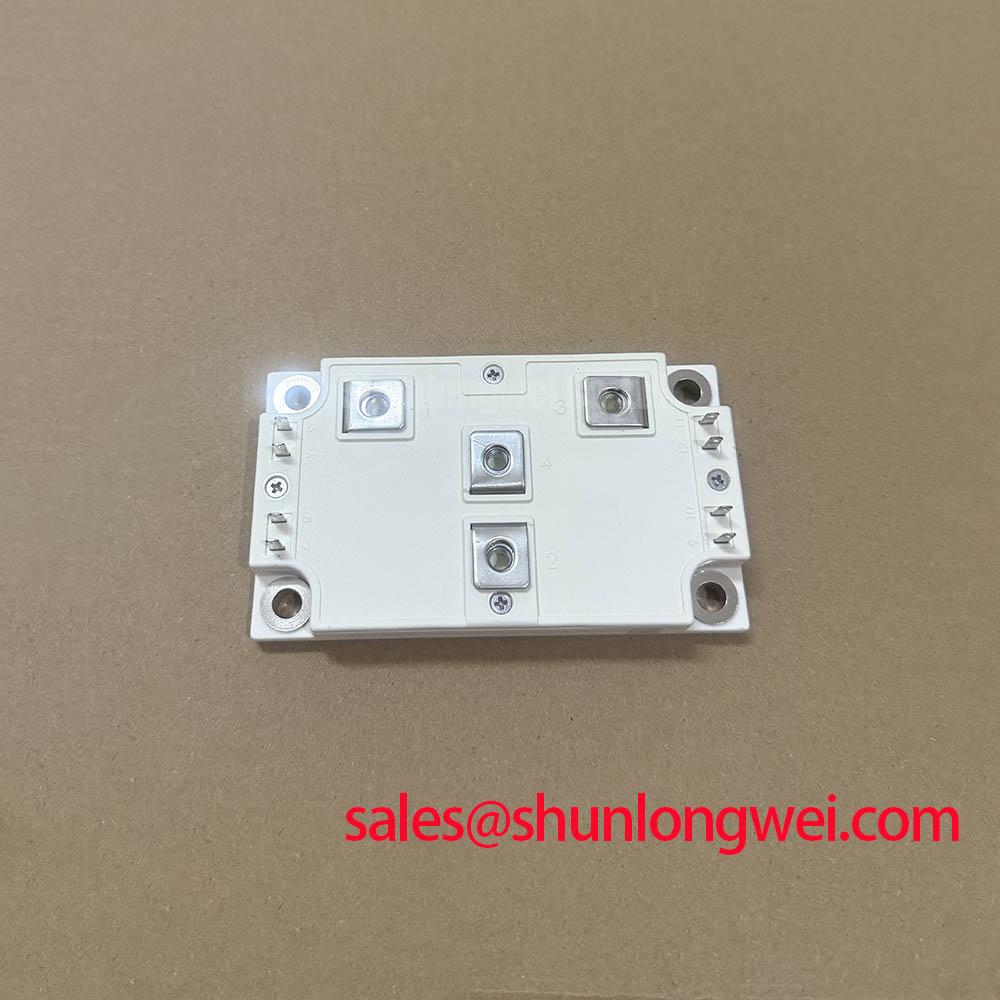

The PIM (Power Integrated Module) architecture combines the AC-DC rectification stage, the DC-AC inversion stage, and the dynamic braking chopper into one component. This significantly reduces the PCB footprint, simplifies the bus bar layout, minimizes assembly time, and reduces stray inductance compared to a solution built from discrete components. For a deeper dive into module selection, consider reading our guide on decoding IGBT datasheets.

3. What are the key considerations for mounting this module to a heatsink to ensure optimal thermal performance?

To achieve the specified low thermal resistance, it is critical to ensure a flat and clean heatsink surface (recommended roughness ≤ 5 µm). A uniform layer of thermal interface material (TIM) with a recommended thickness of 50-100 µm should be applied. Finally, the mounting screws should be tightened evenly and to the specified torque value (typically 3.5 - 4.5 Nm) to ensure consistent pressure without causing mechanical stress to the module's substrate.

Core Specifications for System Evaluation

The data presented here is derived from the official manufacturer's datasheet. For complete electrical and thermal characteristics, please refer to the downloadable PDF.

Inverter Section (per Switch)

- Collector-Emitter Voltage (V_CES): 1200V

- Continuous Collector Current (I_C, @ Tc = 80°C): 75A

- Collector-Emitter Saturation Voltage (V_CE(sat), Typ. @ I_C = 75A, Tj = 25°C): 1.85V

Rectifier Section (per Diode)

- Repetitive Peak Reverse Voltage (V_RRM): 1600V

- Average Forward Current (I_FAV): 75A

Brake Chopper Section

- Collector-Emitter Voltage (V_CES): 1200V

- Continuous Collector Current (I_C, @ Tc = 80°C): 40A

Thermal and Mechanical Properties

- Isolation Voltage (V_isol, AC, 1 min.): 2500V

- Max. Junction Temperature (T_jmax): 175°C

- Datasheet: Download the GD75P1Y120C6SNF Datasheet

Empowering Compact and Reliable Power Systems

The GD75P1Y120C6SN is engineered for applications where space, thermal performance, and long-term reliability are primary design drivers. Its integrated nature and robust thermal characteristics make it a strong candidate for a variety of power conversion systems.

Primary Application Areas

- Variable Frequency Drives (VFDs): The all-in-one configuration is ideal for compact motor drives used in industrial automation, HVAC systems, and pumps.

- Servo Drives: High power density and integrated braking support the dynamic performance requirements of precision motion control systems.

- Uninterruptible Power Supplies (UPS): The module's reliability and integrated rectifier and inverter stages contribute to building robust and efficient power backup solutions.

- Welding Power Supplies: The module's robust thermal design can handle the demanding, cyclical loads characteristic of welding applications.

For motor drives up to 30 kW requiring integrated braking and temperature monitoring, the GD75P1Y120C6SN is a technically sound choice due to its low Rth(j-c) of 0.45°C/W.

To further explore the engineering principles behind thermal performance, our article on Why Rth Matters provides additional context. For any questions regarding the integration of the GD75P1Y120C6SN into your design, please consult the datasheet or contact us for further technical information.