Content last revised on November 20, 2025

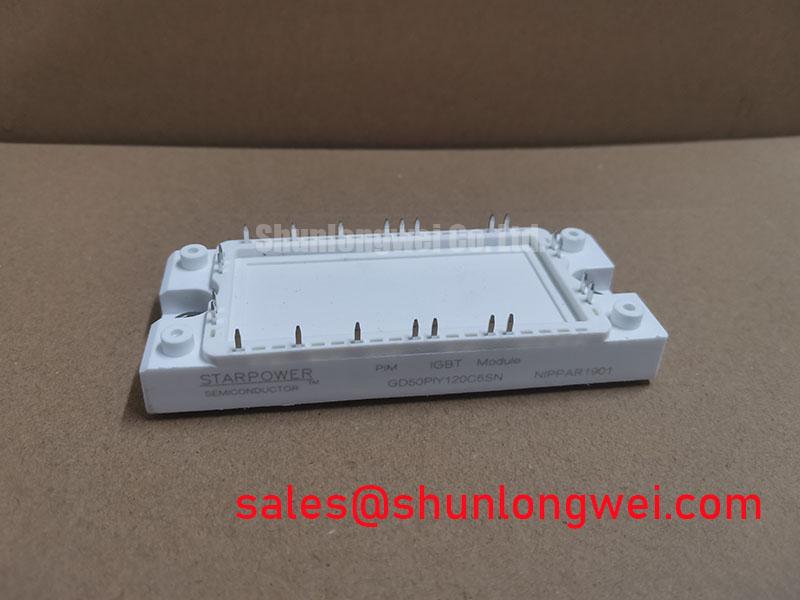

GD50PIY120C6SN | 1200V 50A IGBT Power Integrated Module | Engineering Review

An In-Depth Analysis for Power System Design Engineers

Engineered for compact power conversion systems, the Fuji Electric GD50PIY120C6SN is a 6th generation V-series Power Integrated Module (PIM) that streamlines design while delivering exceptional thermal performance. This module integrates a three-phase converter, a three-phase inverter, and a brake chopper into a single package, offering key specifications of 1200V | 50A | Rth(j-c) of 0.49 °C/W (IGBT). Key benefits include a significantly simplified assembly process and enhanced operational reliability. For engineers questioning how to manage thermal loads in space-constrained motor drives, the module's low thermal resistance provides a direct path to more efficient heatsinking and greater power density. With its integrated NTC thermistor and optimized internal layout, this PIM is the optimal choice for cost-sensitive, high-reliability variable frequency drives up to the 15 kW class.

Application Scenarios & Value

System-Level Benefits in Compact Motion Control Systems

The GD50PIY120C6SN is engineered to address the core challenges in modern, compact power electronics, such as those found in servo drives for CNC machinery, integrated motor drives, and small general-purpose inverters. In these applications, mounting space is at a premium, and thermal management is a critical factor dictating both performance and long-term reliability. A key engineering challenge is efficiently extracting waste heat from the power stages to prevent thermal throttling or premature failure.

This is where the module's low thermal resistance, Rth(j-c) of 0.49 °C/W for the inverter IGBT, provides a distinct advantage. This parameter acts like a wide-gauge pipe for heat, allowing it to flow more easily from the semiconductor chip to the heatsink. This superior thermal transfer allows designers to either reduce the size of the required heatsink, contributing to overall system miniaturization, or to operate the device with a greater thermal margin, enhancing system robustness under heavy load conditions. By integrating the input rectifier, output inverter, and brake circuit, the GD50PIY120C6SN also drastically reduces the required PCB area and simplifies the bus bar design, directly contributing to a smaller final product and lower assembly costs. While this module provides a complete 7-in-1 solution, for applications requiring a different topology but similar power handling, the 7MBR50SB120 offers a 7-pack configuration at the same 1200V/50A rating.

Key Parameter Overview

Decoding the Specs for Thermal and Electrical Performance

The technical specifications of the GD50PIY120C6SN are tailored for efficient and reliable power switching. The following table highlights the critical parameters that directly influence system design, based on conditions of Tvj=25°C unless otherwise specified.

| Parameter | Symbol | Value | Conditions |

|---|---|---|---|

| Collector-Emitter Voltage | Vces | 1200V | |

| Continuous Collector Current | Ic | 50A | Tc = 80°C |

| Collector-Emitter Saturation Voltage (Typ.) | VCE(sat) | 1.80V | Ic = 50A, VGE = 15V, Tvj = 25°C |

| Thermal Resistance (Inverter IGBT) | Rth(j-c) | 0.49 °C/W | Per chip |

| Thermal Resistance (Inverter FWD) | Rth(j-c) | 0.77 °C/W | Per chip |

| Turn-On Switching Energy (Typ.) | Eon | 6.8 mJ | Ic = 50A, Vcc=600V, Tvj=125°C |

| Turn-Off Switching Energy (Typ.) | Eoff | 7.2 mJ | Ic = 50A, Vcc=600V, Tvj=125°C |

| Operating Junction Temperature | Tvjop | -40 to +150°C |

Note: These parameters are for reference. For detailed specifications and performance curves, always consult the official manufacturer's documentation.

Download the GD50PIY120C6SN datasheet for detailed specifications and performance curves.

Technical Deep Dive

The Engineering Advantage of a Power Integrated Module (PIM) Architecture

The architecture of the GD50PIY120C6SN is a prime example of strategic integration in power electronics. By co-packaging the three-phase diode bridge rectifier, the three-phase IGBT inverter, a brake chopper IGBT, and an NTC thermistor, Fuji Electric has created a component that solves multiple system-level problems simultaneously. This PIM design significantly reduces stray inductance in the DC-link path between the rectifier and inverter stages compared to a discrete solution. Lower stray inductance is critical for minimizing voltage overshoots during high-speed switching, which in turn enhances the reliability of the IGBTs and reduces the need for bulky snubber circuits.

Furthermore, the integrated NTC thermistor provides a direct, real-time measurement of the module's substrate temperature. This is far more accurate than an external sensor placed on the heatsink. It enables the implementation of precise over-temperature protection within the drive's control logic, a key requirement of safety standards like Variable Frequency Drive (VFD) regulations. Thinking of VCE(sat) as electrical "friction," the low typical value of 1.80V means less power is wasted as heat during conduction, directly improving the system's overall energy efficiency and further alleviating the thermal burden on the cooling system.

Frequently Asked Questions (FAQ)

What is the primary benefit of using a PIM like the GD50PIY120C6SN over discrete components?

The primary benefit is system simplification. A PIM reduces component count, minimizes PCB footprint, shortens assembly time, and lowers stray inductance, leading to a more compact, reliable, and cost-effective final design for applications like a Servo Drive.

How does the integrated NTC thermistor improve system reliability?

The integrated NTC thermistor provides a direct and accurate reading of the module's internal temperature. This allows the system's controller to implement precise over-temperature protection, preventing the module from operating beyond its safe limits and significantly enhancing long-term reliability and safety.

What is the significance of the 0.49 °C/W thermal resistance (Rth(j-c))?

This value indicates a highly efficient thermal path from the IGBT chip to the module's baseplate. A lower Rth(j-c) means heat is removed more effectively, allowing for either a smaller heatsink, higher power output in the same footprint, or increased operational life due to lower junction temperatures.

Is the GD50PIY120C6SN suitable for high-frequency switching applications?

This module utilizes Fuji's 6th generation V-series IGBTs, which are optimized for a balance between low conduction losses (VCE(sat)) and switching losses (Eon/Eoff). It is well-suited for typical motor drive applications with Pulse Width Modulation (PWM) frequencies in the range of several kHz up to approximately 15 kHz. For applications requiring significantly higher frequencies, a detailed loss calculation using the datasheet curves is essential to ensure operation within thermal limits.

A Strategic Component for Modern Power Conversion

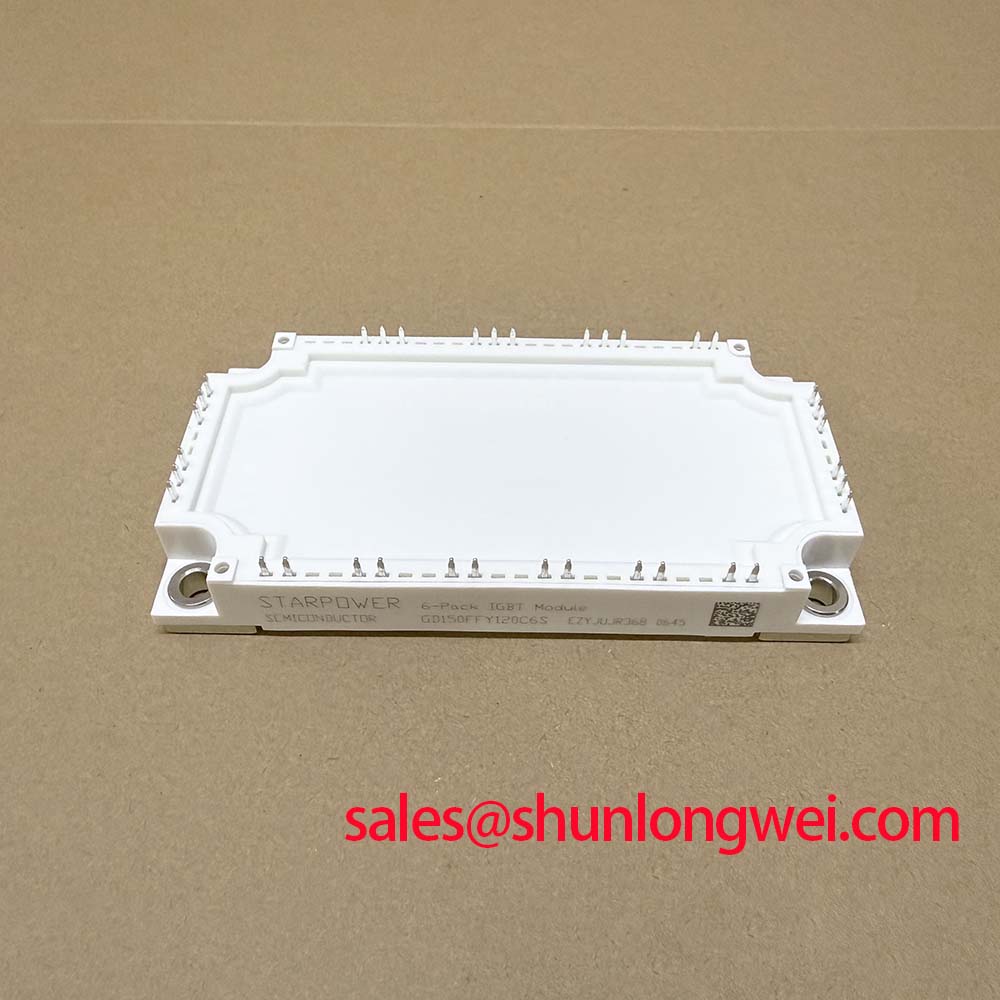

The GD50PIY120C6SN is more than a set of specifications; it represents a strategic design choice. For engineering teams developing next-generation motor controls and power converters, this module offers a clear path to achieving higher power density, improved reliability, and a more streamlined manufacturing process. Its blend of integration and performance makes it a foundational building block for competitive and robust power electronic systems. For systems requiring higher power output, the related GD200HFL120C8SN offers a 200A rating within a similar voltage class.