Content last revised on November 19, 2025

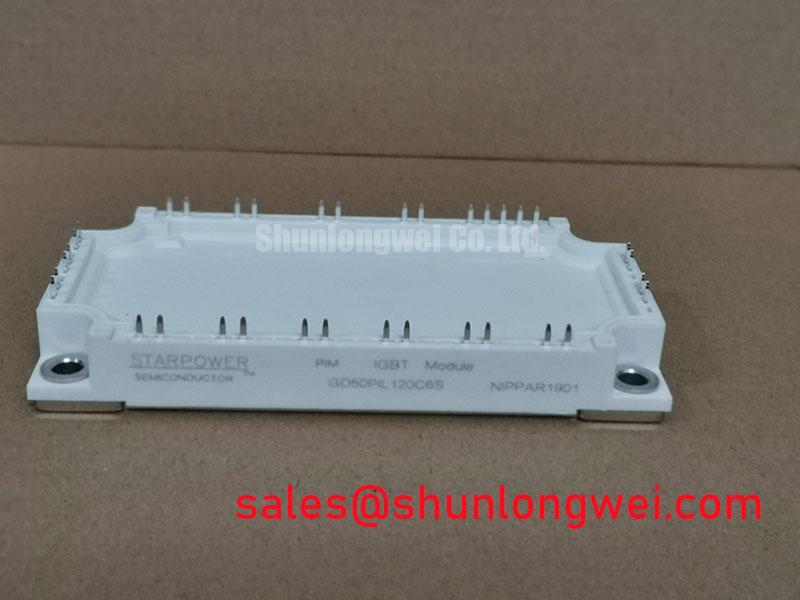

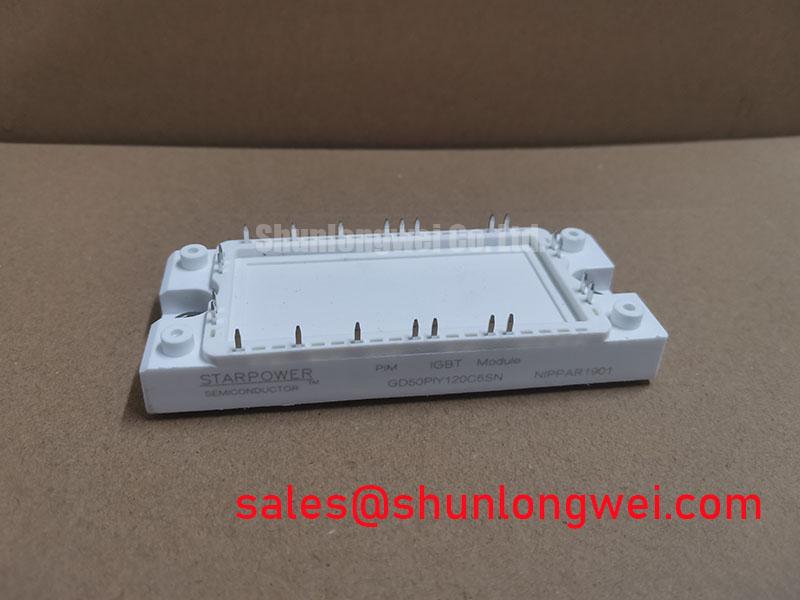

GD50PIL120C6S: 1200V 50A PIM IGBT Module Engineered for High-Efficiency Power Conversion

The STARPOWER GD50PIL120C6S is a Power Integrated Module (PIM) designed for robust performance in high-frequency power systems, integrating a three-phase inverter with a brake chopper and rectifier bridge. This module's core value lies in its use of low VCE(sat) SPT+ IGBT technology to significantly reduce both conduction and switching losses. It operates at 1200V and 50A (at Tc=100°C), featuring key benefits of enhanced thermal efficiency and high system reliability. Answering a critical design question, its positive temperature coefficient and 175°C maximum junction temperature ensure stable operation, making it a dependable choice for demanding industrial applications. For power conversion systems up to 20kW requiring a balance of low conduction and switching losses, the GD50PIL120C6S offers a highly efficient and integrated solution.

Application Scenarios & Value

Achieving System-Level Benefits in Motor Drives and UPS

The GD50PIL120C6S is engineered for applications where efficiency and reliability are paramount. Its primary use cases include inverters for motor drives, uninterruptible power supplies (UPS), and AC/DC servo drive amplifiers. In a modern Variable Frequency Drive (VFD), for instance, designers face the constant challenge of minimizing heat dissipation to create more compact and cost-effective systems. The module's low collector-emitter saturation voltage (VCE(sat)) directly addresses this by lowering the power lost as heat during the IGBT's 'on' state. This is analogous to reducing friction in a mechanical system; less energy is wasted, leading to higher overall efficiency and a reduced need for bulky, expensive heatsinking solutions. The integrated fast and soft reverse recovery anti-parallel freewheeling diode further enhances performance by minimizing switching losses and electromagnetic interference (EMI), simplifying the design of peripheral filtering circuits. For systems requiring higher current handling, the related GD100HFL120C2S offers a solution with a higher current rating within a similar voltage class.

Key Parameter Overview

Decoding the Specs for Thermal Stability and Efficiency

The technical specifications of the GD50PIL120C6S are tailored for robust and efficient power switching. The values below, extracted from the official datasheet, highlight the module's capability to perform under demanding thermal and electrical conditions.

| Parameter | Symbol | Condition | Value | Unit | Engineering Significance |

|---|---|---|---|---|---|

| Collector-Emitter Voltage | VCES | Tj=25°C | 1200 | V | Provides a safe operating margin for standard 380V/400V three-phase industrial mains. |

| Collector Current (DC) | IC | TC=100°C | 50 | A | Defines the continuous current handling capability at a realistic case temperature. |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC=50A, VGE=15V, Tj=150°C | 2.1 (Typ.) | V | A low typical value signifies minimal power loss during conduction, directly improving system efficiency. |

| Maximum Junction Temperature | Tj max | - | 175 | °C | High thermal headroom allows for greater reliability and operational stability in harsh industrial environments. |

| Short-Circuit Withstand Time | tsc | VGE ≤ 15V, VCC ≤ 800V, Tj=150°C | 10 | µs | Ensures the module can survive critical fault conditions, enhancing overall system ruggedness. |

| Total Switching Energy | Ets | IC=50A, VCC=600V, Tj=150°C | 5.8 (Typ.) | mJ | Indicates low energy loss during turn-on and turn-off, making it suitable for higher frequency operation. |

Download the GD50PIL120C6S datasheet for detailed specifications and performance curves.

Technical Deep Dive

The Advantage of an Integrated PIM Architecture

The GD50PIL120C6S utilizes a Power Integrated Module (PIM) design, which co-packages the input rectifier, brake chopper, and output inverter stages into a single, compact housing. This architecture offers significant system-level advantages over using discrete components. By integrating these functions, the physical loop area for current is drastically reduced, which in turn minimizes parasitic inductance. Lower inductance leads to reduced voltage overshoot during high-speed switching events, improving reliability and lowering EMI. Think of it as shortening the pipes in a plumbing system to prevent water hammer—the shorter, direct paths in the PIM prevent dangerous electrical surges. This integration simplifies the PCB layout, reduces component count, and streamlines the manufacturing assembly process, ultimately contributing to a more reliable and cost-effective end product.

Frequently Asked Questions (FAQ)

What is the primary benefit of the low VCE(sat) SPT+ IGBT technology used in the GD50PIL120C6S?

The primary benefit is significantly reduced conduction loss. This means less energy is converted into waste heat when the IGBT is active, leading to higher overall system efficiency and potentially smaller heatsink requirements.

How does the 175°C maximum junction temperature impact system design?

A high Tj max of 175°C provides a larger thermal operating margin. This enhances the module's reliability under heavy loads and in high ambient temperature environments, allowing for more robust and durable system designs.

What does the 10μs short-circuit capability mean for my application?

It means the module can withstand a direct short-circuit event for up to 10 microseconds, allowing time for protection circuits to detect the fault and safely shut down the system. This is a critical safety feature that prevents catastrophic failure of the power stage.

How does the integrated rectifier in the GD50PIL120C6S benefit my design?

The integrated three-phase rectifier bridge simplifies the power input stage design. It reduces the number of external components, saves PCB space, and lowers assembly costs compared to a solution using discrete diodes.

Is the GD50PIL120C6S suitable for paralleling to achieve higher current output?

Yes, the module features a positive temperature coefficient for VCE(sat). This characteristic ensures that as a device heats up, its on-state resistance increases slightly, which naturally helps balance current sharing between parallel-connected modules without requiring complex external circuitry.

An Engineer's Perspective

From a design engineering standpoint, the STARPOWER GD50PIL120C6S presents a practical and efficient solution for mid-power converters. Its true strength is the balance it strikes between electrical performance and thermal robustness. The combination of a low VCE(sat) and a high 175°C junction temperature provides tangible design flexibility, enabling either higher power density or increased long-term reliability. The integrated nature of the PIM architecture further simplifies the development cycle, reducing layout complexity and potential sources of EMI. This module is a strong candidate for designs that require a straightforward, reliable, and efficient core for motor control or power supply applications, backed by essential protection features like a 10µs short-circuit withstand time.