Content last revised on November 21, 2025

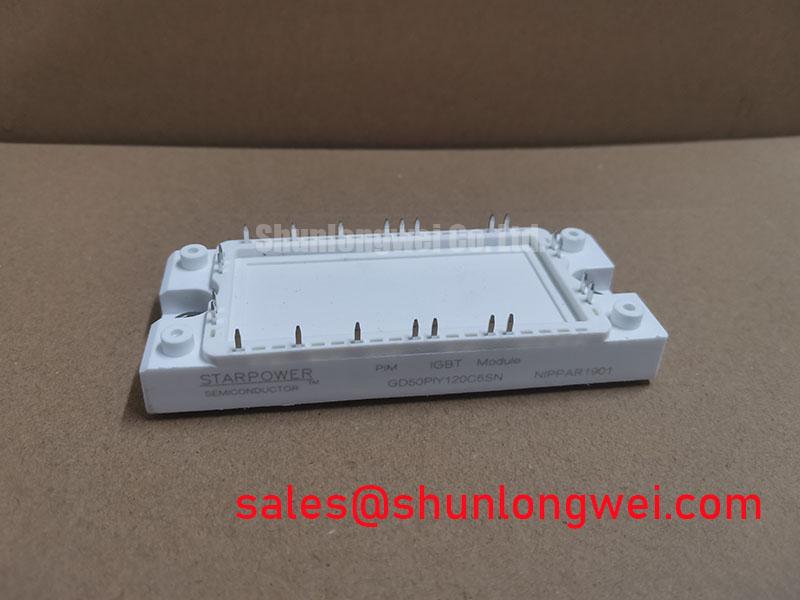

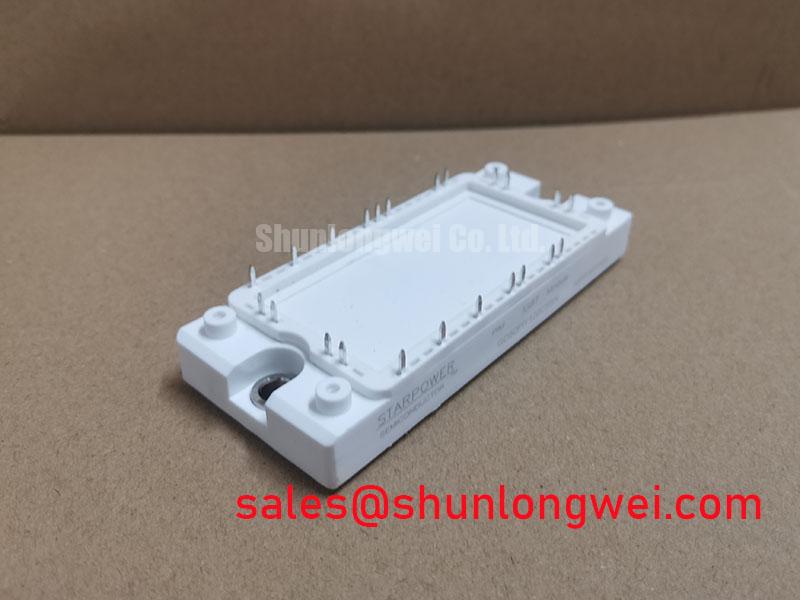

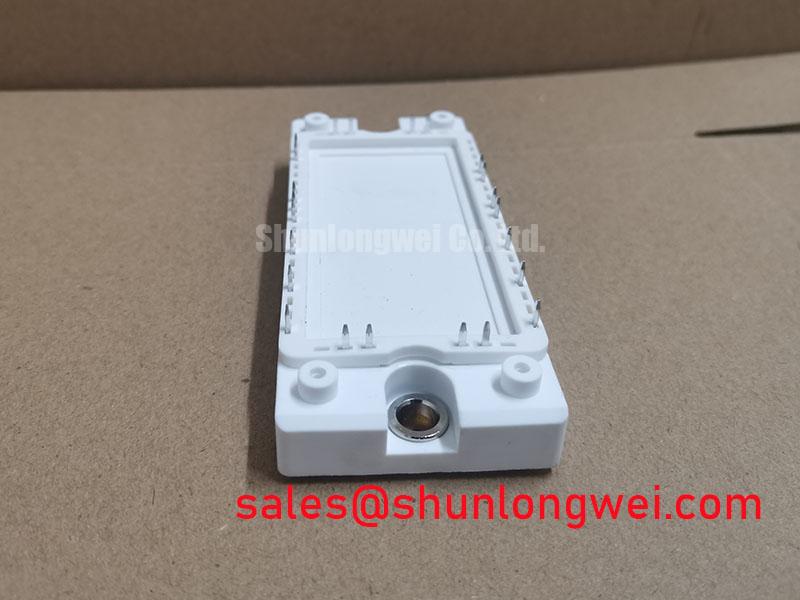

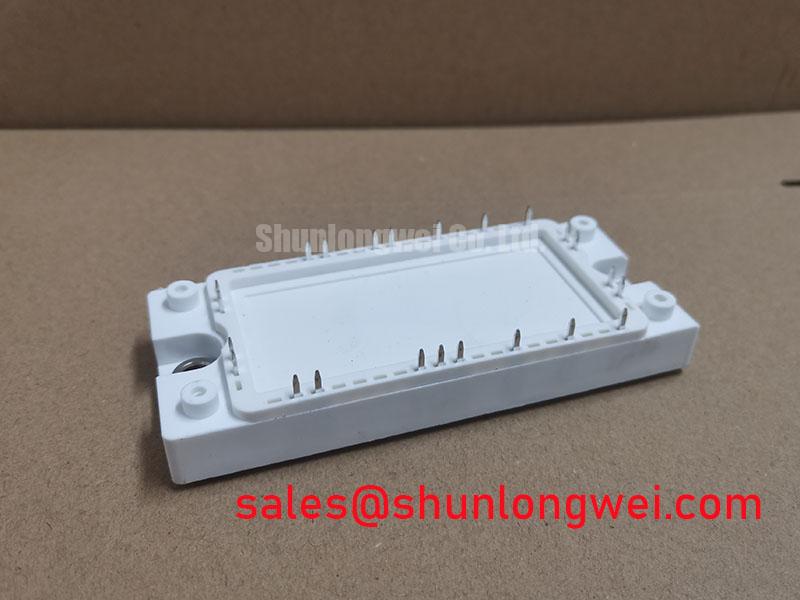

GD50PIY120C5SN: 1200V/50A PIM IGBT Module

M2. Introduction & Key Highlights

The StarPower GD50PIY120C5SN is a Power Integrated Module (PIM) engineered for high-efficiency power conversion, integrating a three-phase input rectifier and a three-phase inverter in a single, thermally efficient package. This device leverages Trench Field Stop IGBT technology to deliver a superior balance between conduction and switching losses, crucial for performance-driven applications. Key specifications include: 1200V Collector-Emitter Voltage | 50A Continuous Collector Current (@ Tc=100°C) | 1.7V VCE(sat) (Typ). The primary engineering benefits are enhanced thermal stability and robust short-circuit protection. This module directly addresses the need for compact and reliable power stages in variable frequency drives. For systems demanding higher power output, the related GD50PIY120C6SN offers a similar voltage rating with increased current handling capabilities. Best Fit: The GD50PIY120C5SN is the optimal choice for motor drives up to 22kW requiring a compact, integrated power stage with high thermal endurance.

B3. Key Parameter Overview

Decoding the Specs for Thermal and Electrical Reliability

The technical specifications of the GD50PIY120C5SN highlight its suitability for demanding industrial applications. The parameters below are critical for design engineers evaluating its performance, particularly concerning thermal management and electrical ruggedness.

| Parameter | Value | Engineering Implication |

| Collector-Emitter Voltage (Vces) | 1200 V | Provides a substantial safety margin for applications running on 380V to 480V AC lines, protecting against voltage transients common in industrial environments. |

| Continuous Collector Current (Ic @ Tc=100°C) | 50 A | Defines the module's capacity for continuous operation under significant thermal load, critical for high-power motor drives and UPS systems. |

| Collector-Emitter Saturation Voltage (VCE(sat) Typ. @ Ic=50A) | 1.7 V | This low saturation voltage directly translates to lower conduction losses, reducing the heat generated by the module. Think of it as electrical friction; a lower value means less energy is wasted as heat, improving overall system efficiency. |

| Maximum Junction Temperature (Tj max) | 175 °C | A high operational temperature ceiling provides greater thermal headroom, enhancing reliability and allowing for more compact heatsink designs or operation in higher ambient temperatures. |

| Short-Circuit Withstand Time (tsc) | 10 µs | This crucial safety feature ensures the module can survive brief, catastrophic short-circuit events, preventing immediate failure and allowing system protection circuits to intervene. |

| Power Dissipation (Pc) | 292 W | Indicates the maximum amount of heat the module can dissipate, a key factor in thermal design and heatsink selection. |

Download the GD50PIY120C5SN datasheet for detailed specifications and performance curves.

B2. Application Scenarios & Value

Achieving System-Level Benefits in Motor Drives and Power Supplies

The GD50PIY120C5SN is engineered to solve critical challenges in modern power electronics. Its integrated PIM design, combining rectifier and inverter stages, is particularly valuable in applications where space and assembly complexity are primary concerns.

A high-fidelity engineering scenario is the design of a compact Variable Frequency Drive (VFD) for industrial conveyor systems. Engineers face the challenge of managing high inrush currents during motor startup while maintaining thermal stability in a confined enclosure. The GD50PIY120C5SN's robust 10µs short-circuit withstand time provides the necessary ruggedness to handle these transient conditions without fault. Furthermore, its positive temperature coefficient of VCE(sat) ensures stable current sharing when paralleling devices is considered, although its 50A rating is often sufficient for mid-power motors. This characteristic simplifies the thermal design, preventing thermal runaway and enhancing the long-term reliability of the VFD. The module's low conduction losses, evidenced by the 1.7V VCE(sat), directly contribute to higher efficiency, reducing the cooling requirements and enabling a smaller overall system footprint.

This module is also highly effective in:

- AC and DC Servo Drive Amplifiers

- Uninterruptible Power Supplies (UPS)

- General Purpose Inverters

For applications requiring lower current, the related GD15PIK120C5S can be considered as a suitable alternative within the same voltage class.

B7. FAQ

Design Considerations for the GD50PIY120C5SN

What is the primary benefit of the module's 175°C maximum junction temperature?

The high Tj max of 175°C provides a significant thermal margin. This allows engineers to design smaller heatsinks, increasing power density, or to operate the module reliably in environments with high ambient temperatures, improving system robustness.

How does the Trench Field Stop IGBT technology impact performance?

This technology, utilized by manufacturers like Infineon, creates a superior trade-off between collector-emitter saturation voltage (VCE(sat)) and switching losses. For the GD50PIY120C5SN, this results in lower overall power loss, which means higher inverter efficiency and reduced thermal stress on the component.

What does the 10µs short-circuit capability mean for system design?

It provides a critical safety window. In the event of a fault like a motor phase-to-phase short, the module can withstand the immense current for up to 10 microseconds. This is ample time for the gate drive protection circuitry to detect the overcurrent condition and safely shut down the IGBT, preventing catastrophic failure.

Is the GD50PIY120C5SN suitable for hard-switching topologies?

Yes, its design for low conduction and switching losses makes it well-suited for hard-switching applications like standard VFDs and UPS systems. The fast and soft reverse recovery characteristics of the integrated freewheeling diodes also help to minimize voltage overshoots and electromagnetic interference (EMI).

What is the significance of the integrated three-phase rectifier?

The integrated rectifier simplifies the overall system design and reduces manufacturing complexity. By including the AC-to-DC conversion stage within the same module as the DC-to-AC inverter, it eliminates the need for a separate rectifier bridge, saving PCB space, reducing component count, and streamlining the assembly process for a Servo Drive.

An Engineer's Perspective

From an engineering standpoint, the GD50PIY120C5SN is a highly practical component that prioritizes reliability and integration. The combination of a high-temperature rating and a robust short-circuit withstand time offers peace of mind in challenging industrial environments. Its PIM architecture streamlines the design process, allowing for more compact and cost-effective power stages without compromising on the thermal and electrical ruggedness required for modern motor control and power conversion systems.