Content last revised on November 21, 2025

GD25PJT120L3S: Integrated 1200V PIM for High-Efficiency Motor Drives

Engineered for compact power systems, the Starpower GD25PJT120L3S is a Power Integrated Module (PIM) that streamlines the design of low-power motor drives and uninterruptible power supplies. It delivers a robust 1200V | 25A rating within a single, thermally efficient package. This integration offers two primary engineering benefits: simplified assembly and enhanced system reliability. By co-packaging the rectifier, brake chopper, and inverter stages, this module directly addresses the challenge of minimizing parasitic inductance in high-frequency switching applications, leading to cleaner performance. For designers developing variable frequency drives under 11kW, this module provides an optimized balance of integration and electrical performance.

Application Scenarios & Value

System-Level Benefits in Compact Industrial Automation

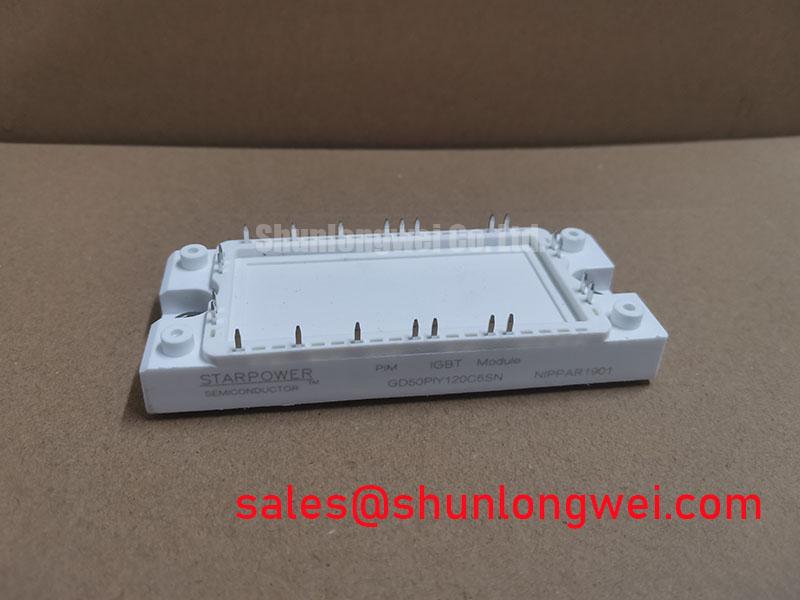

The GD25PJT120L3S is ideally suited for low-power Variable Frequency Drive (VFD) and servo drive applications where footprint and efficiency are paramount. Consider the design of a motor control for a packaging conveyor system. The challenge is to create a compact, reliable drive that fits within a constrained electrical cabinet while minimizing energy consumption. The integrated nature of this PIM is a direct solution; it replaces numerous discrete components, reducing PCB complexity, assembly time, and potential points of failure. Its low collector-emitter saturation voltage (Vce(sat)) of 1.7V (typical at 25°C) reduces conduction losses, which means less heat is generated, allowing for smaller heatsinks and a more compact overall system design. This directly contributes to higher power density and lower operational costs, key objectives in modern industrial automation. While the GD25PJT120L3S is optimized for 25A applications, for systems demanding higher current handling for more powerful motors, the related GD50PIY120C6SN offers a similar integrated topology with a higher current rating.

Key Parameter Overview

Highlighted Specifications for Drive Performance

The technical specifications of the GD25PJT120L3S are tailored for efficient power conversion. The following table highlights the key parameters that directly influence its performance in motor drive applications.

| Parameter | Symbol | Value | Condition |

|---|---|---|---|

| Collector-Emitter Voltage | VCES | 1200 V | Tj = 25°C |

| Continuous Collector Current (Inverter) | IC | 25 A | Tc = 100°C |

| Collector-Emitter Saturation Voltage | VCE(sat) | 1.70 V (typ.) | IC = 25A, Tj = 25°C |

| Short Circuit Withstand Time | tsc | ≥ 10 µs | VCC = 600V, VGE = 15V |

| Max Junction Temperature | Tj,max | 175 °C | - |

| Thermal Resistance, Junction-Case (per IGBT) | Rth(j-c) | 0.50 °C/W | - |

Download the GD25PJT120L3S datasheet for detailed specifications and performance curves.

Industry Insights & Strategic Advantage

Meeting Efficiency Mandates in Motor Control

The push for greater energy efficiency in industrial motors, guided by standards such as IEC 61800-5-1, places significant demands on power electronics. The GD25PJT120L3S is a strategic component for engineers aiming to meet these targets. Its use of Trench Field-Stop IGBT technology is critical. This technology provides a superior trade-off between conduction losses (low VCE(sat)) and switching losses, a key requirement for modern Pulse Width Modulation (PWM) based inverters. By enabling higher switching frequencies without incurring excessive thermal penalties, this module allows for the use of smaller, lighter magnetic components and capacitors, shrinking the overall size of the VFD. The integrated NTC thermistor provides essential temperature feedback, allowing the motor control system to implement protective measures and ensure operational safety and longevity.

Technical Deep Dive

The Engineering Advantage of an Integrated PIM Topology

One of the most significant, yet often overlooked, challenges in power module design is managing parasitic inductance. In a discrete component layout, the physical distance and wiring between the rectifier, brake, and inverter stages introduce stray inductance. Think of this parasitic inductance as small, unwanted coils of hose in a high-pressure plumbing system; they resist sudden changes in current flow, causing pressure spikes (voltage overshoots) that can damage components. The GD25PJT120L3S mitigates this by integrating all three stages into a single, low-inductance package. This architecture provides a much shorter, optimized current path, significantly reducing voltage overshoots during fast switching events. The result is cleaner switching waveforms, reduced EMI generation, and enhanced reliability of the IGBTs and diodes, simplifying the design of snubber circuits and improving overall system robustness.

Frequently Asked Questions (FAQ)

What is the primary function of the integrated brake chopper in the GD25PJT120L3S?

The brake chopper is essential for motor drive applications involving deceleration. When a motor decelerates rapidly, it acts as a generator, feeding energy back into the DC bus. The brake chopper dissipates this regenerative energy through an external braking resistor, preventing the DC bus voltage from rising to dangerous levels and protecting the module and other components.

How does the Rth(j-c) of 0.50 °C/W impact the thermal design of a system?

The thermal resistance from junction to case (Rth(j-c)) is a critical metric for thermal management. A lower value indicates more efficient heat transfer from the semiconductor chip to the module's baseplate. This Rth(j-c) value allows engineers to accurately calculate the required heatsink performance to keep the IGBT junction temperature below the maximum of 175°C under specific load conditions, ensuring long-term operational reliability. You can explore this further in our guide to IGBT selection and thermal management.

What does the positive temperature coefficient of VCE(sat) mean for paralleling modules?

The GD25PJT120L3S features a positive temperature coefficient for VCE(sat), meaning that as an IGBT chip heats up, its on-state voltage drop increases. While this module is not typically designed for paralleling, this characteristic is fundamentally important for thermal stability. If one chip were to get hotter and conduct more current (a negative coefficient), it would lead to thermal runaway. A positive coefficient creates a self-balancing effect, ensuring thermal stability within the module.

Strategic Outlook for System Design

The GD25PJT120L3S represents a design philosophy centered on integration and efficiency. For engineering teams developing next-generation compact motor drives, servo amplifiers, and power conversion systems, this module offers a clear path to reducing system complexity, improving thermal performance, and accelerating time-to-market. Its balanced electrical characteristics and all-in-one construction make it a foundational building block for reliable and energy-conscious industrial applications.