Content last revised on January 4, 2026

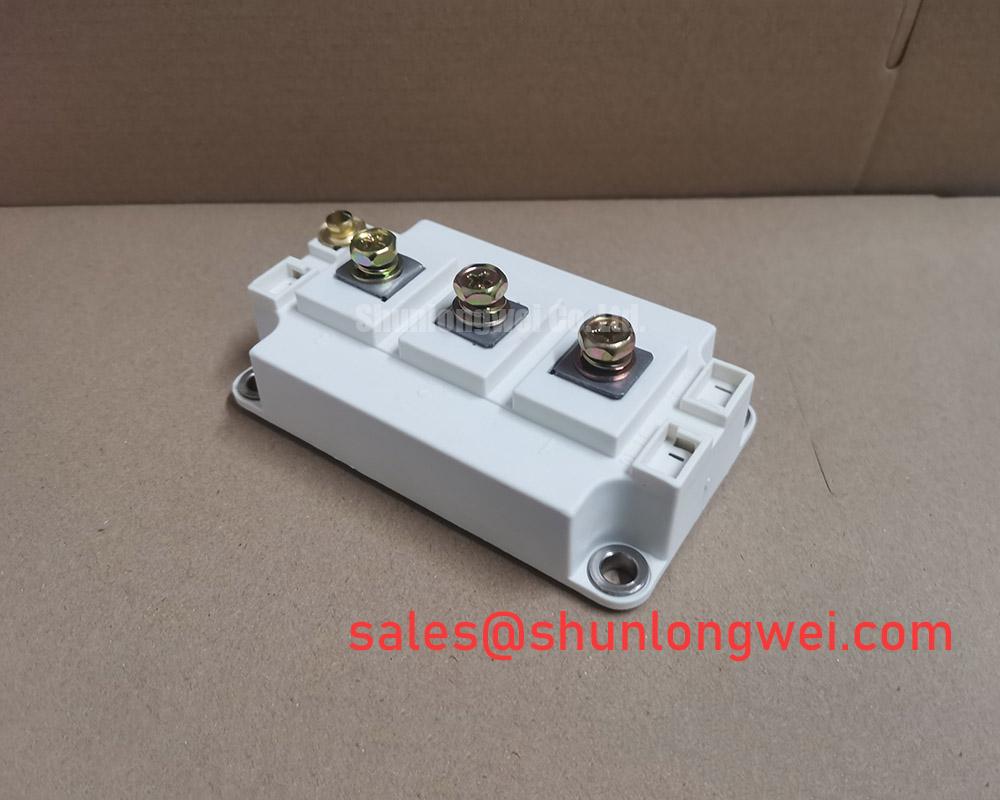

GTS450CL120T2VH | 1200V 450A Half-Bridge IGBT Module for High-Reliability Power Systems

An Engineering-Focused Overview of the GTS450CL120T2VH IGBT Module

The GTS450CL120T2VH is a 1200V half-bridge IGBT module engineered for exceptional thermal reliability in demanding high-power conversion systems. It integrates Trench Field Stop IGBT technology to deliver a combination of high performance and operational robustness. What is the primary benefit of its high junction temperature rating? Enhanced system reliability by providing a significant thermal safety margin. This module's electrical and thermal characteristics make it a strategic component for developing efficient and durable power electronics. Best fit for high-power industrial drives and renewable energy inverters where thermal robustness and long-term reliability are paramount design criteria.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the GTS450CL120T2VH are foundational to its performance in high-stress applications. The parameters below highlight the module's capacity for high-current operation, efficient switching, and superior thermal management, which are critical for system-level design and reliability.

| Parameter | Typical Value | Conditions |

|---|---|---|

| Collector-Emitter Voltage (Vces) | 1200 V | Tj = 25°C |

| Continuous Collector Current (Ic) | 450 A | Tc = 100°C |

| Collector-Emitter Saturation Voltage (Vce(sat)) | 2.1 V | Ic = 450A, Vge = 15V, Tj = 25°C |

| Maximum Junction Temperature (Tjmax) | 175 °C | - |

| Thermal Resistance, Junction-to-Case (Rth(j-c)) | 0.05 K/W | Per IGBT |

| Total Power Dissipation (Ptot) | 1875 W | Tc = 25°C |

Download the GTS450CL120T2VH datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Industrial Drives and Renewable Energy

The GTS450CL120T2VH is optimized for applications where power density, efficiency, and long-term reliability are non-negotiable. Its robust thermal architecture makes it particularly suitable for systems with high cyclic loads or those operating in challenging thermal environments.

- Industrial Motor Drives: In high-power Variable Frequency Drives (VFDs), frequent acceleration and deceleration cycles generate significant thermal stress. The module's high 175°C maximum junction temperature provides a crucial buffer, preventing over-temperature faults and enhancing the drive's service life, especially in demanding applications like cranes, extruders, and conveyor systems.

- Solar Inverters: For large-scale photovoltaic systems, maximizing energy harvest is key. The low Vce(sat) of the GTS450CL120T2VH reduces conduction losses, directly improving the DC/AC conversion efficiency. Its superior thermal performance ensures stable operation even during peak solar irradiance when ambient temperatures are high, contributing to greater overall system yield.

- Uninterruptible Power Supplies (UPS): The module's 450A current rating and ability to handle surge currents are critical for enterprise and industrial UPS systems, ensuring a reliable power backbone for critical infrastructure.

- Welding Equipment: High-frequency welding power supplies benefit from the module's fast switching characteristics and its ability to dissipate heat effectively under intense, repetitive load conditions.

While the GTS450CL120T2VH is ideal for 450A designs, for systems demanding even greater current handling, the CM600DX-24T provides a 600A capability within a similar voltage class.

Frequently Asked Questions (FAQ)

How does the 175°C Tjmax of the GTS450CL120T2VH translate to practical design advantages?

A 175°C rating provides a wider thermal operating margin. This allows engineers to design more compact cooling systems, increase the power density of the final product, or enhance reliability by operating the device further from its absolute maximum limit, which is critical in applications with unpredictable load profiles or high ambient temperatures.

What is the significance of the low 0.05 K/W thermal resistance (Rth(j-c)) for a system designer?

This value indicates highly efficient heat transfer from the silicon chip to the module's baseplate. A lower Thermal Resistance simplifies heatsink selection and the overall thermal management strategy. It directly results in a lower chip temperature for a given amount of power dissipation, which is a key factor in extending the module's operational lifespan and power cycling capability.

With a Vce(sat) of 2.1V, how does this module impact overall inverter efficiency?

The Collector-Emitter Saturation Voltage, or Vce(sat), can be thought of as the small voltage drop across the IGBT when it's fully on. Power lost as heat (conduction loss) is calculated as Vce(sat) multiplied by the current. A lower Vce(sat) like 2.1V at 450A directly reduces this power loss, leading to less waste heat and a higher overall energy conversion efficiency for the inverter.

What considerations are necessary for the gate drive circuit for this 450A module?

A module of this power level requires a robust Gate Drive circuit capable of supplying sufficient peak current to charge and discharge the IGBT's input capacitance quickly for efficient switching. It is crucial to ensure clean gate voltage levels (e.g., +15V/-15V) and minimize inductance in the gate drive loop to prevent parasitic turn-on and ringing, which can compromise performance and reliability.

Technical Deep Dive

The Engineering Synergy of Thermal Performance and Efficiency

The defining characteristic of the GTS450CL120T2VH is not a single parameter but the interplay between its thermal and electrical properties. The module's reliability is fundamentally anchored in its ability to manage heat, a challenge that grows exponentially with power density. The low thermal resistance (Rth(j-c)) of 0.05 K/W is the critical first step in this process.

Think of Rth(j-c) as the width of a drainpipe for heat. A low value represents a very wide pipe, allowing heat generated at the silicon junction to be evacuated swiftly to the case and attached heatsink. This efficiency in heat transfer is what prevents the junction temperature from spiking under heavy load. When this is paired with the high maximum junction temperature of 175°C, it creates an exceptionally large thermal buffer. This buffer is the engineering foundation for the module's high thermal cycling capability, enabling it to withstand the mechanical stresses induced by repeated temperature swings without degradation, a common failure point in lesser modules. This strategic design approach ensures predictable, long-term performance in the field.

Strategic Design Implications

Integrating the GTS450CL120T2VH is a strategic decision that prioritizes system longevity and performance under demanding thermal conditions. Its combination of a high temperature ceiling and efficient heat extraction path provides designers with the flexibility to push power density boundaries or to build in an extra margin of safety for applications where maintenance is difficult and reliability is paramount. This module represents a robust building block for next-generation power converters that are not only powerful and efficient but also engineered to endure. For further reading on selecting the right IGBT, explore our guide on the core trio of IGBT module selection.