The Gloved Hand Dilemma: A Common Industrial HMI Challenge

In any modern industrial setting—from a bustling CNC machine shop to a sterile pharmaceutical cleanroom or a frigid cold storage facility—the Human-Machine Interface (HMI) is the central point of control. Yet, a fundamental conflict often arises: the operators who need to interact with these systems are required to wear gloves for safety, hygiene, or environmental protection. This is where the slick, responsive touch experience we know from our smartphones often fails spectacularly.

An operator clad in thick, leather work gloves fumbling with a non-responsive screen isn’t just a moment of frustration; it’s a direct hit to productivity, a source of costly input errors, and a potential safety hazard. The core of this issue lies in the touchscreen technology itself. Not all “touch” is created equal. The technology that makes a consumer tablet feel magical can be the Achilles’ heel of an industrial control panel. Choosing the wrong type of touchscreen for a gloved environment can doom a project from the start, leading to operator workarounds, premature hardware failure, and a poor return on investment. This guide dissects the three primary industrial touchscreen technologies—Resistive, Projected Capacitive (PCAP), and Infrared (IR)—to provide a clear verdict on which is best suited for the demanding world of gloved operations.

Understanding the “Touch”: How Each Technology Works

To select the right tool for the job, an engineer or purchasing manager must first understand the fundamental principles behind each technology. The “best” choice depends entirely on how a screen registers a touch and whether a gloved finger can satisfy that mechanism.

Resistive Touch: The Pressure-Based Veteran

Resistive touchscreens are one of the most established and straightforward touch technologies. Imagine two flexible layers, each coated with a transparent conductive material (like Indium Tin Oxide) and separated by a tiny air gap. When you press on the screen’s surface, the top flexible layer deforms and makes physical contact with the bottom layer, closing an electrical circuit. The controller then calculates the precise X-Y coordinates of this contact point.

The key takeaway here is that resistive technology relies on pressure. It doesn’t matter what applies the pressure—a bare finger, a gloved finger, a stylus, the corner of a credit card—as long as it can press the layers together, the touch will register. This inherent flexibility is its greatest strength in industrial settings. While not as optically brilliant as newer technologies, models like the G104XCE-L01 often form the basis for reliable resistive HMI panels.

![Diagram illustrating the working principle of a resistive touchscreen]](https://www.slw-ele.com/wp-content/uploads/2025/06/svgviewer-png-output-1.png)

Projected Capacitive (PCAP): The Modern Standard’s Secret

Projected Capacitive (PCAP) is the technology used in virtually all modern smartphones and tablets. It works by projecting a grid-like electrostatic field through a glass top layer. A conductive object, such as a human finger, has natural capacitance that disrupts this field when it comes close. Sensors at the edge of the screen detect this change in capacitance and triangulate the location of the touch.

The critical word here is conductive. Most standard industrial gloves (leather, rubber, thick cotton) are electrical insulators. They prevent the operator’s finger from coupling with the screen’s electrostatic field, rendering the touch useless. While some specialized PCAP controllers offer enhanced sensitivity modes, and conductive-tipped gloves exist, these are often impractical workarounds in harsh environments. PCAP’s strength lies in its excellent optical clarity, durability (with a hard glass front), and true multi-touch capabilities (pinch-to-zoom), making it ideal for applications where gloved use is not a primary concern, such as in control rooms or for certain medical devices.

Infrared (IR) Touch: Breaking the Beam

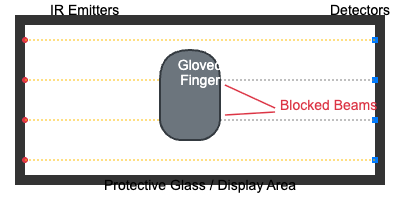

Infrared touch technology takes a completely different, non-contact approach. An IR touchscreen has a bezel or frame around the display that is embedded with a grid of infrared LEDs on two adjacent sides and photodetectors on the two opposite sides. This creates an invisible grid of IR light beams just above the surface of the glass.

When any opaque object—a bare finger, a stylus, or, most importantly, a thickly gloved finger—touches the screen, it physically blocks some of the horizontal and vertical light beams. The photodetectors instantly note the absence of these beams, and the controller calculates the X-Y coordinates of the interruption. Because it’s a purely optical system, the type of object, its material, and its thickness are irrelevant. This makes IR technology exceptionally robust for gloved use and highly resistant to surface contaminants that might confuse other technologies.

Protective Glass / Display Area IR Emitters Detectors GlovedFingerBlocked Beams

Head-to-Head: Resistive vs. PCAP vs. IR for Gloved Operation

Choosing the right technology requires a trade-off analysis. The following table compares these three technologies across the most critical parameters for industrial HMI selection, with a special focus on gloved operation.

| Feature | Resistive Touch | Projected Capacitive (PCAP) | Infrared (IR) Touch |

|---|---|---|---|

| Gloved Operation (Thick/Non-Conductive) | Excellent. Works with any glove type as it relies on pressure. | Poor. Requires bare fingers, a special stylus, or conductive gloves. | Excellent. Works with any opaque object, regardless of material or thickness. |

| Multi-Touch Capability | Limited (typically single-touch only). | Excellent (10+ points, supports pinch-to-zoom). | Good (typically supports 2-10 points). |

| Durability & Scratch Resistance | Moderate. The flexible top layer is susceptible to scratches and sharp objects. | Excellent. Can use chemically hardened glass (e.g., Gorilla Glass). | Excellent. The protective glass is not part of the touch system and can be very thick and rugged. |

| Contaminant Resistance | Good. The screen is sealed, but heavy grease or grit can damage the surface. | Excellent. A solid glass surface is easy to clean and seal (high IP ratings). Water can cause false touches. | Superior. Unaffected by non-opaque surface contaminants like water, oil, or dust. Heavy buildup on the bezel can be an issue. |

| Optical Clarity & Brightness | Fair to Good. The multiple layers and air gap reduce light transmission by ~20-25%. | Excellent. Light transmission can be >90%, resulting in a bright, clear image. | Excellent. No sensor layers over the LCD panel itself, allowing for maximum brightness. |

| Accuracy & Precision | Good. Suitable for button presses, but can suffer from drift over time requiring re-calibration. | Excellent. Highly accurate and stable, no calibration needed. | Good to Excellent. Very accurate, though parallax error can be a factor on very thick screens. |

| Relative Cost | Lowest. Mature technology. | Moderate. The most common technology today. | Highest. The cost increases with screen size due to the bezel components. |

Case Study: Upgrading a CNC Machining Center HMI

To put this theory into practice, consider a real-world scenario we encountered with a client in the metal fabrication industry.

- Problem: The client upgraded their fleet of CNC milling machines from legacy panels with membrane buttons to modern touchscreen HMIs. Their initial choice was a 12″ PCAP-based panel, valued for its sleek look and multi-touch capability. However, operators, who are required to wear thick, oil-resistant safety gloves, found the screens nearly impossible to use. This led to a documented 15% increase in data entry errors and an average of 5-7 minutes of lost production time per shift as operators removed gloves or struggled with repeated presses.

- Solution: After a consultation and analysis of their workflow, we recommended a switch to a ruggedized HMI built around an Infrared (IR) touch system on a robust LCD like the G150XTN06.B. The IR frame is inherently “zero-bezel” capable from the front, allowing it to be sealed into a console with a high NEMA/IP rating, protecting it from the coolant and metal dust prevalent in the environment. [Note to editor: Search for external link to “NEMA enclosure ratings explained”]

- Result: The impact was immediate and quantifiable. The IR screens registered every gloved touch with 100% reliability, even with a light sheen of coolant on the glass. Within the first quarter of deployment, operator-logged input errors fell by over 95% to pre-upgrade levels. The time savings from eliminating interaction struggles contributed to a measurable 5% increase in Overall Equipment Effectiveness (OEE), providing a clear and rapid return on the investment in the more suitable technology.

Your Selection Checklist: Choosing the Right Gloved-Use Touchscreen

Before you specify a touchscreen like the LQ121S1LG84 or the AA104SH12 for your next project, run through this practical checklist to ensure you’re matching the technology to the application’s true needs.

- Assess the Glove Type: This is the most critical question. Are operators using thin latex/nitrile gloves, standard work gloves, thick leather gauntlets, or multi-layered safety gloves? If the gloves are anything other than thin and disposable, PCAP is likely the wrong choice.

- Evaluate the Operating Environment: Will the screen be exposed to liquids (water, oil, chemicals), dust, dirt, or extreme temperatures? An IR screen’s immunity to surface liquids gives it a huge advantage over PCAP (which can suffer from false touches) and Resistive (whose surface can be damaged by harsh cleaning).

- Analyze the User Interface (UI): Does the control software require multi-touch gestures like pinch-to-zoom for schematics or maps? If so, PCAP (for bare hands) or multi-touch IR are your only options. If the UI is based on simple button presses, sliders, and data entry, single-touch Resistive or IR is perfectly sufficient.

- Balance Performance and Total Cost of Ownership (TCO): Resistive is the cheapest upfront. However, if its softer surface wears out and requires replacement in two years, is it truly cheaper than a more durable IR or PCAP screen that lasts for ten? Consider the cost of downtime and operator inefficiency, not just the component price.

- Don’t Forget Durability and Sealing: How much physical abuse will the screen take? IR and PCAP technologies allow for a very thick, durable, and non-functional piece of protective glass on top. This makes it easier to design a fully sealed, washdown-rated unit (e.g., IP65 or higher). A wide selection of displays, such as the industrial LCD modules, provides the foundation for these rugged designs.

Final Verdict: Which Technology Wins for Gloved Hands?

For industrial environments where operators must wear gloves, the choice becomes remarkably clear. While each technology has its place, one stands out for reliability and performance under these specific conditions.

- Resistive Touch: Remains a viable, budget-friendly champion for simple, single-touch applications where cost is the primary driver and extreme durability is not required. It’s the go-to for legacy system replacements or when universal input compatibility is needed on a tight budget.

- Projected Capacitive (PCAP): Despite being the modern consumer standard, PCAP is fundamentally the wrong choice for any application requiring the use of standard, non-conductive industrial gloves. It excels in clean environments where operators have bare hands or can use a dedicated stylus.

- Infrared (IR) Touch: This is the definitive winner for gloved operations. Its optical-based detection is indifferent to glove material or thickness, offers excellent optical clarity, and enables highly durable and sealed HMI designs. While it carries a higher initial cost, the gains in productivity, reduction in errors, and superior reliability deliver a lower Total Cost of Ownership in demanding industrial settings.

Navigating the nuances of industrial display technology is critical to the success of your equipment design. If you’re challenged with specifying a touchscreen for a unique gloved-operation environment or need help selecting a component that balances performance with cost, our expert team is here to assist. Contact our application engineers for technical support and let us help you find the perfect solution from our extensive portfolio of industrial displays.