Digital Signage & Outdoor Advertising: High Brightness, Waterproofing, and Smart Temperature Control for 24/7 Uptime

The Unseen Battle: Why Most Outdoor Digital Displays Fail Prematurely

In the world of advertising, capturing attention is everything. Outdoor digital signage promises dynamic, high-impact messaging that traditional billboards can’t match. From bustling city squares to highways and transit hubs, these screens are powerful tools for communication. However, the reality of deploying and maintaining them is a harsh lesson in engineering. The biggest challenge isn’t the content; it’s the environment. An outdoor display wages a constant, unseen battle against sunlight, rain, humidity, dust, and extreme temperatures.

Many businesses invest heavily in outdoor digital displays only to see them fail prematurely. Common failure points are often underestimated during the procurement process:

- Screen Washout: On a bright, sunny day, a standard display becomes an unreadable, reflective surface. The message is lost, and the investment is wasted.

- Water and Humidity Damage: Rain, snow, and even high ambient humidity can lead to condensation inside the unit. This moisture can short-circuit sensitive electronics, corrode connectors, and cause permanent damage to the LCD panel itself.

- Thermal Failure: Screens can overheat under direct sunlight, causing dark blotches (a defect known as Mura) or complete shutdown. Inversely, in cold climates, components can freeze, leading to sluggish performance or an inability to power on.

These failures result in more than just a blank screen. They lead to lost advertising revenue, damage to brand reputation, and costly, often difficult, on-site maintenance. Achieving true 24/7 uptime requires a display that isn’t just placed outdoors but is *engineered* for the outdoors. This involves a triad of critical technologies: high brightness, robust waterproofing, and intelligent thermal management.

Mastering Visibility: The Critical Role of High Brightness and Optical Engineering

The primary function of any display is to be seen. For an outdoor screen, this means overcoming the brightest object in our solar system: the sun. Direct sunlight can completely wash out a conventional display, rendering it useless. This is where the concept of “nits,” a measure of luminance, becomes critical.

An average indoor monitor or TV might have a brightness of 250-400 nits. For a shaded outdoor area, you might need at least 1,000 nits. For direct sunlight readability, the standard is 2,500 nits or higher. This level of brightness ensures that the content remains vibrant and clear, even on the sunniest days. However, achieving superior visibility isn’t just about a powerful backlight. It’s about smart optical engineering.

- Anti-Reflective (AR) and Anti-Glare (AG) Coatings: The outer glass of the display is the first line of defense against ambient light. An AR coating uses thin film layers to reduce the amount of light that reflects off the surface, while an AG treatment uses a slightly roughened surface to diffuse reflections, preventing mirror-like glare.

- Optical Bonding: This is a game-changing technology for outdoor displays. In a standard screen, there is a tiny air gap between the LCD panel and the protective outer glass. This air gap causes internal reflections that reduce contrast and readability. Optical bonding fills this gap with a transparent, UV-resistant resin. This process eliminates the internal reflections, dramatically increasing contrast ratio and sunlight legibility while also making the screen more physically robust and preventing condensation from forming internally.

- Automatic Brightness Control: Running a 3,000-nit display at full power 24/7 is not only inefficient but also drastically shortens the backlight’s lifespan. An integrated ambient light sensor allows the display to intelligently adjust its brightness. It can output maximum nits in direct sun, dim down on cloudy days or at night, saving significant energy and reducing thermal load.

Fortifying the Fortress: IP Ratings and Advanced Waterproofing Techniques

Water and electronics do not mix. For an outdoor display, protection from moisture is non-negotiable. This is where the Ingress Protection (IP) rating system provides a standardized measure of a product’s sealing effectiveness.

An IP rating consists of two digits. The first (0-6) rates protection against solid objects (like dust), and the second (0-8) rates protection against liquids. For outdoor signage, you should look for a minimum of IP65.

- IP65: Dust-tight and protected against water jets from any direction. This is suitable for most general outdoor applications.

- IP66: Dust-tight and protected against powerful water jets. Ideal for areas with high-pressure cleaning or exposure to severe storms.

- IP67: Dust-tight and protected against temporary immersion in water.

Achieving a high IP rating requires meticulous design and high-quality materials. It’s not as simple as putting a box around a screen. Key engineering considerations include precision-cut gaskets made from durable materials like silicone, sealed and waterproof connectors for all I/O, and secure cable glands. Furthermore, a crucial element for long-term reliability is the use of conformal coating on the internal printed circuit boards (PCBs). This is a thin, protective chemical coating that shields the electronic components from moisture, dust, and corrosion, providing a vital layer of defense even if ambient humidity is high.

Case Study: Transit Hub Display

Problem: A metropolitan transit authority installed digital signage at outdoor bus shelters. The initial displays, which had a low IP rating, suffered frequent failures during the rainy season due to water ingress and internal condensation, leading to high repair costs and unreliable schedule information for passengers.

Solution: The failing units were replaced with fully sealed, IP66-rated industrial displays. These units featured sealed aluminum enclosures, waterproof connectors, and conformal-coated internal electronics. They also followed strict module mounting guidelines to ensure a perfect seal.

Result: The new displays achieved over 99.8% uptime through the following year, including several severe storms. Maintenance calls related to weather damage dropped to zero, improving system reliability and public trust.

The Thermal Challenge: Intelligent Temperature Control for Extreme Conditions

Temperature is the silent killer of outdoor electronics. The operational challenge is twofold: removing heat in hot conditions and staying warm enough to function in the cold. A display in direct sunlight can see its internal temperature soar far above the ambient air temperature, while a winter night can drop it below freezing.

Effective thermal management is not an optional feature; it is core to the display’s survival and performance. A system with an operating temperature range of -20°C to +50°C (-4°F to 122°F) is a good baseline for most climates.

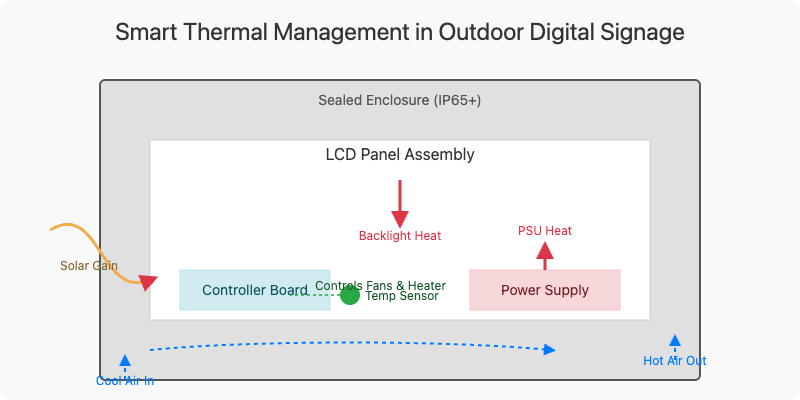

This is accomplished through a combination of passive and active solutions, governed by a “smart” control system:

- Passive Cooling: This includes using the chassis of the display as a giant heatsink, often made from high-thermal-conductivity materials like aluminum, to dissipate heat naturally.

- Active Cooling: For high-brightness displays or hot climates, passive cooling isn’t enough. An active system uses industrial-grade, high-reliability fans to force airflow through the unit, or in extreme cases, integrated heat exchangers or even small air conditioning units.

- Smart Temperature Control: This is the brain of the operation. Multiple sensors inside the unit constantly monitor the temperature at critical points (e.g., near the LCD panel, the power supply, and the controller board). This data is fed to a microcontroller that intelligently manages the thermal systems. If the internal temperature drops near freezing, it can activate small internal heating elements to keep the liquid crystals in the LCD panel responsive. If the temperature exceeds a set threshold, it activates the cooling fans at variable speeds to efficiently remove heat without wasting energy.

This intelligent system prevents the screen from overheating and blacking out on a hot day and ensures it powers on and performs correctly on a cold morning, which is essential for true 24/7 power module reliability.

Selecting the Right Industrial LCD Panel: A Practical Checklist for Engineers and Buyers

When sourcing a display for an outdoor project, you must look beyond the spec sheet of a consumer TV. Industrial-grade panels are built with more robust components and wider operating tolerances. Use this checklist to guide your selection process.

| Feature | Specification to Look For | Why It Matters |

|---|---|---|

| Brightness (Luminance) | Minimum 2,500 nits for direct sun | Ensures content is visible and legible against bright ambient light. |

| IP Rating | IP65 or higher | Guarantees protection against dust and water ingress, crucial for outdoor survival. |

| Operating Temperature | Wide range (e.g., -20°C to 50°C) | Ensures reliable operation in both hot summers and cold winters. |

| Optical Bonding | Yes (Resin-filled) | Increases contrast, improves readability, and adds physical durability. |

| Cover Glass | Anti-Reflective (AR), thermally-toughened glass | Reduces glare and withstands physical impacts and thermal stress. |

| Thermal Management | Smart Temperature Control System | Actively heats and cools the unit to stay within optimal operating range, preventing failures. |

| Backlight Lifetime | 50,000+ hours (MTBF) | Indicates long-term reliability and lower total cost of ownership. A robust panel like the G150XNE-L01 is designed for longevity. |

| Certifications | CE, FCC, UL | Verifies the product has been tested to meet safety and performance standards. |

Conclusion: Building a Resilient Digital Signage Network for Uninterrupted Impact

An outdoor digital display is a complex system that must perform flawlessly in an unforgiving environment. Success is not a matter of chance, but a result of deliberate engineering choices. The three pillars—high brightness with optical bonding, robust IP-rated waterproofing, and intelligent thermal management—are the foundation of any reliable outdoor screen.

By prioritizing these features during selection, engineers and project managers can move beyond the cycle of frequent failures and high maintenance costs. Investing in a purpose-built industrial outdoor display from the outset reduces the total cost of ownership and ensures your message is delivered with maximum impact, 24 hours a day, 7 days a week. For your next outdoor advertising project, don’t compromise on reliability. Explore our range of industrial-grade LCD displays, such as the high-performance G121AGE-L03, designed to withstand the elements and deliver your message 24/7. Contact our engineering team for a consultation on a solution tailored to your specific environmental challenges.