Content last revised on January 27, 2026

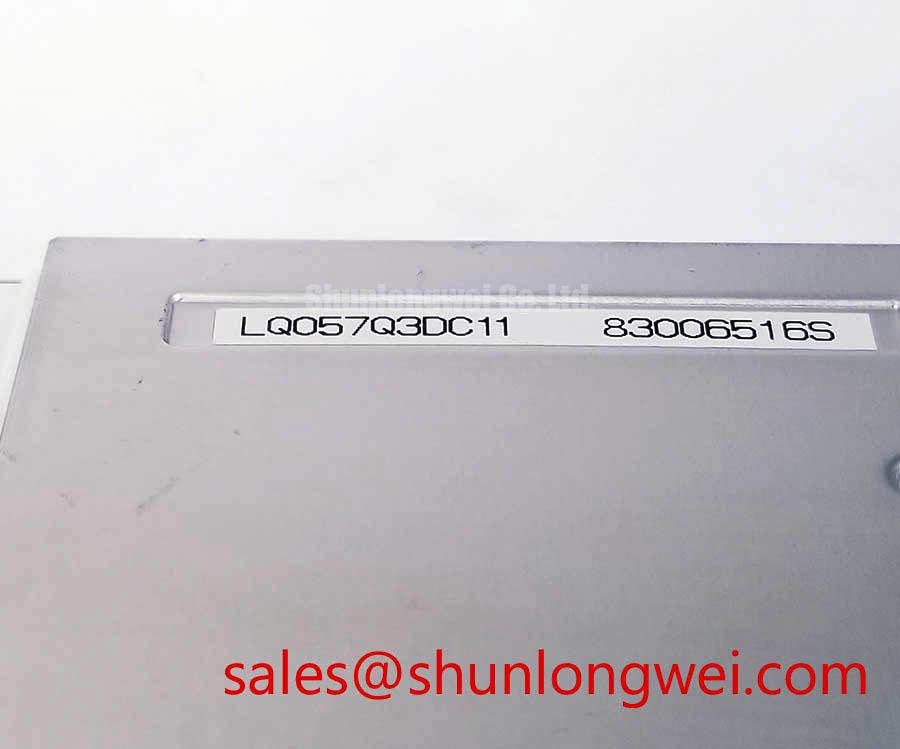

Sharp LQ057Q3DC11: A 5.7" QVGA Industrial LCD for Extreme Temperatures and Visual Clarity

Executive Summary: Key Engineering Features

The Sharp LQ057Q3DC11 is a 5.7-inch TFT-LCD engineered to deliver unwavering performance in thermally challenging industrial and outdoor applications. It combines a robust build with excellent optical characteristics to ensure data is always readable and reliable. At its core, the LQ057Q3DC11 provides an exceptional solution for designers of ruggedized equipment. Key specifications include: 320x240 QVGA | 400 cd/m² Brightness | -30°C to +80°C Operating Range. This module offers two primary engineering benefits: exceptional environmental resilience and clear readability in high ambient light. Its extremely wide operating temperature range ensures consistent performance without auxiliary thermal management, directly addressing a key challenge for outdoor and unconditioned industrial deployments. Best fit for industrial control panels and mobile instrumentation requiring proven reliability across a wide thermal spectrum.

Application Scenarios & Value

System-Level Benefits in Demanding Industrial Environments

The LQ057Q3DC11 is engineered specifically for applications where environmental conditions are a primary design constraint. Its value extends beyond the component level, directly impacting system reliability and total cost of ownership. What defines the LQ057Q3DC11's core advantage? Its ability to operate reliably across a -30°C to +80°C temperature range.

Consider the design of a Human-Machine Interface (HMI) for a cold storage facility forklift or an outdoor payment kiosk. These systems face sub-zero temperatures and potential solar loading. The LQ057Q3DC11's wide thermal range eliminates the need for dedicated heating and cooling components within the sealed NEMA enclosure. This simplification reduces the bill of materials (BOM), lowers power consumption, and removes potential points of failure, leading to a more robust and cost-effective final product. Furthermore, its 400 cd/m² brightness and anti-glare surface ensure that critical operational data remains legible for operators, enhancing both safety and efficiency in challenging visual environments.

For systems that demand even higher brightness for full-sunlight conditions, the related AA057VF12 provides an alternative optical profile to evaluate.

Key Parameter Overview

Decoding the Specifications for Environmental Resilience

The performance of the Sharp LQ057Q3DC11 is defined by a set of specifications tailored for industrial reliability. The parameters below highlight its capacity to deliver stable visual performance under demanding operational conditions. Understanding these values is key to integrating the display effectively.

| Optical Characteristics | |

|---|---|

| Screen Size | 5.7 inch |

| Resolution | 320(RGB) x 240 (QVGA) |

| Luminance | 400 cd/m² (Typ.) |

| Contrast Ratio | 250:1 (Typ.) (Transmissive) |

| Viewing Angle | 60/60/40/60 (Typ.)(CR≥10) (L/R/U/D) |

| Surface Treatment | Anti-glare |

| Mechanical & Environmental Ratings | |

| Module Dimensions | 144(W) x 104.6(H) x 13(D) mm |

| Active Area | 115.2(W) x 86.4(H) mm |

| Operating Temperature | -30 ~ 80 °C |

| Storage Temperature | -40 ~ 85 °C |

| Electrical Interface & Backlight | |

| Interface Type | Parallel RGB (1 ch, 6-bit), 33 pins |

| Backlight System | CCFL |

Engineering FAQs on Integration and Reliability

Clarifying Key Design Considerations

How does the -30°C to +80°C operating temperature range impact system design and total cost of ownership?

This wide range allows the display to be deployed in unconditioned environments without requiring external heaters or cooling fans. This directly reduces the system's mechanical complexity, power budget, and potential points of failure, ultimately lowering the total cost of ownership and improving the reliability of the end device. It provides a significant advantage over displays with a standard 0-50°C range. For a deeper analysis of this topic, see this guide on industrial vs. consumer displays.

What is the practical benefit of the Anti-Glare (AG) surface treatment in an industrial setting?

How does its surface treatment help? The anti-glare surface minimizes reflections, ensuring clear readability in bright conditions. In a factory or outdoor setting with multiple light sources, reflections on a glossy screen can obscure critical data, leading to operator error or eye strain. The AG treatment diffuses ambient light, reducing specular reflections and maintaining high contrast for the displayed information, which is a vital feature explored in resources like the engineer's guide to sunlight readable HMIs.

Is the 18-bit Parallel RGB interface suitable for modern embedded systems?

Yes, the parallel RGB interface is a highly stable and widely supported standard, particularly for industrial embedded systems. It provides a direct, low-latency connection to many microcontrollers and processors, simplifying driver development and ensuring robust data transmission. While newer interfaces exist, the maturity of parallel RGB offers proven reliability and straightforward implementation, making it an excellent choice for control-focused applications where dependability is paramount.

Application Vignette: System Design

Designing a Robust Agricultural HMI with the LQ057Q3DC11

An agricultural harvester cabin presents a formidable challenge for electronic displays: extreme temperature swings from pre-dawn cold to midday solar load, constant high-amplitude vibration, and intensely bright, direct sunlight. The engineering goal is to create an HMI that provides clear, reliable data from the vehicle's Programmable Logic Controller (PLC) under all conditions.

The LQ057Q3DC11 is an ideal candidate for this scenario. Its -30°C to +80°C operating specification inherently manages the thermal extremes without requiring a complex thermal subsystem. The 400 cd/m² luminance, coupled with the anti-glare screen, cuts through the reflections common in a glass cabin, ensuring the operator can always read vital statistics. The contrast ratio is also a key factor here; think of it as the difference between the blackest ink and the whitest paper. A strong ratio ensures that graphics and numbers "pop," reducing the chance of an operator misreading critical data during a fast-paced harvesting operation. The result is a simplified, highly reliable HMI that enhances operator efficiency and equipment uptime.

For detailed schematics and application notes to accelerate your design cycle, consulting the official product datasheet from a trusted source like Sharp is a critical next step.