Content last revised on January 31, 2026

PS21964-4S Intelligent Power Module: Engineering Review

System Integration & Design Simplification in Low-Power Motor Drives

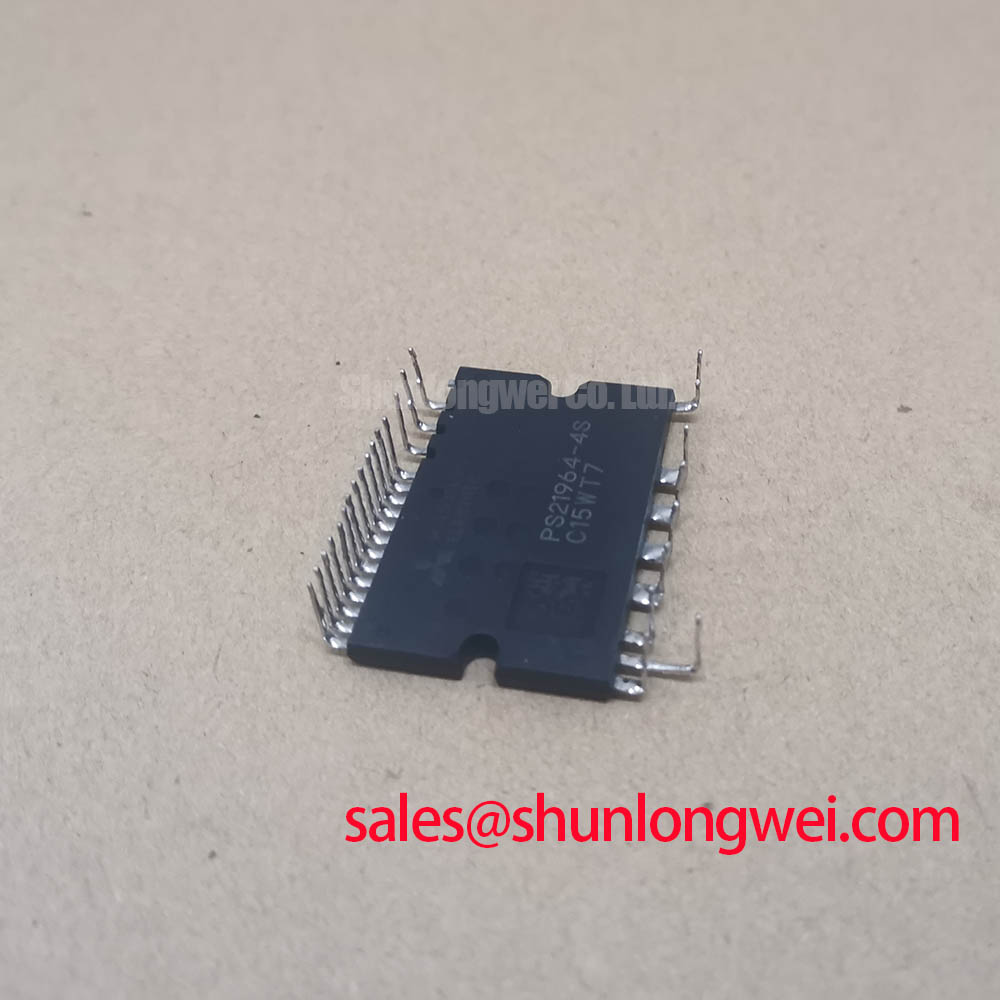

The Mitsubishi PS21964-4S is a 5th generation DIP (Dual In-line Package) Intelligent Power Module (IPM) designed for compact, low-power motor control applications. It delivers a fully integrated three-phase inverter solution that simplifies the power stage design by combining gate drivers, protection circuits, and low-loss IGBTs in a single component. With core specifications of 600V | 15A, this module provides integrated undervoltage (UV) and short-circuit (SC) protection, enabling robust and reliable system operation. Its high level of integration directly addresses the engineering challenge of minimizing PCB footprint and reducing design cycle time for variable speed drives. For low-power AC100-200V inverter drives where space and component count are critical design constraints, the PS21964-4S offers a validated and efficient power stage solution.

Key Parameter Overview

Decoding the Specs for Simplified System Integration

The parameters of the PS21964-4S are tailored for ease of use and reliability in motor control systems. The integrated control ICs and bootstrap diodes for the gate drive power supply significantly reduce the need for external components, streamlining the overall circuit design. This functional integration is a key enabler for designers aiming to accelerate time-to-market.

| Parameter | Value | Conditions |

|---|---|---|

| Inverter Part | ||

| Collector-Emitter Voltage (Vces) | 600V | |

| Collector Current (Ic) | 15A | Tc = 25°C |

| Collector-Emitter Saturation Voltage (Vce(sat)) | Typ. 1.7V / Max. 2.2V | Ic = 15A, Tj = 125°C |

| Control Part | ||

| Control Supply Voltage (Vd) | 13.5V - 16.5V | Applied between VP1-VNC, VN1-VNC |

| Control Input Threshold Voltage (Vth(on)) | Typ. 2.8V | Ic = 15A, Vcc=300V, Tj=25°C |

| Protection | ||

| Short-Circuit Protection Trip Level (SC) | Typ. 31A | Vd = 15V, Tj = 125°C |

| Control Supply UV Trip Level (UVt) | Typ. 11.2V | Tj = 25°C |

| General | ||

| Isolation Voltage (Viso) | 1500 Vrms | 60Hz, Sinusoidal, 1 minute |

| Maximum Junction Temperature (Tj max) | 150°C | Recommended average Tj ≤ 125°C |

Download the PS21964-4S datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Compact Motor Control

The PS21964-4S is engineered specifically for AC100V~200V inverter drives powering small motors. Its primary value lies in its ability to simplify the design process for applications where board space is at a premium and reliability is essential. Consider the design of a modern, energy-efficient home appliance like a refrigerator or an air conditioner compressor drive. The engineering challenge is to fit a capable and protected Variable Frequency Drive (VFD) into a very confined space. The PS21964-4S directly solves this by consolidating the three-phase bridge, the high-voltage level-shifting gate drivers for the upper arms, and the protection logic (short-circuit for lower arms, undervoltage for control supply) into a single DIP package. This integration eliminates numerous discrete components and the complex PCB layout they would require. The result is a smaller, more reliable, and faster-to-develop motor drive system. For applications demanding lower current, the related PS21961-4 provides a 5A alternative within the same family, allowing for scaled solutions.

Frequently Asked Questions (FAQ)

How does the integrated bootstrap circuit benefit my design?

The built-in bootstrap diodes and resistors for the high-side gate drive supply eliminate the need for an isolated power supply for the upper IGBTs. This reduces component count, cost, and PCB area, simplifying the power supply architecture of the entire system.

What is the function of the fault output (Fo) pin?

The Fo pin provides a clear, logic-level signal to the system's microcontroller in the event of a fault condition, such as a short-circuit in a lower-leg IGBT or an undervoltage condition on the control supply. This enables the system to safely shut down and prevents catastrophic failure, enhancing overall system robustness.

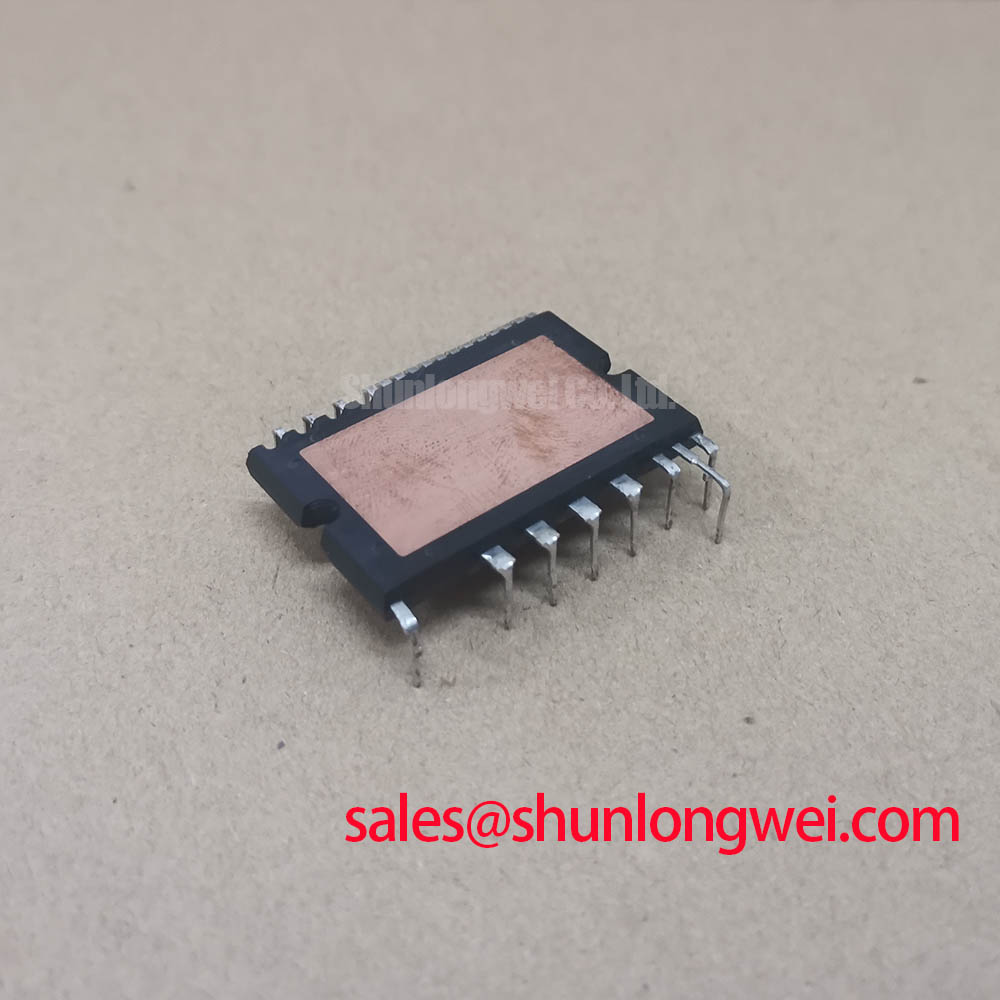

What are the key thermal management considerations for the PS21964-4S?

While the module integrates the power stage, effective heat dissipation is crucial. The datasheet specifies that a thermally conductive grease should be applied between the module and the heatsink. The thermal resistance is directly influenced by this interface, making proper mounting and heatsink selection critical to keeping the average junction temperature below the recommended 125°C for long-term reliability.

Is the input logic of the PS21964-4S compatible with standard microcontrollers?

Yes, the module features a 3V/5V compatible input interface, allowing for direct connection to the I/O pins of most standard CPUs or microcontrollers. This direct interface capability further reduces the need for external signal conditioning components, simplifying the control section of the design.

Industry Insights & Strategic Advantage

Meeting Demands for Miniaturization and Reliability

The trajectory of modern power electronics, particularly in appliance and light industrial automation, is defined by two key trends: miniaturization and increased reliability. The Mitsubishi PS21964-4S directly addresses these market drivers. As energy efficiency standards become more stringent, even small motors are migrating to inverter-based controls. An IPM (Intelligent Power Module) like this one provides a significant strategic advantage over discrete solutions. By integrating protection features and optimized gate drivers, it inherently reduces the risk of common failure modes associated with improper gate drive design or external interference. This pre-validated subsystem approach allows engineering teams to focus on higher-level control algorithms and system features, rather than the complexities of power stage design, ultimately leading to a more reliable end product with a faster time-to-market.

Strategic Outlook

For engineering teams developing next-generation compact motor drives, the adoption of an integrated power module like the PS21964-4S is a strategic decision that balances performance, footprint, and design velocity. By leveraging its built-in intelligence and protection, designers can deliver more robust and compact solutions that meet the evolving demands of the market for energy efficiency and long-term reliability.