Content last revised on January 31, 2026

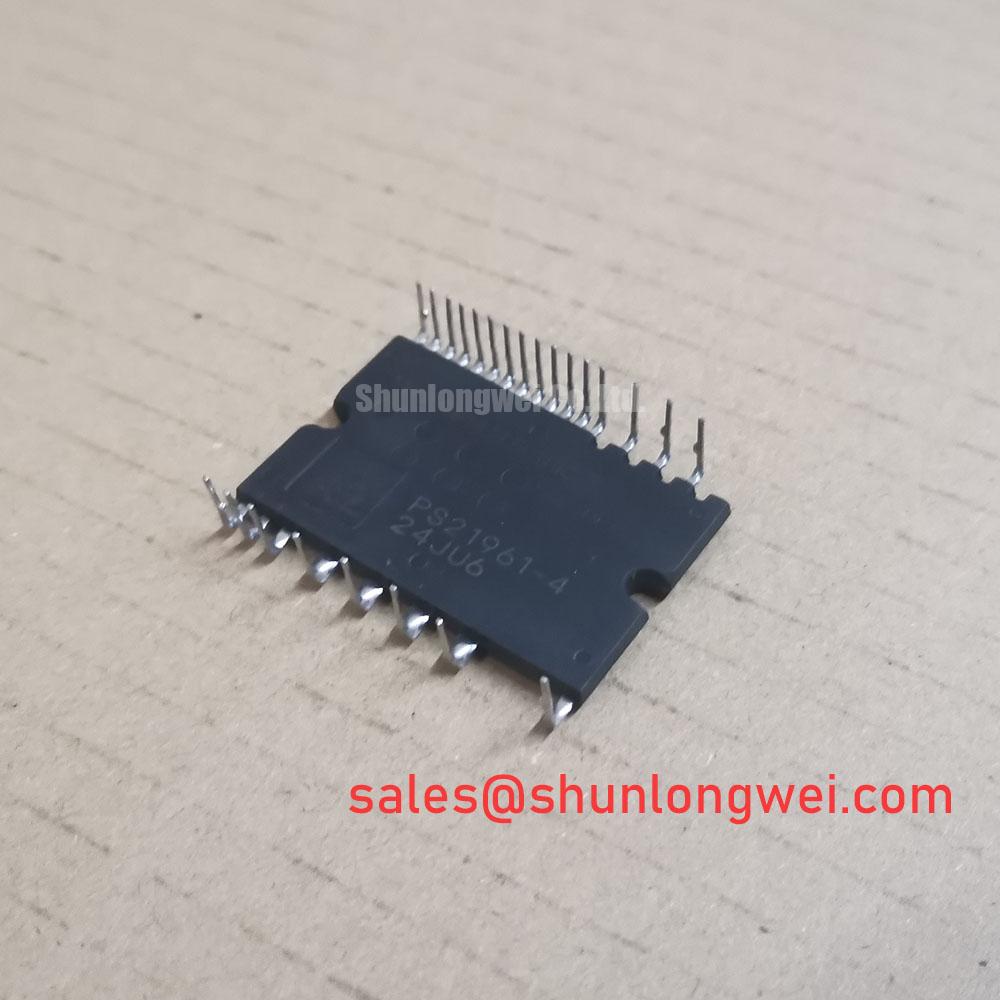

PS21961-4: Technical Review of a 600V, 5A DIP-IPM for High-Efficiency Motor Drives

An Engineer's Overview of the Mitsubishi PS21961-4 Intelligent Power Module

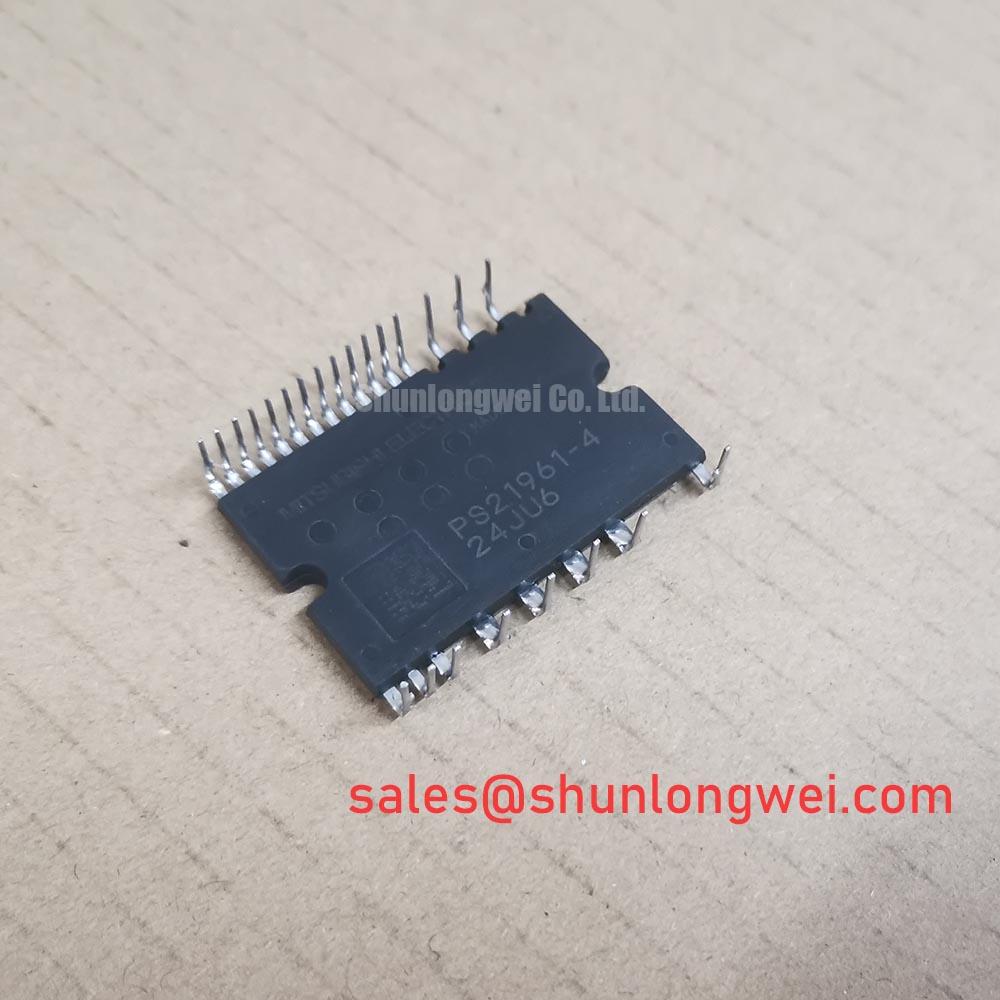

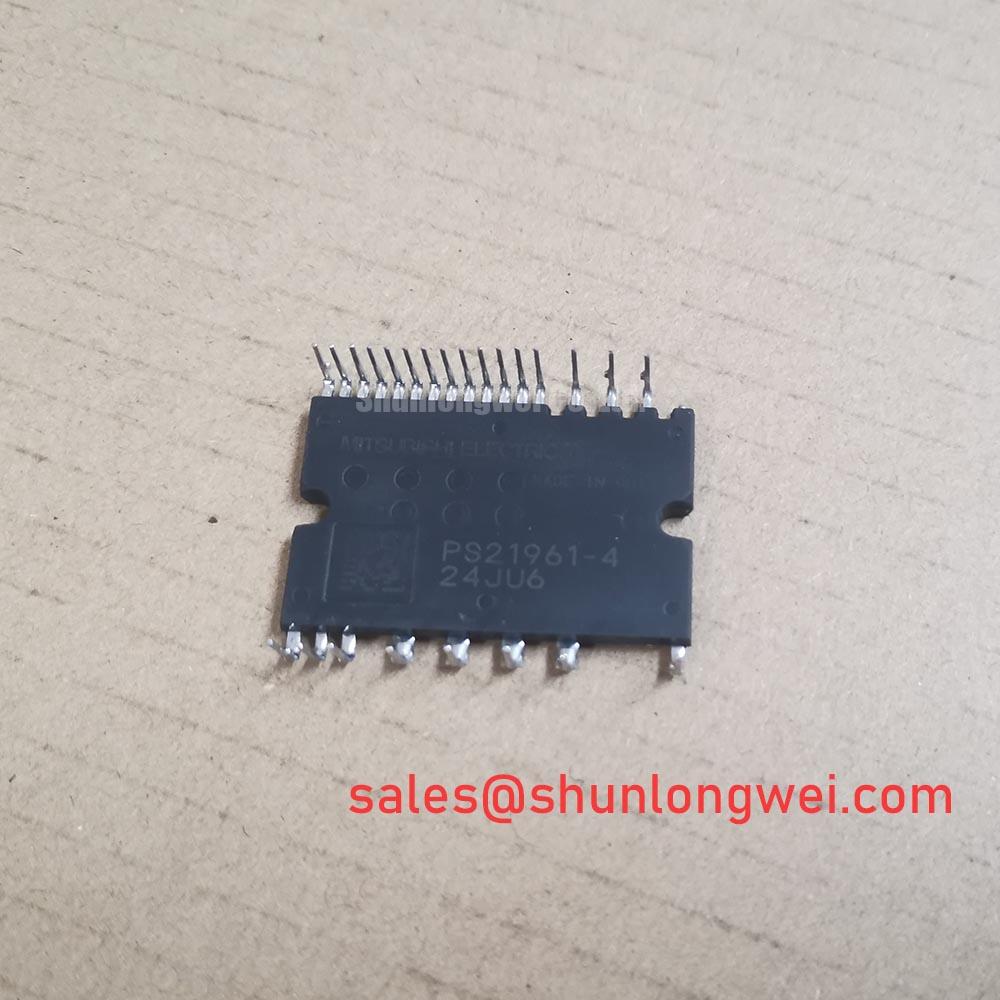

The PS21961-4 DIP-IPM streamlines low-power motor drive design by combining a low-loss 600V inverter with comprehensive, integrated protection features. This intelligent power module is defined by its core specifications: 600V | 5A | VCE(sat) 1.4V (typ). The primary engineering benefits are a drastically simplified PCB layout and fundamentally enhanced system reliability. This integration simplifies design by incorporating gate drivers and bootstrap circuits, which allows for a direct connection to a microcontroller and operation from a single control power supply. For space-constrained motor drives under 400W that demand high efficiency and robust protection, the PS21961-4 is an optimal integrated solution.

Application Scenarios & Value

System-Level Benefits in Compact Motor Control

The PS21961-4 is engineered to meet the stringent demands of low-power motion control systems where both efficiency and physical footprint are critical design constraints. Its primary application is in the inverters for small motors, particularly in home appliances and light industrial equipment. What is the main advantage of an integrated module in these designs? It significantly accelerates time-to-market by reducing the complexity of the power stage.

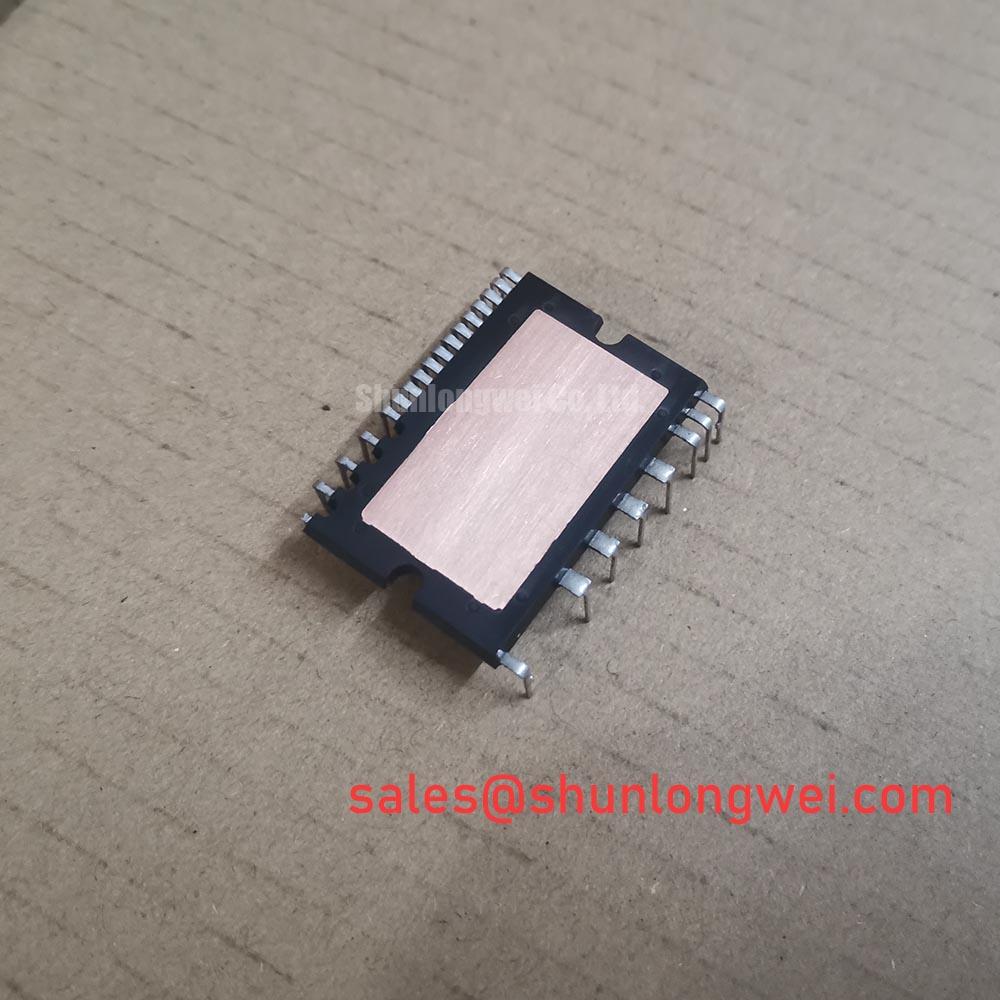

Consider the design of a modern, energy-efficient washing machine or a residential air conditioner fan. The engineer's challenge is to implement a quiet, reliable Variable Frequency Drive (VFD) within a compact, cost-sensitive chassis. The PS21961-4 directly addresses this. Its low collector-emitter saturation voltage (VCE(sat)) of 1.4V (typical) minimizes conduction losses. Think of VCE(sat) as the friction in the system; lower friction means less energy is wasted as heat. This superior efficiency reduces the thermal load, often allowing for a smaller heatsink or even heatsink-less operation in certain duty cycles, directly contributing to a smaller and more cost-effective final product. This high degree of integration makes it a cornerstone component for driving advanced motor types like Brushless DC (BLDC) motors and Permanent Magnet Synchronous Motors (PMSM).

For systems that require a higher current rating but a similar level of integration, the PS21964-4S provides a 15A alternative. Alternatively, for designs with different packaging or control requirements, the PS21564-P offers another option within the DIP-IPM family.

Key Parameter Overview

Decoding the Specs for High-Efficiency Inverter Design

The performance of the PS21961-4 is defined by a set of electrical and thermal characteristics that are crucial for system design and reliability. The following parameters are extracted from the official datasheet to support your engineering evaluation.

| Key Technical Specifications of the PS21961-4 | |

|---|---|

| Parameter Category | Specification & Conditions |

| Absolute Maximum Ratings |

|

| Inverter Part |

|

| Control Part |

|

| Protection Features |

|

Download the PS21961-4 datasheet for detailed specifications and performance curves.

Technical Deep Dive

Inside the Integrated Drive and Protection Architecture

A key differentiator of the PS21961-4 is the sophisticated system-on-a-chip (SoC) approach within its package. This module goes beyond simply co-packaging IGBTs. It integrates the essential circuits that an engineer would otherwise have to design, test, and validate externally. This includes optimized high-side and low-side gate drivers, level-shifting circuitry, and a complete bootstrap power supply for the high-side drivers, consisting of both diodes and current-limiting resistors. The benefit is a dramatic reduction in external component count and susceptibility to noise, which is critical when implementing fast-switching algorithms like Space Vector Modulation (SVM).

The integrated protection architecture acts as a robust safety net for the entire motor drive system. What is the primary benefit of its integrated protection? Enhanced long-term reliability by preventing catastrophic failure modes. The module provides three core protections:

- Short-Circuit (SC) Protection: By monitoring the voltage drop across an external low-side shunt resistor, the module can detect a dangerous overcurrent condition and safely shut down all six IGBTs, sending a fault signal back to the host microcontroller.

- Over-Temperature (OT) Protection: An on-chip temperature sensor directly monitors the LVIC (Low-Voltage IC) temperature. If it exceeds a safe threshold, the module initiates a shutdown to prevent thermal damage.

- Under-Voltage (UV) Lockout: This circuit ensures the control supply voltage is sufficient for proper IGBT gate drive operation. It prevents the IGBTs from operating in their linear region, a condition that can lead to high power dissipation and rapid failure.

These integrated functions operate like an intelligent, self-contained safety manager for the power stage. This built-in resilience simplifies meeting safety standards like IEC 60730 for household appliances and is a core part of the value proposition detailed in guides on IPM versus discrete IGBT design.

Frequently Asked Questions

Engineering Inquiries on the PS21961-4 IPM

How does the integrated bootstrap circuit in the PS21961-4 simplify the power supply design?

The integrated bootstrap circuit, including diodes and resistors, allows the high-side gate drivers to be powered from the main 15V control supply without requiring separate, isolated power sources. This eliminates the need for three independent floating power supplies, significantly reducing PCB complexity, component count, and overall system cost.

What is the role of the VCE(sat) of 1.4V in thermal management for appliance motor drives?

A lower VCE(sat) directly translates to lower power dissipated as heat during the on-state (conduction loss). In a thermally constrained application like a sealed appliance motor, the 1.4V VCE(sat) means less heat needs to be removed. This allows engineers to use a smaller, less expensive heatsink or, in some low-duty-cycle cases, to utilize PCB copper planes for cooling, saving critical space and cost.

For further information on selecting the right power module, please contact our technical support team to discuss your application's specific requirements.