Content last revised on November 20, 2025

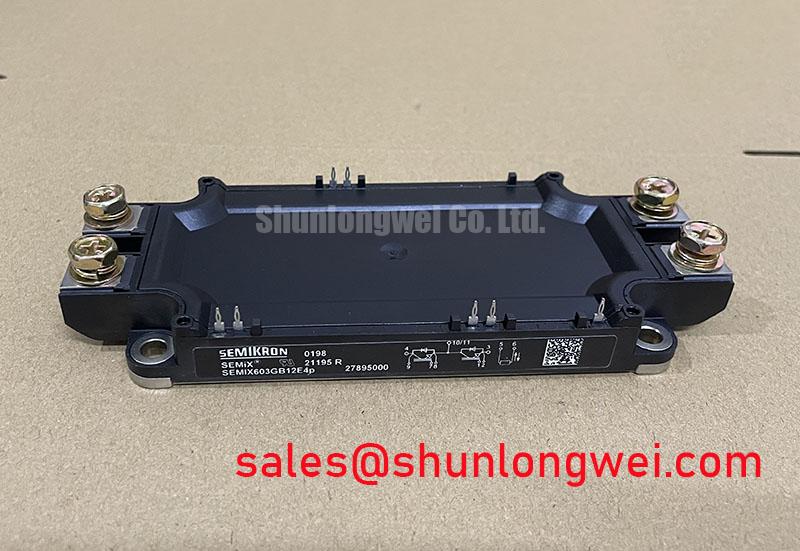

SEMIX603GB12E41P | 1200V 603A IGBT Module with Press-Fit & Shunts

An Engineering-Grade Overview of the SEMIX603GB12E41P IGBT Module

The SEMIX603GB12E41P is a 1200V, 603A IGBT module that delivers exceptional reliability and simplified system integration through solder-free press-fit technology and integrated current-sense shunts. This module leverages Trench IGBT 4 technology to achieve a low collector-emitter saturation voltage (Vce(sat)) of 1.70V at nominal current, ensuring high operational efficiency. Key benefits include superior thermal cycling endurance and a simplified current feedback design. By eliminating solder joints, a primary failure point in high-power applications, this module directly enhances system longevity. Best fit for high-reliability motor drives up to 250 kW where simplified current sensing and long-term operational stability are critical design goals.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal and Electrical Performance

The technical specifications of the SEMIX603GB12E41P are optimized for robust performance in high-power switching applications. The low VCE(sat) is a direct indicator of minimized conduction losses, which can be thought of like a water valve that offers very little resistance when fully open, allowing more current to pass through without wasting energy. This efficiency is critical for thermal management and overall system performance.

| Parameter | Value | Conditions |

|---|---|---|

| Absolute Maximum Ratings (per IGBT) | ||

| Collector-Emitter Voltage (Vces) | 1200 V | Tj = 25 °C |

| Continuous Collector Current (Ic,nom) | 603 A | Tc = 25 °C |

| Continuous Collector Current (Ic) | 442 A | Tc = 80 °C |

| Operating Junction Temperature (Tj,op) | -40 to +150 °C | |

| IGBT Characteristics (per IGBT) | ||

| Collector-Emitter Saturation Voltage (Vce(sat)) | 1.70 V (typ.) / 2.10 V (max.) | Ic = 450 A, Tj = 25 °C, Vge = 15 V |

| Turn-On Switching Energy (Eon) | 60 mJ (typ.) | Ic = 450 A, Vce = 600 V, Tj = 125 °C |

| Turn-Off Switching Energy (Eoff) | 59 mJ (typ.) | Ic = 450 A, Vce = 600 V, Tj = 125 °C |

| Thermal Resistance, Junction to Case (Rth(j-c)) | 0.075 K/W | per IGBT |

| FWD Characteristics (per Diode) | ||

| Diode Forward Voltage (Vf) | 1.75 V (typ.) / 2.15 V (max.) | If = 450 A, Tj = 25 °C |

| Reverse Recovery Charge (Qrr) | 89 µC (typ.) | If = 450 A, Tj = 125 °C |

Download the SEMIX603GB12E41P datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Industrial Drives and Power Conversion

The SEMIX603GB12E41P is engineered for applications where operational uptime and design efficiency are paramount. Its features translate directly into tangible system-level advantages.

- Industrial Motor Drives: In demanding applications such as a high-power Variable Frequency Drive (VFD), the primary engineering challenge is ensuring reliability over millions of load cycles. These cycles induce thermal stress that leads to solder fatigue, a common failure mode in conventional modules. The SEMIX603GB12E41P's press-fit pins create a gas-tight, cold-welded connection that is immune to this wear-out mechanism, significantly increasing the VFD's operational lifespan and reducing total cost of ownership.

- Uninterruptible Power Supplies (UPS): The module's high current handling and robust thermal performance ensure reliable power conversion and continuity for critical infrastructure. The integrated shunts simplify monitoring and protection circuits, leading to a more compact and cost-effective UPS design.

- Solar and Wind Inverters: The combination of low switching losses from the Trench IGBT 4 silicon and the CAL 4 freewheeling diodes maximizes energy conversion efficiency, increasing the annual energy production of renewable energy systems.

What is the primary benefit of its press-fit design? Enhanced long-term reliability by eliminating solder fatigue. This module's architecture makes it an excellent foundation for scalable inverter platforms. For systems with lower power requirements, the related SEMIX453GB12E41P offers similar technological benefits in a lower current rating.

Technical Deep Dive

A Closer Look at Press-Fit and Integrated Shunt Technology for Robust System Design

The two most impactful design choices in the SEMIX603GB12E41P are the implementation of press-fit connections and the integration of current-sense shunts. The press-fit system forms a "cold weld" between the module's pins and the PCB, ensuring an extremely low and stable contact resistance over the product's entire lifetime. This mechanical connection is far more resilient to thermal and vibrational stress than a standard solder joint. The difference is analogous to a bolted structural connection versus a glued one; the bolted joint is inherently more robust and predictable under repeated stress cycles, which is precisely what an IGBT module experiences in a drive application.

Furthermore, integrating the current-sense shunts directly into the module provides a significant advantage for the control system. It places the measurement point electrically close to the IGBT chip, minimizing parasitic inductance in the feedback loop. This results in a cleaner and more accurate current signal for the controller, which is crucial for achieving the high-dynamic performance required in precision Servo Drive systems. It also protects the vital DC link capacitor from excessive ripple currents by enabling faster protective responses. This integration simplifies the bill of materials and reduces potential EMI noise pickup points compared to using external hall-effect sensors.

Frequently Asked Questions (FAQ)

Engineering Questions on the SEMIX603GB12E41P

What is the primary engineering advantage of the press-fit technology in the SEMIX603GB12E41P?

The core advantage is a significant increase in reliability and operational lifetime. By creating a solder-free interface, it completely eliminates solder joint fatigue and cracking, which is one of the leading causes of failure in power modules subjected to frequent temperature cycling. This results in a lower total cost of ownership and higher system availability.

How do the integrated current-sense shunts simplify the design of a motor drive's control system?

Integrated shunts eliminate the need for external, bulky, and often expensive current sensors (like Hall-effect sensors). This simplifies the PCB layout, reduces the overall component count and system cost, and minimizes potential electromagnetic interference (EMI) loops. The result is a more compact, cost-effective, and reliable control system with a faster design cycle.

For inquiries regarding the SEMIX603GB12E41P and its suitability for your specific power conversion project, our technical specialists are available to provide detailed information and support your design process.