Content last revised on January 8, 2026

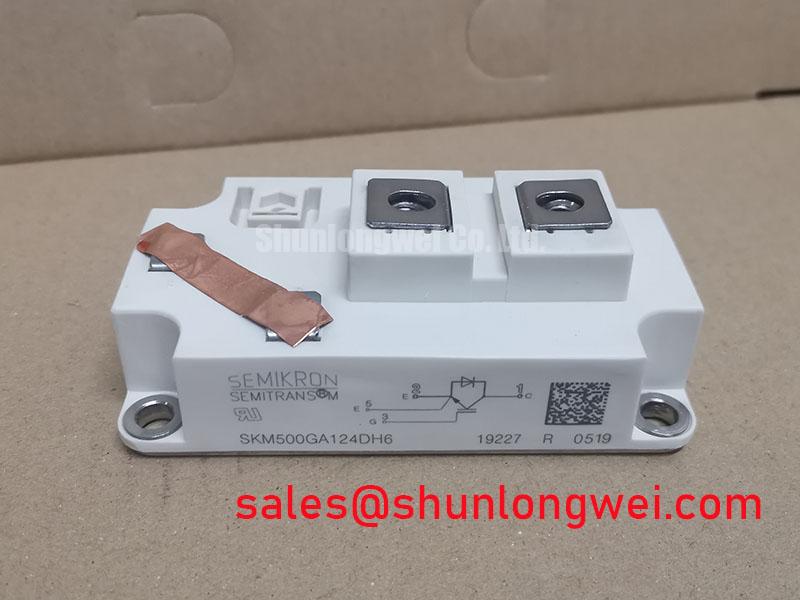

SKM400GAR12T4D: 1200V Fast IGBT Module for High-Frequency Power Conversion

Product Overview

The SKM400GAR12T4D is a high-performance IGBT module engineered for demanding, high-frequency power conversion systems. It integrates Semikron's advanced 4th generation fast trench IGBT (IGBT4) with a complementary soft-switching CAL4 freewheeling diode. This component is optimized to deliver minimal switching and conduction losses, providing a crucial advantage in applications where efficiency and power density are primary design drivers. Key specifications include: 1200V VCES | 400A ICnom | 1.7V VCE(sat) (typ). The principal engineering benefits are significantly reduced thermal load and the ability to design more compact magnetic components. What is the primary benefit of its IGBT4 technology? Drastically lower switching losses, enabling efficient operation at higher frequencies. For high-frequency industrial applications requiring robust and efficient power switching, this 1200V module provides a superior engineering foundation.

Application Scenarios & Value

System-Level Benefits in High-Frequency Welding and Power Supplies

The SKM400GAR12T4D is particularly suited for power systems operating in the upper-frequency ranges, such as advanced welding power supplies, high-frequency DC/DC converters, and uninterruptible power supplies (UPS). Consider the engineering challenge in designing a portable, high-power inverter welder: the primary goal is to minimize size and weight without compromising power output or arc stability. By enabling efficient operation at frequencies up to 20 kHz, the SKM400GAR12T4D allows designers to specify smaller, lighter, and more cost-effective transformers and inductors. The module's low total switching losses (Eon + Eoff) directly reduce the waste heat that must be managed, simplifying the thermal design and further contributing to a more compact final product. This capability makes it a cornerstone component for next-generation, high-power-density designs. For systems demanding even greater current capacity in a similar package, the SKM600GB12M7 offers a higher current rating.

- High-Frequency Welding Inverters

- Industrial Switched-Mode Power Supplies (SMPS)

- High-Power DC/DC Converters

- Dynamic Brake Choppers in Servo Drives

- Uninterruptible Power Supplies (UPS)

Key Parameter Overview

Decoding the Specs for Efficient High-Frequency Operation

The technical specifications of the SKM400GAR12T4D are tailored to minimize power loss and maximize thermal stability. The low VCE(sat) reduces heat during the on-state, while the optimized switching energies are critical for efficiency at high frequencies. The thermal resistance is a key indicator of the module's ability to transfer heat away from the semiconductor junction.

| Parameter | Symbol | Condition | Value | Unit |

|---|---|---|---|---|

| Collector-Emitter Voltage | VCES | Tj = 25 °C | 1200 | V |

| Nominal Collector Current | ICnom | Tcase = 80 °C | 400 | A |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 400 A, Tj = 125 °C | 1.7 (typ.) / 2.15 (max.) | V |

| Turn-on Switching Energy | Eon | Tj = 125 °C, IC = 400 A | 34 | mJ |

| Turn-off Switching Energy | Eoff | Tj = 125 °C, IC = 400 A | 45 | mJ |

| Thermal Resistance, Junction to Case | Rth(j-c) | per IGBT | 0.1 | K/W |

| Short Circuit Withstand Time | tpsc | Tj = 125 °C, VGE ≤ 15V | 10 | µs |

| Maximum Junction Temperature | Tjmax | - | 150 (operating) / 175 (max) | °C |

Frequently Asked Questions (FAQ)

What is the key advantage of the CAL4 diode technology in the SKM400GAR12T4D?

The 4th generation Controlled Axial Lifetime (CAL) diode is engineered for soft and fast reverse recovery. This minimizes voltage overshoot and oscillations during IGBT turn-on, which reduces electromagnetic interference (EMI) and lessens the stress on the IGBT. This "soft" behavior is critical for achieving reliable performance in high-frequency circuits.

How does the low VCE(sat) of 1.7V (typ.) directly benefit my design?

VCE(sat) is the voltage drop across the IGBT when it is fully on. A lower value signifies lower conduction power loss (P = VCE(sat) * IC). For a 400A current, this directly translates to reduced heat generation. This allows for the use of a smaller, more cost-effective heatsink, increases overall system efficiency, and improves the module's long-term reliability by operating at a lower junction temperature.

What makes this module particularly suitable for an IGBT for 20 kHz welding applications?

Three core features align it for this application: the fast IGBT4 chip minimizes switching losses, which become the dominant loss factor at high frequencies; the efficient CAL4 diode handles the freewheeling currents with low recovery losses; and the excellent thermal resistance (0.1 K/W) of the Direct Bonded Copper (DBC) baseplate efficiently extracts the generated heat, ensuring the module operates within its Safe Operating Area (SOA).

Is the SKM400GAR12T4D a complete half-bridge module?

No, the 'GAR' designation in this SEMITRANS 2 package indicates a single switch or chopper configuration. It contains one 1200V IGBT and one anti-parallel freewheeling CAL4 diode. To build a half-bridge, two of these modules would be required. For a full H-bridge, four modules are needed.

Technical Deep Dive

A Closer Look at the IGBT4 and CAL4 Technology Synergy

The performance of the SKM400GAR12T4D is fundamentally rooted in the synergy between its silicon components. The "IGBT4" designation refers to a fast trench-gate design. This structure allows for a higher density of charge carriers when the device is on, which is a primary reason for its low VCE(sat). Think of it like a water valve: a trench gate design is like a ball valve that opens a wide, unobstructed path, allowing a high flow rate (current) with very little pressure drop (voltage loss). More importantly, this structure is optimized to quickly remove charge carriers during turn-off, significantly reducing the "tail current" that is a major source of switching losses in older IGBT technologies. This rapid on-off capability is what enables efficient operation at 20 kHz. Paired with the soft-recovery CAL4 diode, which prevents abrupt current changes, the combination provides a controlled and efficient switching cycle, reducing EMI and improving the reliability of the entire power stage. Understanding these core technologies is key to effective IGBT module selection.

Strategic Design Considerations

Integrating the SKM400GAR12T4D empowers engineering teams to push the boundaries of power density and efficiency. Its technological foundation in fast-switching silicon is not just an incremental improvement; it is an enabler for system-level innovation. By facilitating operation at higher frequencies, this module supports the broader industry trend towards smaller, lighter, and more energy-efficient power conversion systems. When evaluating this component, the focus should extend beyond basic ratings to its total impact on system size, cooling requirements, and ultimately, the total cost of ownership. For design teams developing next-generation industrial power systems, the SKM400GAR12T4D offers a robust building block for achieving competitive performance targets.