Content last revised on January 15, 2026

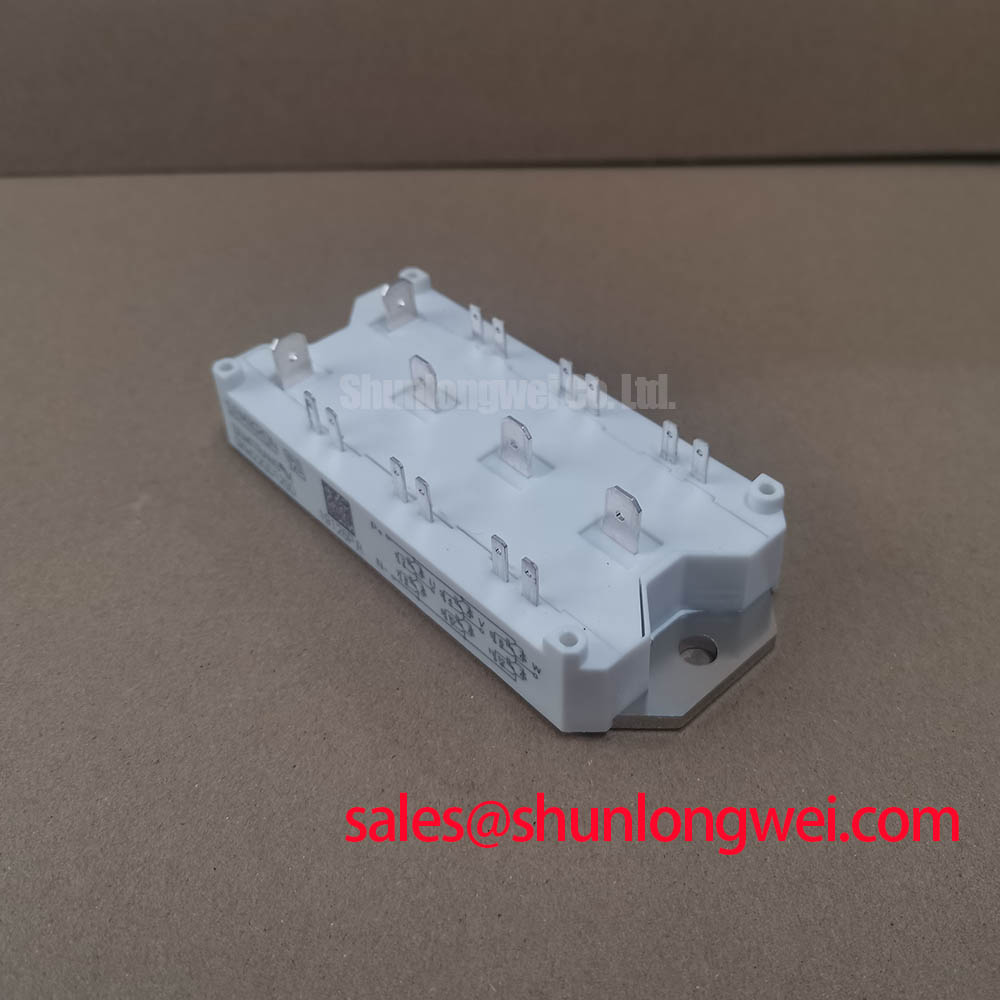

Semikron SKM22GD125D | Robust 1200V Half-Bridge IGBT for Demanding Drives

The Semikron SKM22GD125D is an engineering workhorse, designed for power conversion systems that demand a fine balance of efficiency, reliability, and thermal performance. Housed in the industry-proven SEMITRANS 2 package, this 1200V half-bridge IGBT module from Semikron provides a robust building block for designers developing high-power inverters and converters.

- Optimized for 3-Phase Systems: With a 1200V blocking voltage and a 22A nominal current rating, it's perfectly suited for applications running on 380V to 480V AC lines.

- Superior Efficiency: Integrates advanced Trench Field-Stop IGBT4 technology, delivering remarkably low conduction and switching losses, which directly translates to reduced heat generation and smaller heatsink requirements.

- Enhanced Diode Performance: Features a co-packaged CAL (Controlled Axial Lifetime) freewheeling diode known for its soft-recovery characteristics, minimizing voltage overshoots and electromagnetic interference (EMI).

- Proven Mechanical Reliability: Built on the SEMITRANS platform with a copper baseplate, ensuring excellent thermal transfer and mechanical stability for long operational life under demanding thermal cycling conditions.

Engineering Breakdown: Trench Gate and CAL Diode Synergy

The performance of the SKM22GD125D is rooted in the synergy between its core silicon components. The use of Trench Field-Stop IGBT technology creates a fundamental advantage. Unlike older planar gate designs, the trench structure allows for higher channel density, leading to a significantly lower on-state voltage drop (VCE(sat)). Simultaneously, the integrated field-stop layer drastically reduces the turn-off "tail current," minimizing switching losses (Eoff). This optimized trade-off is critical for achieving high efficiency in modern power electronics.

Complementing the IGBT is the Semikron CAL Diode. A fast but "snappy" recovery in a freewheeling diode can induce high voltage spikes and ringing, creating EMI and stressing the IGBT. The CAL diode is engineered for a "soft" recovery. This means it turns off smoothly, absorbing energy gracefully without causing disruptive oscillations. For a design engineer, this translates into a more stable system, simplified snubber circuit design, and an easier path to passing EMC compliance tests.

Critical Specifications at a Glance: SKM22GD125D

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (V_CES) | 1200 V |

| Continuous Collector Current (I_C @ T_c=80°C) | 29 A |

| Collector-Emitter Saturation Voltage (V_CE(sat), typ. @ I_C,nom, 25°C) | 1.85 V |

| Thermal Resistance, Junction-to-Case (R_th(j-c) per IGBT) | 0.6 K/W |

| Short Circuit Withstand Time (t_psc) | 10 µs |

Where the SKM22GD125D Excels: Application Deep Dive

The SKM22GD125D is not a niche component; it's a versatile power module designed for high-performance in several key industrial applications:

- Motor Drives: In Variable Frequency Drive (VFD) and servo applications, the low overall power losses enable higher power density and reduce the size and cost of the cooling system. Its robust design ensures reliability in the harsh electrical and thermal environments typical of industrial motor control. For precision applications, explore the role of IGBTs in robotic servo drives.

- UPS and Power Supplies: The high reliability and soft-switching characteristics of the CAL diode make this module an excellent choice for uninterruptible power supplies (UPS). It contributes to a clean output waveform and system stability, which are critical for protecting sensitive loads.

- Welding and Induction Heating: These applications subject components to intense power pulses and potential short-circuit conditions. The module's specified short-circuit withstand time and excellent thermal conductivity via the copper baseplate provide the necessary ruggedness to survive in these demanding environments. Discover more about IGBTs in high-frequency induction heating.

Frequently Asked Questions for Design Engineers

What are the recommended gate drive voltage levels for the SKM22GD125D?

For optimal performance, a +15V gate voltage is recommended for turn-on. While 0V can be used for turn-off, implementing a negative gate voltage (e.g., -8V to -15V) is best practice. This provides a stronger buffer against the Miller effect, preventing parasitic turn-on in noisy, high-dV/dt environments and improving overall system immunity. For more detailed guidance, review these practical tips for robust gate drive design.

How important is the mounting procedure for thermal performance?

It is absolutely critical. The module's low thermal resistance is only realized with proper mounting. This involves applying a thin, even layer of high-quality thermal interface material (TIM) and tightening the mounting screws to the torque specified in the datasheet. Uneven pressure or incorrect TIM application can create voids, drastically increasing the thermal resistance and leading to premature failure from overheating.