Content last revised on January 27, 2026

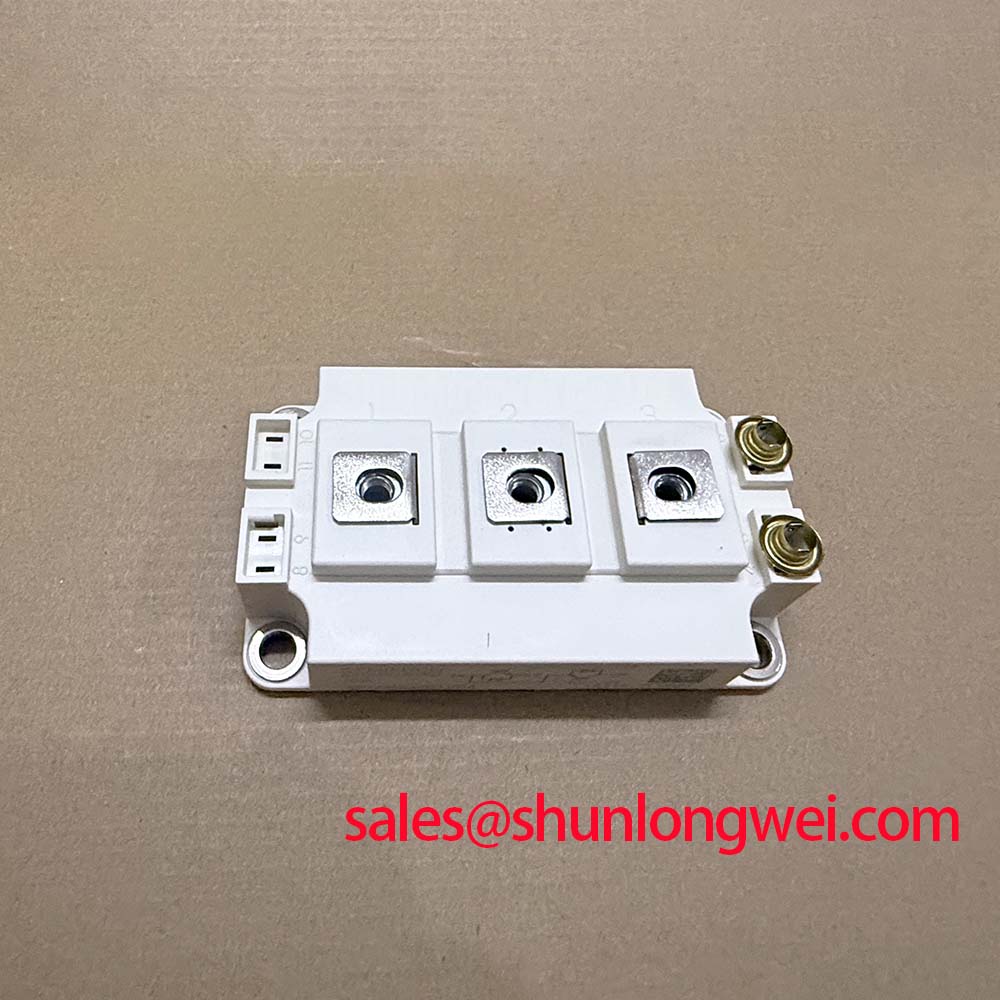

SEMIX151GB12E4V4: 1200V Press-Fit IGBT Module for High-Reliability Power Conversion

An Engineering-Focused Overview of the SEMiX 4 Half-Bridge Module

The SEMIX151GB12E4V4 is a 1200V half-bridge IGBT module engineered to provide exceptional long-term reliability and thermal efficiency in demanding industrial power conversion systems. Leveraging Semikron's Trench IGBT4 technology, it delivers a potent combination of low conduction losses and robust performance. Top Specs: 1200V | 225A (Nominal) | VCE(sat) 1.9V (typ.). Its key benefits include superior thermal cycling capability and simplified, solder-free assembly. This module directly addresses the need for dependable power stages in environments where mechanical vibration and thermal stress are significant design challenges. What is the primary benefit of its press-fit design? Enhanced long-term reliability by eliminating solder fatigue points. For medium-power industrial drives prioritizing operational lifetime and simplified manufacturing, this module's press-fit design offers a distinct advantage.

Key Parameter Overview

Decoding the Specifications for Enhanced System Reliability

The electrical and thermal characteristics of the SEMIX151GB12E4V4 are optimized for efficiency and durability in real-world operating conditions. The parameters below form the basis for robust system design, from thermal management to gate drive optimization.

| Parameter | Symbol | Condition | Value | Engineering Interpretation & Value |

|---|---|---|---|---|

| Collector-Emitter Voltage | Vces | Tj = 25 °C | 1200 V | Provides the necessary voltage margin for operation on standard 400V/480V AC lines, ensuring safety and reliability against voltage transients. |

| Continuous Collector Current | Ic,nom | Tc = 25 °C | 150 A | Defines the nominal current handling capability, suitable for a range of medium-power motor drives and inverters. |

| Max. Collector Current | Ic | Tc = 80 °C | 225 A | Specifies the practical continuous current capacity at a more typical case temperature, a critical value for thermal design. |

| Collector-Emitter Saturation Voltage | VCE(sat) | Ic = 150 A, Tj = 125 °C | 1.9 V (typ.) | Lower Conduction Losses: This low voltage drop is analogous to low friction in a mechanical system; it directly translates to less heat generated during operation, improving overall inverter efficiency. |

| Thermal Resistance, Junction to Case | Rth(j-c) | per IGBT | 0.17 K/W | Efficient Heat Transfer: This value represents the efficiency of the heat's "exit path" from the active silicon to the heatsink. A lower Rth(j-c) allows for a smaller, more cost-effective cooling solution or higher power output for a given heatsink. |

| Short Circuit Withstand Time | tsc | Vcc = 800 V, Vge ≤ 15 V | 10 µs | A critical safety parameter indicating the module's ability to survive a direct short-circuit event for a brief period, allowing protection circuits time to react. |

| Internal Gate Resistor | Rg,int | - | 2.5 Ω | Optimized for a balance between switching speed and controlling voltage overshoots (Vce,peak), contributing to improved EMI performance. |

Application Scenarios & Value

Achieving System-Level Benefits in Industrial Power Systems

The SEMIX151GB12E4V4 is engineered for applications where operational uptime and resilience to harsh conditions are paramount. Its unique construction provides tangible value beyond its electrical specifications.

High-Fidelity Engineering Scenario: Variable Frequency Drives (VFDs) for Conveyor Systems. In manufacturing and logistics, conveyor systems are subjected to constant start/stop cycles, mechanical vibrations, and fluctuating loads. A primary challenge for VFDs in this environment is the long-term degradation of solder joints within power modules due to thermal cycling and vibration, leading to premature failure. The SEMIX151GB12E4V4's solder-free press-fit pins and spring-loaded main contacts create a direct, high-pressure connection to the PCB and busbars. This design completely eliminates solder fatigue as a failure mechanism, dramatically increasing the drive's reliability and service life. The integrated NTC thermistor further supports this by enabling precise temperature monitoring for predictive maintenance, a key feature in modern industrial automation systems.

Additional core applications include:

- Solar Inverters: The module's high efficiency (low VCE(sat)) and robust thermal performance are critical for maximizing energy harvest and ensuring reliability in central or string inverters.

- Uninterruptible Power Supplies (UPS): The combination of reliability and power density makes it a strong candidate for commercial and industrial UPS systems that must guarantee power continuity.

- Welding Power Supplies: Capable of handling the high-current, pulsed loads characteristic of advanced welding applications.

For systems requiring higher current handling within a similar package, the related SEMIX303GB12E4S offers an increased current rating while maintaining the benefits of the SEMiX 4 platform.

Frequently Asked Questions (FAQ)

What are the primary advantages of the press-fit and spring contact technology used in the SEMIX151GB12E4V4?

The main advantages are enhanced reliability and simplified manufacturing. Press-fit pins create a gas-tight, solder-free connection to the control PCB, eliminating thermal fatigue failures associated with solder joints. Spring-loaded main contacts ensure a consistent, high-pressure connection to the DC link and AC output busbars, which is highly resistant to vibration and thermal expansion, making it ideal for harsh industrial environments.

How does the integrated NTC thermistor benefit the system design?

The integrated NTC thermistor provides a direct, real-time measurement of the module's baseplate temperature. This allows the system controller to implement precise over-temperature protection, preventing thermal runaway. It also enables sophisticated thermal management strategies, such as derating power under extreme conditions or providing data for predictive maintenance algorithms in a Variable Frequency Drive (VFD).

What is the function of the CAL4F (Controlled Axial Lifetime) freewheeling diode?

The CAL4F diode is an advanced freewheeling diode engineered for "soft" switching behavior. This means it has a low reverse recovery peak current (Irrm) and smooth recovery characteristics. The engineering benefit is a significant reduction in electromagnetic interference (EMI) and lower voltage stress on the IGBT during turn-on, contributing to higher system reliability and potentially reducing the need for extensive filtering components.

Is a negative gate voltage required for turning off the SEMIX151GB12E4V4?

While the datasheet specifies characteristics with a -15V gate-emitter voltage (Vge), a negative turn-off voltage is a standard best practice for IGBT modules of this power class. It provides a higher noise margin, ensuring the device remains securely off and preventing parasitic turn-on, especially in noisy, high dV/dt environments typical of high-power inverters.

What is the significance of the 0.17 K/W thermal resistance (Rth(j-c))?

This value quantifies how effectively heat can be transferred from the IGBT silicon chip to the module's case. A lower value is better. A Rth(j-c) of 0.17 K/W indicates a highly efficient thermal path, meaning for every watt of power dissipated as heat, the junction temperature will only rise 0.17°C above the case temperature. This allows engineers to either push more power through the module or use a more compact and cost-effective heatsink to maintain a safe operating temperature.

Industry Insights & Strategic Advantage

Meeting the Demands of Industry 4.0 with Robust Power Electronics

The transition towards smarter, more automated industrial environments places new demands on the reliability of core components like power modules. The SEMIX151GB12E4V4's design directly supports key industry trends. Its solder-free construction aligns with the need for higher Mean Time Between Failures (MTBF) in systems that operate 24/7. Furthermore, the inclusion of an integrated NTC sensor is not just a protection feature; it is an enabler for the data-driven maintenance strategies central to Industry 4.0, allowing for condition monitoring that can prevent costly unplanned downtime.

Application Vignette

Maximizing Uptime in Commercial Solar Inverter Systems

Consider a 50kW string solar inverter deployed in a desert environment, where ambient temperatures fluctuate dramatically and long-term reliability is essential for financial return. The core challenge is managing thermal stress. During peak sun, the inverter operates at maximum power, generating significant heat. As clouds pass, power drops, and the system cools, creating a thermal cycle. Over years, these cycles can fatigue traditional solder-based power modules. The SEMIX151GB12E4V4 provides a robust solution. Its spring-based power and signal contacts are immune to the solder fatigue that plagues conventional modules, ensuring a reliable connection for the 20+ year expected lifespan of the installation. The low VCE(sat) of its Trench IGBT4 chips minimizes heat generation, reducing the burden on the cooling system and improving the inverter's overall energy conversion efficiency, ultimately delivering more power to the grid.

A Strategic Component for Future-Proof Designs

The SEMIX151GB12E4V4 represents a strategic choice for engineers developing next-generation power conversion platforms. By prioritizing a mechanical design that mitigates common failure modes, it offers a pathway to creating systems with lower total cost of ownership, enhanced field reliability, and alignment with the increasing need for intelligent, self-monitoring components in the industrial and renewable energy sectors. Its performance characteristics provide a solid foundation for designs that are not only efficient today but are built to last.