Content last revised on January 21, 2026

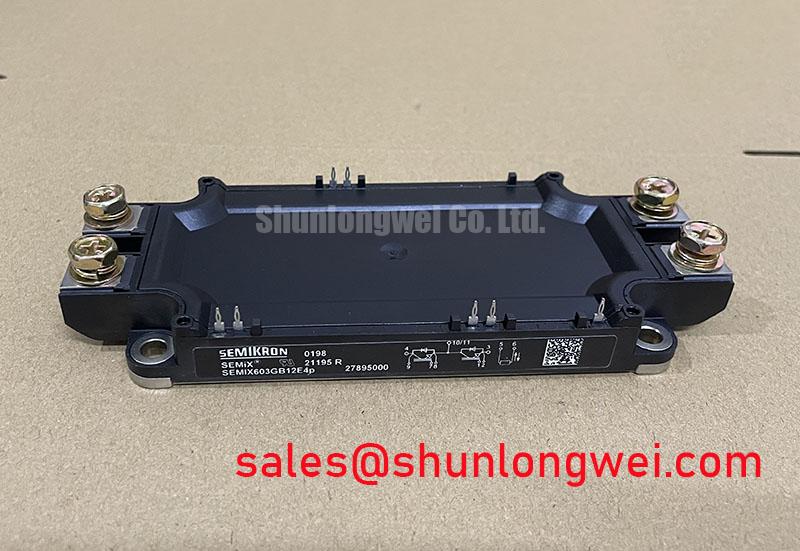

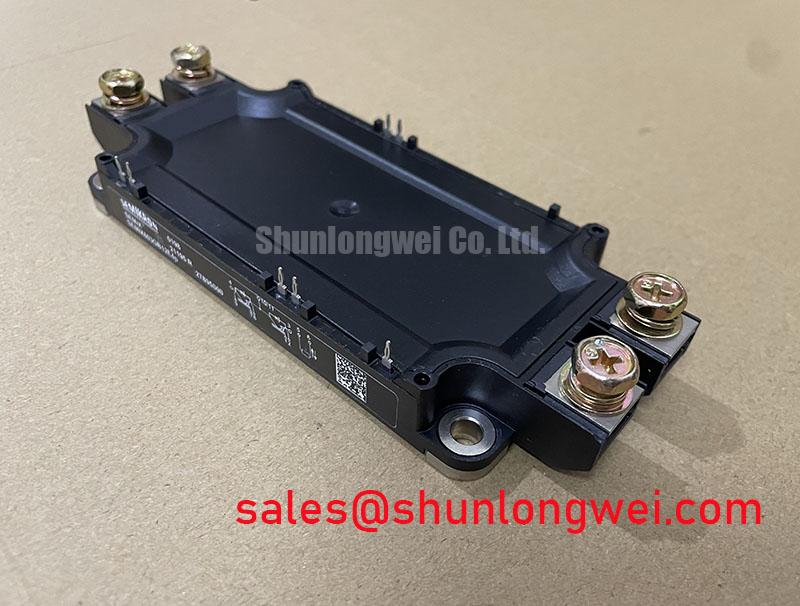

SEMIX603GB12E4P: IGBT Module for High-Power Inverters

Engineered for robust thermal performance and high power density, the SEMIX603GB12E4P IGBT half-bridge module provides a dependable foundation for demanding power conversion systems. Key Specifications: 1200V | 600A | VCE(sat) 1.9V. Its core advantages include optimized switching behavior and superior heat dissipation. This module directly addresses how to achieve reliable power cycling in high-stress applications by leveraging a construction designed for enhanced thermal transfer, ensuring consistent performance under continuous load conditions.

Application Arenas Forged for High-Power Conversion

The SEMIX603GB12E4P is tailored for high-power applications where efficient and reliable energy conversion is paramount. Its robust electrical and thermal characteristics make it a strong candidate for the core of power conversion systems across several industrial sectors. The module's architecture is particularly effective in managing the demanding cycles of modern power electronics.

- Motor Drives: In high-power industrial motor controls and Servo Drives, the module's ability to handle significant current and its optimized switching characteristics contribute to precise control and system efficiency.

- Renewable Energy Inverters: For large-scale wind turbine and solar power inverters, the module's 1200V rating and thermal stability ensure dependable grid integration and long operational life, even under fluctuating load conditions.

- Uninterruptible Power Supplies (UPS): Its high current rating and robust build are ideal for centralized UPS systems, providing stable and reliable backup power for critical infrastructure.

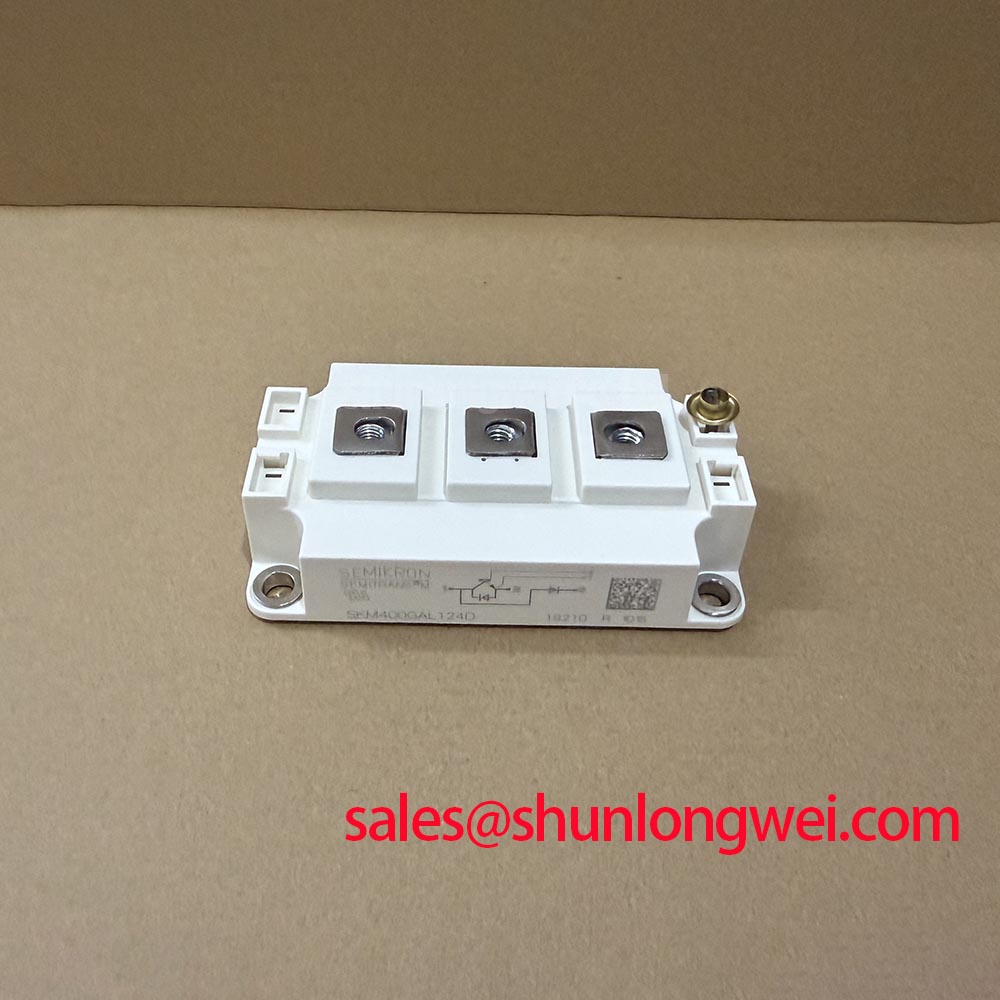

For systems where streamlined integration and higher current density are primary drivers, the SEMIX604GB12VS offers a similar voltage class with a design focused on compact power stages.

Best Fit: For systems operating up to 1200V requiring robust power cycling capability, the SEMIX603GB12E4P's low thermal resistance makes it the superior choice for maximizing long-term reliability.

Deep Dive into Component Technology

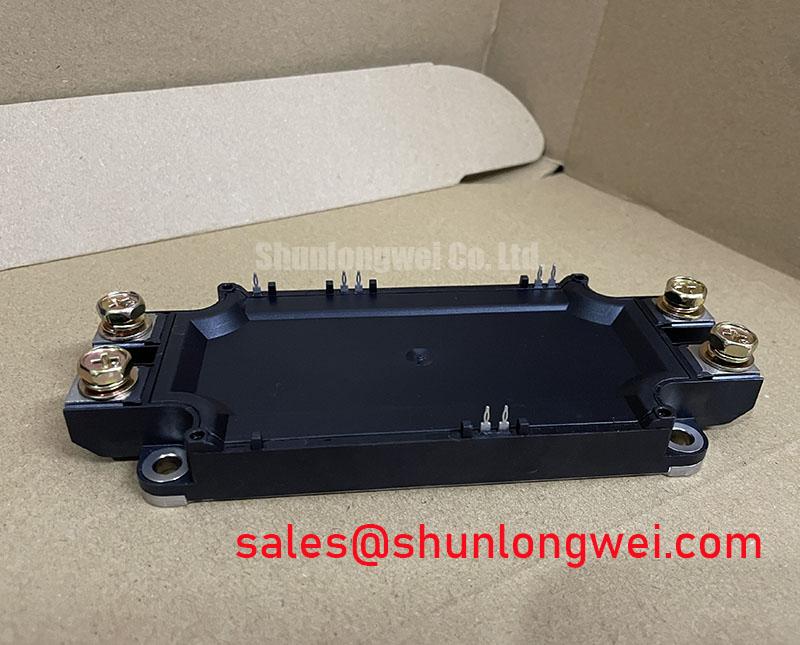

The performance of the SEMiX 3p press-fit package is fundamentally tied to its internal construction and the technologies employed. This module integrates Trench Gate IGBTs and CAL (Controlled Axial Lifetime) freewheeling diodes. The Trench Gate structure provides a lower on-state voltage drop (VCE(sat)) compared to older planar designs, which directly translates to reduced conduction losses. This is critical in applications with high duty cycles where the IGBTs spend a significant amount of time in the 'on' state. What is the benefit of a low VCE(sat)? It directly reduces the heat generated, simplifying thermal management. The co-packed CAL diodes are optimized for soft switching behavior, minimizing voltage overshoots and electromagnetic interference (EMI) during the turn-off phase of the IGBT. The press-fit pins offer a solder-free assembly process, enhancing reliability by removing the potential for solder joint fatigue failures, a common issue in applications with frequent thermal cycling.

Deployment Snapshot: Enhancing Wind Turbine Converter Uptime

A renewable energy systems integrator was tasked with improving the mean time between failures (MTBF) for a 1.5 MW wind turbine's grid-side converter. The existing solution experienced premature failures linked to thermal stress on the power modules during gusting wind conditions, which caused rapid load fluctuations. By retrofitting the converter with the SEMIX603GB12E4P, the engineering team leveraged its low thermal resistance from junction to case (Rth(j-c)). This superior thermal pathway allowed for more efficient heat extraction to the heatsink, keeping the IGBT junction temperature well within its safe operating area even during peak power generation. The result was a measurable increase in converter uptime and a reduction in unscheduled maintenance, contributing directly to a lower levelized cost of energy (LCOE) for the wind farm operator.

Core Performance Parameters at a Glance

The following parameters are critical for evaluating the SEMIX603GB12E4P in a specific system design. These metrics provide a snapshot of its electrical and thermal capabilities under defined test conditions. For a complete dataset, please refer to the official datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 1200 V |

| Continuous Collector Current (Ic) @ 25°C | 600 A |

| Collector-Emitter Saturation Voltage (VCE(sat)) | 1.9 V (Typ) @ 450A, 25°C |

| Total Power Dissipation (Ptot) | 2800 W |

| Thermal Resistance, Junction to Case (Rth(j-c)) | 0.045 K/W per IGBT |

| Short Circuit Withstand Time (tsc) | 10 µs |

Interpreting Key Specs:

The Collector-Emitter Saturation Voltage (VCE(sat)) is a direct indicator of conduction efficiency. A lower VCE(sat) means less power is converted into heat while the switch is on, improving overall system efficiency. The module's typical 1.9V is competitive for its power class.

Thermal Resistance (Rth(j-c)) acts like a bottleneck for heat flow. The lower this value, the more effectively heat generated at the semiconductor junction can be transferred to the heatsink. A low Rth(j-c) is crucial for reliability and achieving high power density.

Comparative Data for Informed Decision-Making

To assist in the evaluation process, this section provides a factual comparison of key parameters between the SEMIX603GB12E4P and another component in a similar application space. This data is intended to empower engineering decisions based on specific design priorities.

Data presented below is for informational purposes and is derived from publicly available datasheets. Final selection should be based on comprehensive testing in the target application.

| Parameter | SEMIX603GB12E4P | Generic Competing Module (1200V, ~600A) |

|---|---|---|

| Vces (Collector-Emitter Voltage) | 1200 V | 1200 V |

| Ic nom (Nominal Current) | 450 A | 450 A |

| VCE(sat) (Typical @ Ic nom) | 1.9 V | 2.1 V |

| Rth(j-c) (per IGBT) | 0.045 K/W | 0.055 K/W |

| Mounting Technology | Press-Fit | Solder Pins |

This comparison highlights how the SEMIX603GB12E4P's lower VCE(sat) and thermal resistance can translate to lower operating temperatures and higher efficiency, while its press-fit design offers a different assembly and reliability profile compared to traditional soldered modules.

Strategic Advantage in Industrial Electrification

The ongoing trend of industrial electrification and the push for higher energy efficiency place significant demands on power semiconductor modules. The SEMIX603GB12E4P is well-positioned to meet these challenges. Its design, which emphasizes low conduction losses and effective thermal management, directly supports the development of more compact and efficient high-power inverters. As regulations like the EU's Ecodesign Directive become more stringent, specifying modules that minimize energy loss is not just a performance goal but a strategic necessity. Furthermore, the reliability enhancements offered by features like press-fit pins align with the Industry 4.0 demand for systems with maximum availability and reduced lifetime maintenance costs.

Frequently Asked Questions

1. What is the primary advantage of the press-fit pin design in the SEMIX603GB12E4P?

The main benefit is enhanced long-term reliability. Press-fit connections create a high-pressure, gas-tight electrical bond without solder. This eliminates the risk of solder joint cracking and fatigue, a common failure mode in applications with significant thermal cycling, such as renewable energy inverters or heavy-duty motor drives.

2. How does the Rth(j-c) of 0.045 K/W impact my thermal design?

A lower thermal resistance from junction to case allows for more efficient heat transfer from the IGBT and diode chips to the module's baseplate and, ultimately, to your heatsink. This means for a given power loss, the chip will operate at a lower temperature, increasing reliability and lifetime. Alternatively, it allows you to push more power through the module while staying within the same temperature limits, potentially enabling a more power-dense system design.

3. Is this module suitable for paralleling to achieve higher current output?

Yes, IGBT modules like the SEMIX603GB12E4P can be paralleled. However, successful paralleling requires careful design considerations. The positive temperature coefficient of the VCE(sat) provides a degree of self-balancing for static current sharing. For dynamic (switching) performance, it is critical to ensure symmetrical gate drive layout and matched gate resistors to prevent current imbalances during turn-on and turn-off events. For a deeper understanding, consult resources on IGBT paralleling.

4. What kind of gate driver is recommended for this 1200V IGBT module?

A gate driver capable of providing a gate-emitter voltage (Vge) swing of +15V for turn-on and -8V to -15V for turn-off is typically recommended. The negative turn-off voltage is crucial to provide a strong buffer against parasitic turn-on induced by high dV/dt. The driver must also be able to supply the peak gate current required to charge and discharge the module's input capacitance quickly for efficient switching.

Future-Proofing High-Power Systems

Selecting a power module extends beyond meeting immediate electrical specifications; it's a strategic decision that impacts long-term system reliability, energy efficiency, and total cost of ownership. The SEMIX603GB12E4P, with its foundation in advanced Trench Gate IGBT technology and a package optimized for thermal resilience, provides engineers with a forward-looking component. It enables the design of power conversion platforms that are not only powerful and efficient today but are also built to withstand the operational rigors of tomorrow's industrial and renewable energy landscapes, ensuring a durable return on investment.