Content last revised on November 13, 2025

SKD 25/02: Robust 200V Three-Phase Rectifier for High-Reliability Industrial Power Systems

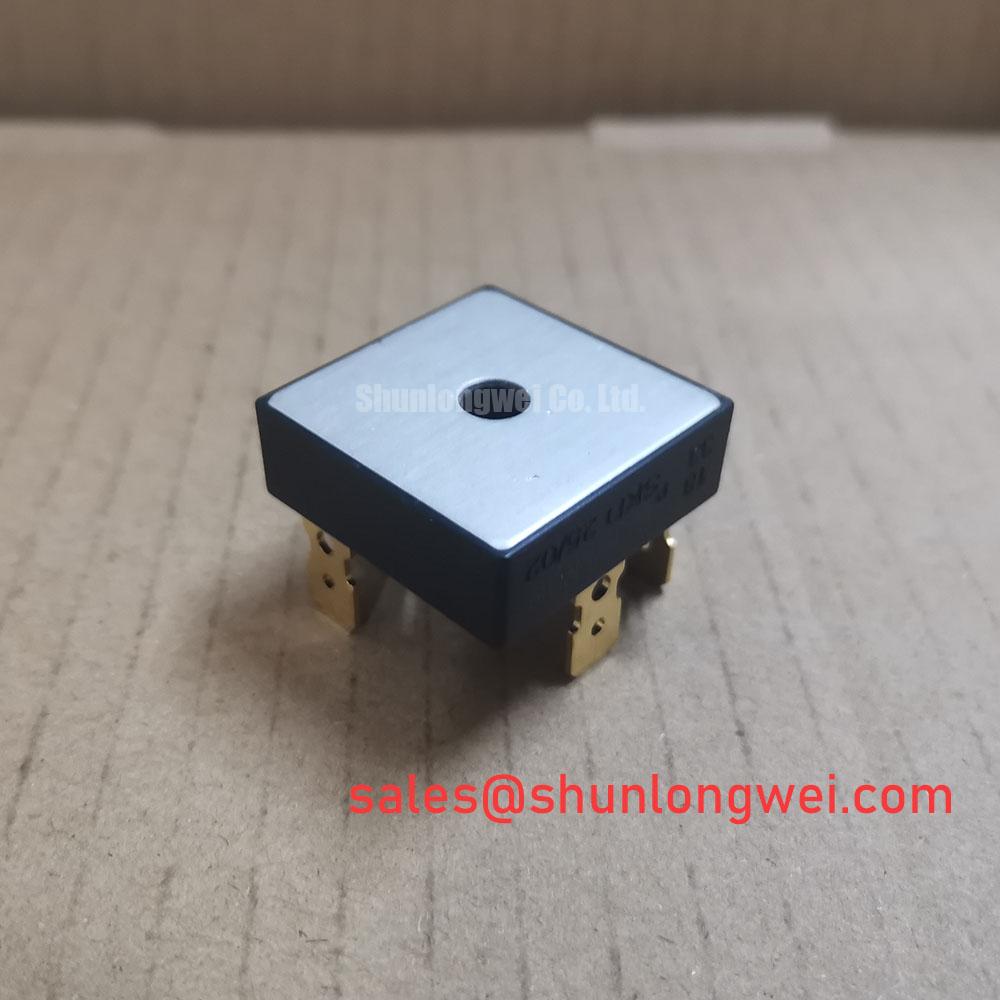

Engineered for enduring performance in demanding industrial environments, the SKD 25/02 by Semikron is a three-phase uncontrolled bridge rectifier module designed for high-reliability power conversion. Its core value lies in a construction that prioritizes mechanical stability and thermal efficiency. With key specifications of 200V | 20A | I²t = 680 A²s, this module offers significant advantages, including exceptional resilience to surge currents and simplified, cost-effective assembly. It directly addresses the need for a robust input rectification stage that can withstand the electrical stresses typical in industrial machinery. For low-voltage motor drives and power supplies where long-term operational integrity is critical, the SKD 25/02's isolated baseplate design presents a distinct engineering advantage.

Key Parameter Overview

Decoding the Electrical and Thermal Specifications for System Design

The SKD 25/02 is defined by a set of electrical and thermal characteristics that are critical for system integration, reliability, and performance. The parameters below, sourced from the official datasheet, provide the necessary data for thermal modeling, surge protection design, and overall system dimensioning.

| Electrical Characteristics (at Tvj = 25°C unless otherwise specified) | ||

|---|---|---|

| Parameter | Value | Notes |

| Repetitive Peak Reverse Voltage (VRRM) | 200 V | Defines the maximum allowable reverse voltage, suitable for low-voltage AC lines. |

| DC Output Current (ID) | 20 A | Rated at a case temperature (Tc) of 73°C. |

| Surge Forward Current (IFSM) | 370 A | Maximum non-repetitive surge current handling (10 ms), crucial for surviving inrush events. |

| I²t Value | 680 A²s | Indicates the module's thermal capacity to withstand surge energy without failure, a key metric for fuse coordination. |

| Forward Voltage (VF) | max. 2.2 V | Measured at a high forward current (IF = 150 A), impacting conduction losses. |

| Threshold Voltage (V(TO)) | 0.85 V | Essential for calculating conduction losses under operational conditions (Tvj = 150°C). |

| Thermal and Mechanical Characteristics | ||

| Parameter | Value | Notes |

| Operating Junction Temperature (Tvj) | -40 to +150 °C | Wide operating range suitable for harsh industrial settings. |

| Thermal Resistance, Junction to Case (Rth(j-c)) | 1.75 K/W | A lower value indicates more efficient heat transfer from the silicon to the heatsink. |

| Isolation Voltage (Visol) | 3000 V~ | High isolation capability (1 sec, r.m.s.) simplifies mounting and enhances safety. |

| Case Type | G 11b (SEMIPONT® 1) | Industry-standard housing with an electrically isolated metal baseplate. |

Download the SKD 25/02 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Industrial Rectification Stages

Best Fit: For industrial power supplies and small motor drives up to 5 kW requiring a dependable, easy-to-mount front-end rectifier, the SKD 25/02 provides an optimal balance of performance and long-term reliability. The module's primary application is as an input rectifier for three-phase power supplies, battery chargers, and the input rectification stage of low-power Variable Frequency Drives (VFDs).

In a typical VFD application, the rectifier's ability to handle transient events is paramount. The SKD 25/02's robust I²t rating of 680 A²s provides a crucial safety margin against the inrush current experienced when charging the DC bus capacitors. This resilience prevents premature failure and enhances the overall drive reliability. Furthermore, its electrically isolated baseplate is a significant value-add. It allows direct mounting to a common chassis or heatsink without the need for additional, thermally inefficient insulating pads. This simplifies the mechanical design, reduces assembly time and cost, and improves the thermal pathway, contributing to a more compact and reliable system. For systems requiring rectification from higher voltage lines, the related SKD100/16 offers a blocking voltage of 1600V.

Technical Deep Dive

A Closer Look at the Construction for Enhanced Durability

The SKD 25/02's reliability is not just a function of its electrical ratings but is deeply rooted in its physical construction. The module utilizes a square plastic case with an isolated metal baseplate, a design that serves two critical engineering functions. The baseplate, made of Aluminium Oxide (Al2O3) ceramic, provides excellent thermal conductivity while ensuring high electrical isolation (3000V). Think of this ceramic layer as a superhighway for heat, allowing it to escape efficiently from the diode junctions to the heatsink, while simultaneously acting as an impenetrable barrier for electricity. This direct-bonded copper (DBC) technology is superior to traditional methods that require separate insulating layers, which can degrade over time and impede heat flow. This robust thermal management is key to the module's stable performance and long operational life, especially in applications with continuous, heavy loads.

Frequently Asked Questions (FAQ)

What is the primary advantage of the SKD 25/02's Aluminium Oxide ceramic baseplate?

The primary advantage is the combination of high dielectric strength and good thermal conductivity. This allows the module to be mounted directly onto a grounded heatsink without external insulation, simplifying assembly, improving heat transfer, and enhancing overall system safety and reliability.

How does the I²t rating of 680 A²s impact protective device selection?

This rating represents the thermal energy the diodes can absorb during a short-term fault before failing. It is a critical parameter for proper fuse or circuit breaker coordination. Engineers must select a protective device with an I²t let-through value lower than 680 A²s to ensure the rectifier is protected during an overcurrent event.

To evaluate the SKD 25/02 for your next industrial power design or to explore its integration capabilities, review the datasheet and application notes for comprehensive performance data.