Content last revised on October 23, 2025.

SKKT 40/18E: Technical Analysis & Datasheet for Industrial Power Control

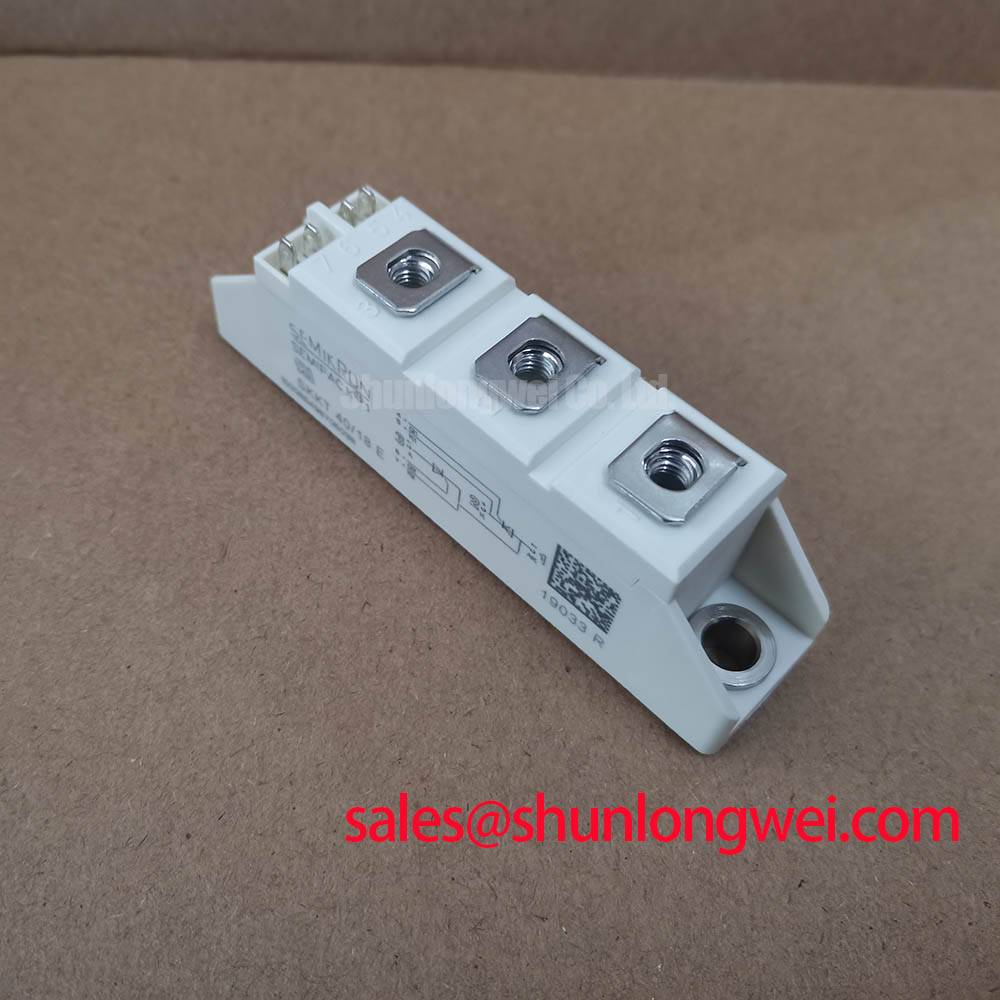

SKKT 40/18E Thyristor Module: Engineered for Durability in AC Control Applications

The SKKT 40/18E is a robust thyristor module engineered for high-reliability power control in demanding industrial environments. It delivers exceptional operational longevity through a design focused on thermal stability and robust construction. Key specifications include: 1800V | 40A | Hard Solder Technology. This module offers the primary engineering benefits of enhanced thermal cycling capability and simplified system assembly. Its hard-soldered internal joints directly address the common failure mode of solder fatigue in applications with frequent power cycles. For systems requiring robust AC phase control, such as industrial soft starters or heating systems, the SKKT 40/18E provides a durable and reliable control element.

Key Parameter Overview

A Highlight of Critical Specifications for System Design

The parameters for the SKKT 40/18E are optimized for performance and reliability in AC power control circuits. The following table highlights the specifications most critical for design engineers evaluating this module for their application. The 1800V rating provides a significant safety margin for systems operating on 400V and 690V lines.

| Parameter | Symbol | Value | Conditions |

|---|---|---|---|

| Repetitive Peak Off-State Voltage | VDRM, VRRM | 1800 V | Tj = 125 °C |

| Average On-State Current | ITAV | 40 A | Tcase = 85 °C |

| RMS On-State Current | ITRMS | 100 A | Tcase = 70 °C |

| Surge non-repetitive On-State Current | ITSM | 950 A | 10 ms, Tj = 125 °C |

| Critical rate of rise of on-state current | (di/dt)cr | 150 A/µs | Tj = 125 °C |

| Thermal Resistance, Junction to Case | Rth(j-c) | 0.33 °C/W | Per Thyristor |

| Isolation Test Voltage | Visol | 3000 V | 1 minute |

Download the SKKT 40/18E datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Delivering System-Level Reliability in Cyclical Load Environments

The SKKT 40/18E is best suited for industrial applications where controlled power delivery and long-term reliability are paramount. Its inherent robustness makes it an ideal component for AC motor soft starters, industrial temperature controllers, and AC-DC rectifiers.

Consider the engineering challenge of a conveyor system motor that starts and stops hundreds of times per day. Each cycle induces thermal stress on the power electronics. The SKKT 40/18E's use of hard solder technology directly counters this challenge by creating a more durable bond between the silicon chip and the substrate, significantly enhancing its resistance to thermal fatigue. This construction is crucial for preventing premature failure in such high-cycle applications, extending the operational life of the entire soft starter unit. What is the benefit of hard solder technology? It directly improves reliability in applications with frequent temperature changes by preventing solder fatigue failures. For applications requiring control of larger motors, the related SKKH106/16E offers a higher current handling capability within a similar package concept.

Frequently Asked Questions (FAQ)

How do the hard-soldered joints in the SKKT 40/18E improve system reliability?

Hard-soldered joints use a higher melting point solder alloy, creating a much stronger and more durable bond compared to conventional soft solder. This significantly reduces the likelihood of cracks and failures caused by the mechanical stress of repeated thermal expansion and contraction (thermal cycling), a common issue in applications like motor starters or process heaters. This leads to a longer operational lifetime and lower maintenance costs.

What is the significance of the 1800V V_RRM rating for industrial applications?

The 1800V repetitive peak reverse voltage rating provides a substantial safety margin for equipment operating on 400V, 480V, or even 690V three-phase AC lines. Industrial power grids are prone to transient voltage spikes caused by switching large loads. This high voltage rating ensures the module can withstand these common events without damage, contributing to the overall robustness of the end equipment.

Does the insulated baseplate simplify the thermal design process?

Yes. The SKKT 40/18E features an Aluminium Oxide (Al2O3) ceramic baseplate that electrically isolates the internal components from the heatsink. This eliminates the need for external insulating pads (like mica or silicone) and the associated thermal grease. This simplifies assembly, reduces component count, and ensures a consistent, reliable thermal path to the heatsink, which is a key part of effective thermal management.

What is the primary function of the two thyristors in this module?

The module contains two thyristors (also known as SCRs) connected in series with a common cathode configuration. This arrangement is typically used to control one phase of an AC load. By precisely timing the firing of the thyristors—a technique known as Phase Angle Control—engineers can regulate the amount of power delivered to the load, enabling functions like dimming lights, controlling motor speed, or regulating the output of a heating element.

Technical Deep Dive

A Closer Look at Hard Solder Technology for Enhanced Operational Longevity

The distinction between standard and high-reliability power modules often lies in the manufacturing processes that are not immediately obvious from headline specifications. The SKKT 40/18E employs hard solder technology, a critical feature for ensuring long-term performance. In a standard module, repeated heating and cooling cause the silicon die and its copper substrate to expand and contract at different rates. Over thousands of cycles, this puts immense strain on the soft solder joint, leading to micro-cracks and eventual failure.

What is the module's key construction advantage? Its hard-soldered joints provide superior resistance to thermal fatigue. Hard soldering utilizes alloys that are mechanically stronger and have a higher melting point. This creates a joint that is far more resilient to the stresses of thermal cycling. Thinking of it in mechanical terms, it's like the difference between gluing two metal plates together versus welding them. While glue might hold for a while, a proper weld is integral to the structure and can withstand constant vibration and stress far more effectively. This manufacturing choice positions the SKKT 40/18E as a component built for endurance in cyclical industrial machinery.

Strategic Component Selection for Reduced Ownership Cost

Specifying components like the SKKT 40/18E is a strategic decision that extends beyond initial procurement cost. By prioritizing construction technologies that enhance reliability, such as hard soldering and insulated substrates, engineers can significantly reduce the total cost of ownership. The value is realized through extended equipment uptime, fewer field service calls, and greater system resilience in the face of harsh operational conditions. This focus on durability is a cornerstone of designing robust and commercially successful industrial power systems. For a deeper understanding of power module technologies, resources from manufacturers like Semikron provide valuable context.