SKM200GAL1200KL IGBT Module: Thermal Performance Specs

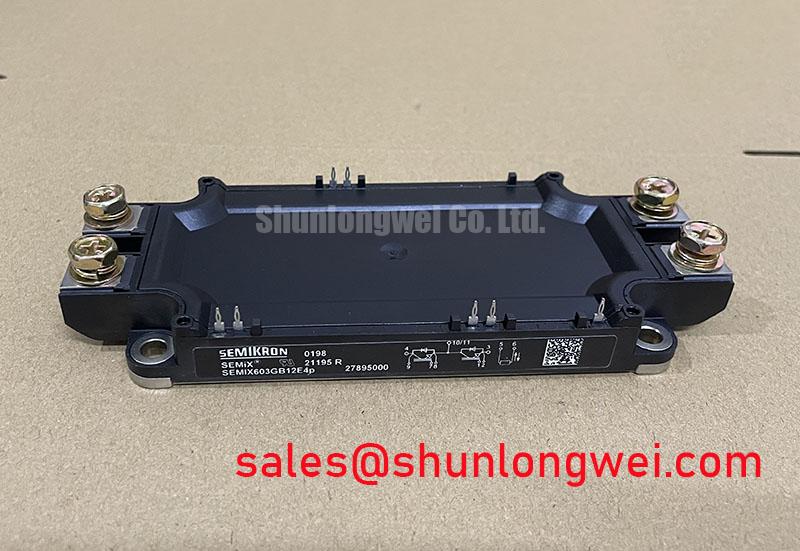

Technical Overview of the SEMITRANS 2 IGBT Module

The SKM200GAL1200KL delivers superior thermal management and operational longevity for high-power systems through its advanced construction. This SEMITRANS 2 half-bridge module is built on a foundation of reliability, integrating Trench Gate IGBT technology with a CAL (Controlled Axial Lifetime) freewheeling diode. Its core specifications are: 1200V VCES | 200A IC | 0.1 K/W Rth(j-c) per IGBT. Key engineering benefits include exceptional heat dissipation and enhanced power cycling durability. The module's design, featuring an isolated copper baseplate, directly addresses the engineering challenge of simplifying thermal assembly by providing excellent heat transfer while ensuring high electrical isolation, thus reducing the need for complex insulating materials between the module and the heatsink.

Engineering for Thermal Stability: A Closer Look

The operational reliability of a power module is intrinsically linked to its ability to manage heat. The SKM200GAL1200KL is architected around this principle. At its core is an Aluminium Oxide (Al2O3) ceramic substrate bonded to an isolated copper baseplate. This construction creates a highly efficient pathway for thermal energy to move from the semiconductor junctions to the heatsink. What is the primary benefit of its construction? It ensures consistent electrical isolation while maximizing thermal conductivity, a critical factor for system safety and performance.

This design minimizes the junction-to-case thermal resistance (Rth(j-c)), a parameter that functions much like the width of a pipe determines water flow. A lower thermal resistance value indicates a wider 'pipe' for heat, allowing it to be evacuated more effectively. This efficiency enables the module to operate at higher power levels or within more constrained thermal budgets, contributing directly to increased power density and extended component life. For more on the importance of thermal performance, see our guide on unlocking IGBT thermal performance.

Data for Your Design Matrix

In power electronics design, component selection is a process of data-driven trade-offs. To facilitate this, the table below provides a factual comparison based on key thermal and electrical parameters. The SKM200GAL1200KL is presented alongside typical values for a generic module in a similar class to highlight the specific data points relevant for thermal performance analysis. This information is intended to support your engineering evaluation and system modeling. For applications demanding different current ratings or configurations, the SKM300GB128D presents an alternative with a higher current capacity within the same voltage class.

| Parameter | SEMIKRON SKM200GAL1200KL | Typical Competing Module | Implication for Design |

|---|---|---|---|

| Thermal Resistance, Junction-to-Case (Rth(j-c) per IGBT) | 0.10 K/W | ~0.12 - 0.15 K/W | Facilitates superior heat extraction, potentially allowing for smaller heatsinks or higher operational margins. |

| Collector-Emitter Saturation Voltage (VCE(sat)) @ ICnom, Tj=125°C | 2.0 V (Typ.) | ~2.2 - 2.4 V | Lower typical saturation voltage translates directly to reduced conduction losses and less waste heat generation. |

| Module Package | SEMITRANS 2 | Various | Industry-standard housing ensures mechanical predictability and compatibility with existing assembly processes. |

Core Specifications for Thermal and Electrical Performance

The following parameters are critical for system design, thermal simulation, and performance validation. The values presented are extracted from the official manufacturer's datasheet to ensure accuracy for your engineering calculations.

| Key Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 1200 V |

| Continuous Collector Current (IC) @ Tc=80°C | 200 A |

| Collector-Emitter Saturation Voltage (VCE(sat), typ. @ 200A, 125°C) | 2.0 V |

| Thermal Resistance, Junction-to-Case (Rth(j-c) per Diode) | 0.17 K/W |

| Isolation Voltage (Visol) | 4000 V |

| Max. Junction Temperature (Tjmax) | 175 °C |

Interpreting the Data

- VCE(sat) (Collector-Emitter Saturation Voltage): This value is a primary indicator of conduction losses. The low typical VCE(sat) of 2.0V means that when the IGBT is fully on, it dissipates less power as heat, which is fundamental to achieving higher overall system efficiency. How does VCE(sat) impact performance? Lower VCE(sat) directly reduces the heat that must be managed by the cooling system.

- Rth(j-c) (Thermal Resistance, Junction-to-Case): This parameter quantifies the module's ability to transfer heat from the silicon die to the module case. The specified low values for both the IGBT (0.10 K/W) and the diode (0.17 K/W) confirm the design's focus on thermal efficiency, a key factor for reliability in demanding applications.

Powering High-Demand Industrial Systems

The robust thermal design of the SKM200GAL1200KL makes it a suitable component for a range of power conversion systems where reliability and performance under load are paramount. Its characteristics are well-aligned with the demands of modern industrial automation and energy infrastructure.

Primary Application Arenas

- Variable Frequency Drives (VFDs): In motor control applications, the module's ability to handle high currents and effectively dissipate heat is crucial for precise and reliable operation, from heavy-duty conveyors to industrial pumps.

- Solar Inverters and Wind Converters: The power cycling inherent in renewable energy generation creates thermal stress. The SKM200GAL1200KL's durable construction is designed to withstand these cycles, supporting the long-term viability of green energy systems. Explore the role of IGBTs in wind-to-grid conversion.

- Uninterruptible Power Supplies (UPS): For critical infrastructure, the reliability provided by superior thermal management ensures that backup power systems perform as expected when they are needed most.

For high-frequency industrial drives where minimizing conduction losses is the primary design driver, the SKM200GAL1200KL's low VCE(sat) establishes it as a strong candidate.

The Reliability Advantage in Modern Power Electronics

In an industrial landscape where uptime is directly tied to profitability, the long-term reliability of power components is not just a feature but a strategic asset. The design philosophy of the SKM200GAL1200KL, with its focus on thermal integrity, aligns with the industry's shift towards minimizing total cost of ownership (TCO). By engineering a module that withstands thermal stress more effectively, the service life of the end equipment—be it a Servo Drive or a large-scale UPS—is extended, and maintenance intervals are potentially increased. This focus on durability is a key enabler for building next-generation power systems that are not only powerful and efficient but also fundamentally more dependable.

Future-Proofing Your Power Stage Design

As power conversion systems continue to push the boundaries of density and performance, the foundational components must evolve accordingly. The SEMIKRON SKM200GAL1200KL represents a deliberate engineering choice for systems where thermal robustness is the cornerstone of long-term value. Integrating this module into your design provides a solid thermal foundation, enabling you to focus on system-level innovation with confidence in the power stage's ability to perform consistently over its intended operational life.