Content last revised on November 21, 2025

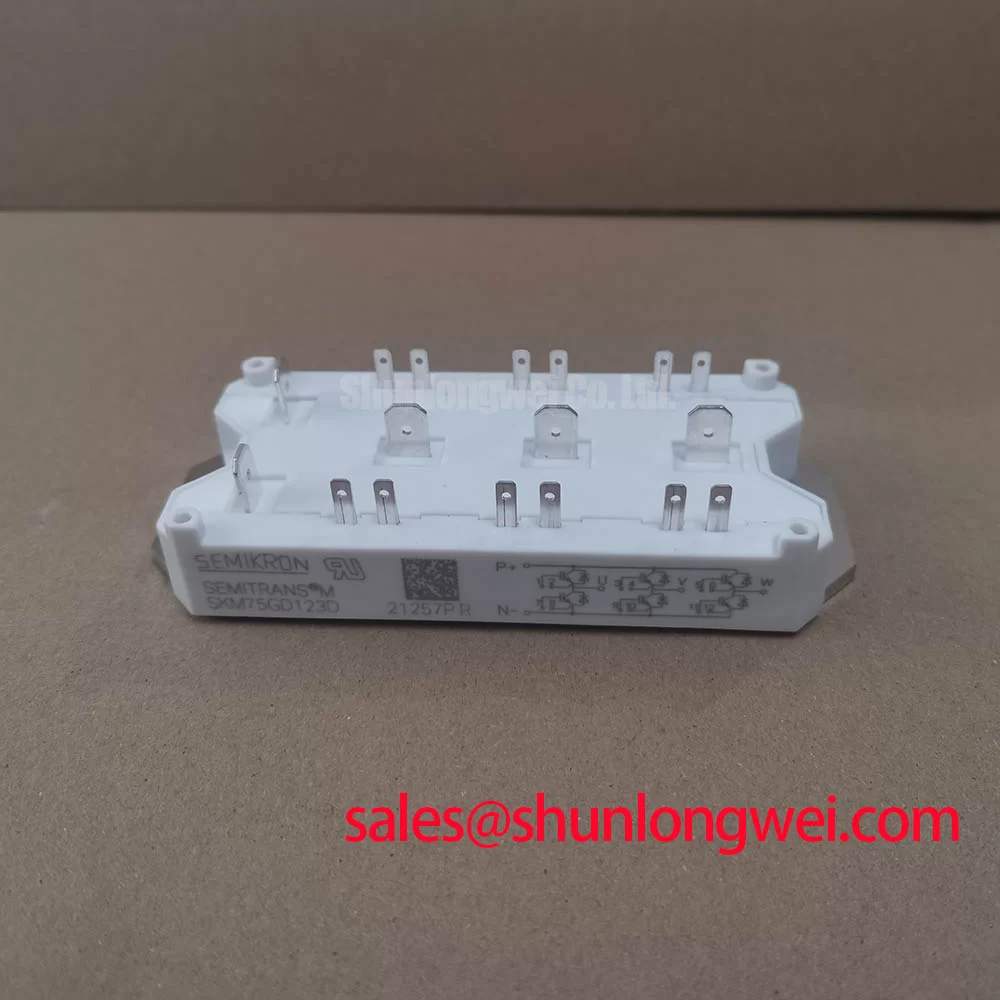

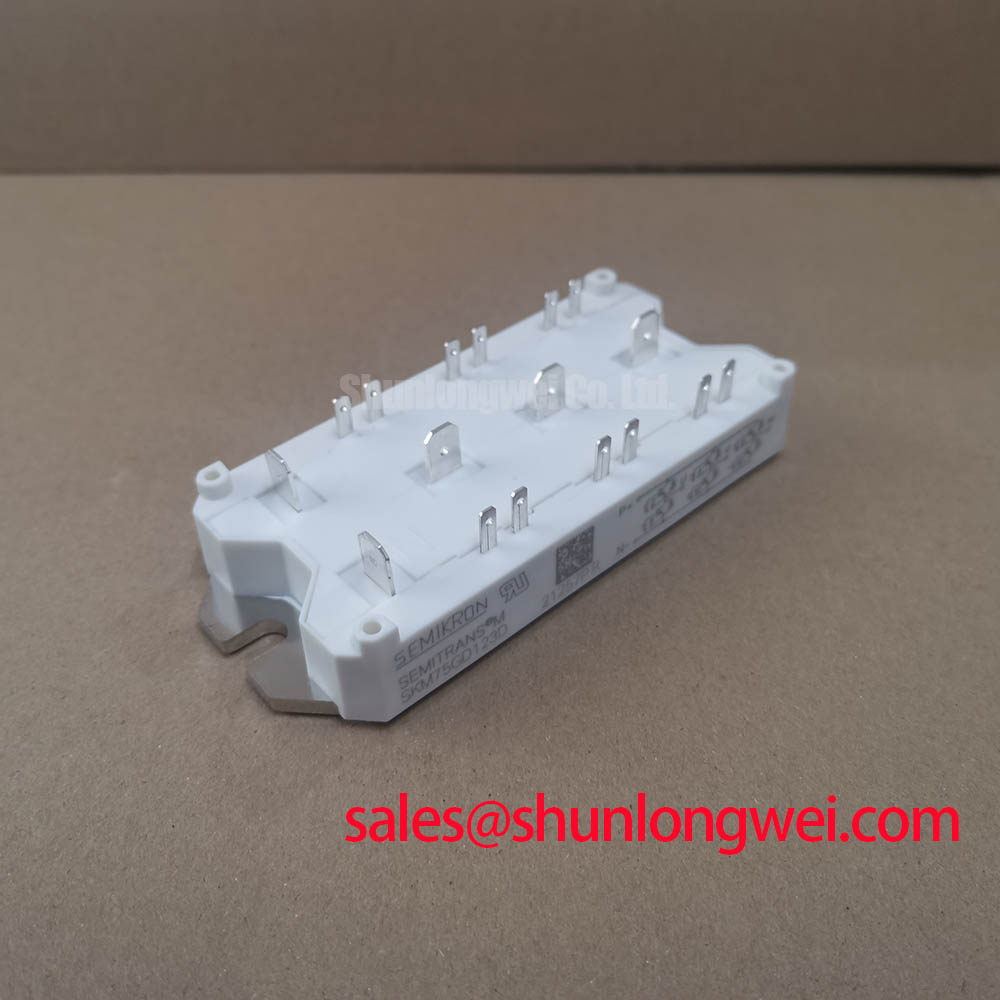

SKM75GD123D | SEMITRANS 2 IGBT Module | 1200V 75A

An Engineering-Focused Analysis of the SEMITRANS 2 IGBT Module

Engineered for high-frequency power conversion, the Semikron SKM75GD123D is a half-bridge IGBT module that delivers exceptional efficiency and thermal stability for demanding industrial applications. This module integrates advanced Trench Fieldstop IGBT 3 and CAL 3 diode technology to provide a robust solution for system designers. Core specifications include: 1200V | 75A (Nominal) | VCE(sat) of 2.05V (typ. at 125°C). The key engineering benefits are significantly reduced switching losses and superior thermal performance. This module directly addresses the challenge of balancing efficiency and power density in modern inverter designs. For industrial motor drives requiring lower conduction losses at high operational temperatures, the SKM75GD123D's low VCE(sat) makes it a strategically sound choice.

Key Parameter Overview

Decoding the Specs for Enhanced Switching Performance

The technical specifications of the SKM75GD123D are foundational to its performance in high-frequency switching circuits. The parameters listed below have been selected to highlight the module's efficiency and robustness, which are critical for an accurate system-level evaluation.

| Parameter | Symbol | Value | Conditions |

|---|---|---|---|

| Collector-Emitter Voltage | Vces | 1200 V | Tj = 25 °C |

| Collector-Emitter Saturation Voltage | VCE(sat) | 2.05 V (typ.) | IC = 75 A, Tj = 125 °C, Vge = 15 V |

| Nominal Collector Current | IC,nom | 75 A | Tc = 80 °C |

| Maximum Continuous Collector Current | IC | 105 A | Tc = 25 °C |

| Thermal Resistance, Junction to Case | Rth(j-c) | 0.24 K/W | Per IGBT |

| Turn-On Switching Energy | Eon | 11.5 mJ (typ.) | IC = 75 A, Tj = 125 °C |

| Turn-Off Switching Energy | Eoff | 15 mJ (typ.) | IC = 75 A, Tj = 125 °C |

| Short Circuit Withstand Time | tsc | 10 µs | Vcc = 800 V, Vge ≤ 15 V, Tj = 150 °C |

Download the SKM75GD123D datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Achieving System-Level Benefits in Industrial Power Conversion

The SKM75GD123D is optimized for power conversion systems where efficiency and reliability are paramount. Its primary application is in industrial Variable Frequency Drives (VFDs), which control the speed of AC electric motors. In a typical VFD design, engineers face the challenge of managing heat generated by the power stage, especially within compact, enclosed cabinets. The SKM75GD123D's low VCE(sat) of 2.05V at a nominal 75A and 125°C directly reduces conduction losses—the primary source of heat during operation. Think of VCE(sat) as the electrical "friction" of the switch; a lower value means less energy is wasted as heat. This allows engineers to design systems with smaller, more cost-effective heatsinks or to operate at higher power levels without thermal throttling, directly contributing to a higher power density and lower total cost of ownership. Its robust 1200V rating provides a substantial safety margin for systems operating on 400V or 480V industrial lines.

Beyond VFDs, this module is also well-suited for Uninterruptible Power Supplies (UPS), solar inverters, and welding power supplies. While the SKM75GD123D is ideal for mid-power applications, for systems demanding higher current capabilities, the related SKM150GB123D offers a higher current rating within a compatible package family.

Technical Deep Dive

An Analysis of Trench Fieldstop IGBT 3 and CAL Diode Technology

The performance of the SKM75GD123D is rooted in Semikron's third-generation Trench Fieldstop (FS) IGBT technology. Unlike older planar IGBT structures, the Trench Gate design creates a vertical current path that significantly increases the density of charge carriers. This architectural change is the primary reason for the device's low collector-emitter saturation voltage (VCE(sat)), which minimizes conduction losses. The "Fieldstop" layer, a crucial addition, allows for a much thinner N-drift region. This thinning reduces switching losses (Eon and Eoff) because less charge needs to be moved during turn-on and turn-off transitions. The combination results in a device that is both efficient during the 'on' state and fast to switch, a critical balance for modern PWM-controlled inverters.

Complementing the IGBT is the CAL 3 (Controlled Axial Lifetime) free-wheeling diode. This diode is engineered for soft recovery characteristics. A "soft" recovery means the diode turns off smoothly without causing abrupt voltage spikes or oscillations. This behavior is crucial for reducing electromagnetic interference (EMI) and improving the reliability of the entire system, as it places less stress on the IGBTs and other circuit components. What is the primary benefit of its CAL 3 diode? Minimized voltage overshoots and reduced EMI generation.

Industry Insights & Strategic Advantage

Meeting the Demands for Higher Efficiency and Power Density

The industrial sector is under continuous pressure to improve energy efficiency, driven by regulations and the rising cost of energy. The SKM75GD123D directly supports these initiatives. Its high-efficiency operation, enabled by Trench Fieldstop technology, allows motor drive systems to meet stringent standards like IE3 and IE4 for motor efficiency. Lower energy losses in the inverter translate directly to reduced electricity consumption over the lifetime of the equipment. Furthermore, the trend towards decentralization and miniaturization in factory automation places a premium on power density. By minimizing heat dissipation, the SKM75GD123D enables the design of more compact inverters that can be integrated directly onto or near the motor, reducing cabinet space and simplifying system architecture. This module serves as a key enabling component for designers creating next-generation, high-density power solutions that are both cost-effective and compliant with evolving global energy standards.

Frequently Asked Questions (FAQ)

How does the Trench Fieldstop IGBT 3 technology in the SKM75GD123D differ from older IGBT generations?

Trench Fieldstop IGBT 3 technology provides a superior trade-off between conduction losses (VCE(sat)) and switching losses (Eon/Eoff). Compared to older non-punch-through (NPT) or planar technologies, it achieves a significantly lower on-state voltage drop for a given switching speed, leading to higher overall inverter efficiency.

What is the significance of the 0.24 K/W Rth(j-c) value for heatsink selection?

The thermal resistance from junction to case (Rth(j-c)) quantifies how effectively heat can be transferred from the active silicon chip to the module's baseplate. A lower value like 0.24 K/W indicates more efficient heat transfer. For a system designer, this means that for a given amount of power loss, the internal temperature of the IGBT will be lower, or alternatively, a smaller, less expensive heatsink can be used to maintain a safe operating temperature, directly impacting system cost and size.

Is the SKM75GD123D suitable for hard-switching applications?

Yes, it is designed for hard-switching topologies. The integrated CAL 3 diode is optimized for low switching losses and soft recovery, which are critical characteristics for mitigating voltage overshoots and EMI in hard-switched half-bridge configurations commonly found in motor drives and UPS systems.

Can the SKM75GD123D be operated in parallel to achieve higher current?

While paralleling IGBT modules is a common practice, it requires careful design considerations. The positive temperature coefficient of VCE(sat) in the SKM75GD123D helps promote current sharing between parallel modules. However, designers must ensure symmetrical gate drive layout and busbar connections to prevent current imbalance. For detailed guidance, it is essential to consult the manufacturer's application notes on IGBT Paralleling.

Strategic Considerations for System Design

Integrating the SKM75GD123D is more than a component choice; it is a strategic decision that influences the entire system's thermal architecture, power density, and long-term operating costs. By leveraging its low-loss characteristics, engineering teams can achieve competitive advantages in system size, efficiency, and reliability. The module's performance provides the technical foundation for developing next-generation industrial power converters that meet the market's evolving demands for more compact and energy-efficient solutions.