IGBT Design & Integration: Gate Drive, Thermal Management & Circuit Topologies

Designing with Insulated Gate Bipolar Transistors (IGBTs) is an exercise in balancing competing physics. For power electronics engineers, the goal is rarely maximizing a single parameter, but rather optimizing the complex interplay between switching speed, thermal dissipation, and electromagnetic compatibility (EMC).

As we push power densities higher in 2025—whether for a compact 150kW EV fast charger or a MW-scale solar inverter—the margin for error shrinks. A gate drive circuit that ignores the Miller Plateau will lead to parasitic oscillation; a heatsink design that overlooks the thermal impedance chain (Rth(j-c) + Rth(c-s)) will result in premature junction failure.

The Gate Drive: Your First Line of Defense

The gate driver is not just a switch; it is the control center for di/dt and dv/dt. In high-power applications, passive resistance tuning is no longer sufficient. Advanced designs now incorporate Active Miller Clamping to prevent false turn-on during high-speed switching events and Desaturation (DESAT) detection with response times under 2μs to protect against short circuits.

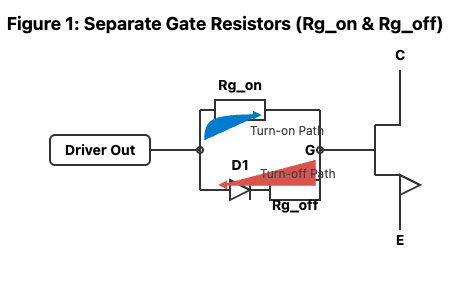

Our technical deep dive into gate drive topologies explores how negative bias rails and separated turn-on/turn-off paths can significantly reduce switching losses (Eon / Eoff) without compromising EMI performance.

Thermal Management: The Invisible Circuit

Heat is the ultimate limiter of silicon performance. Understanding the thermal stack-up—from the semiconductor die attach to the baseplate curvature—is critical. In modern modules, the shift from soldered pins to Press-Fit technology and the adoption of Phase Change Materials (PCM) for thermal interface layers are redefining reliability standards.

As highlighted in Semikron Danfoss application notes, simulating the transient thermal impedance (Zth) is essential for predicting junction temperatures during overload conditions, ensuring your design survives the peak power demands of real-world operation.

The following engineering resources dissect these critical design elements, offering schematic-level advice and thermal calculation methodologies for your next high-power project.