Content last revised on January 15, 2026

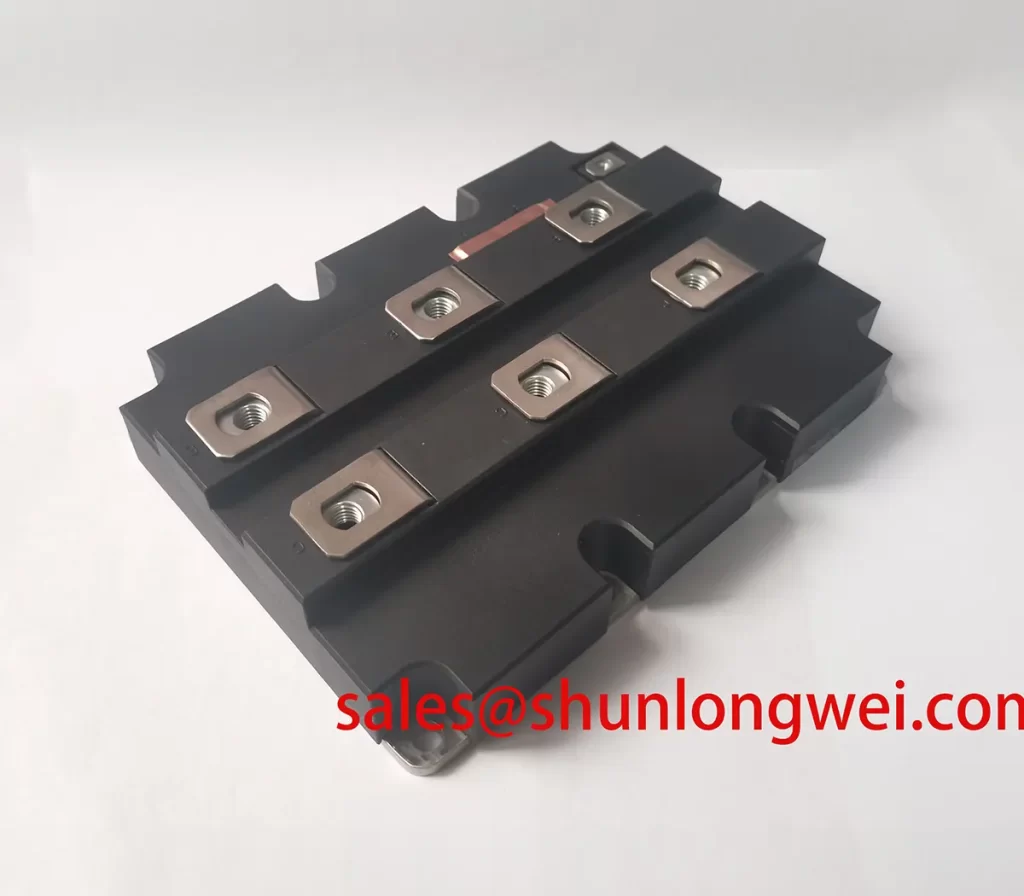

Fuji Electric 1MBI2400U4D-170 | Uncompromising Power Handling for Megawatt-Scale Systems

Key Parameters Overview

The Fuji Electric 1MBI2400U4D-170 is an IGBT module engineered for the highest echelons of power conversion. It is designed not for incremental gains but for applications where sheer power throughput and operational robustness are the primary design drivers. Below is a snapshot of its core specifications, which position it as a heavyweight solution for demanding industrial and renewable energy systems.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 1700 V |

| Continuous Collector Current (IC) @ TC=80°C | 2400 A |

| Collector-Emitter Saturation Voltage (VCE(sat)) (Typ. @ IC=2400A) | 2.30 V |

| Total Power Dissipation (PC) per IGBT | 13.0 kW |

| Thermal Resistance, Junction to Case (Rth(j-c)) per IGBT | 0.0115 °C/W |

| Chip Technology | Fuji Electric 4th Generation U-Series |

For a comprehensive list of all electrical and thermal characteristics, you can download the official Fuji Electric 1MBI2400U4D-170 datasheet.

Technical Deep-Dive: The Engineering Behind the Ratings

Understanding the 1MBI2400U4D-170 requires looking beyond the numbers to the design philosophy. Two elements are critical: the core silicon technology and the massive current rating.

- Fuji's U4-Series IGBT Technology: This module incorporates Fuji's 4th Generation "U-Series" trench gate field-stop IGBTs. While newer generations focus on reducing switching losses for higher frequency operation, the U-Series was optimized for extreme ruggedness. It boasts a wide and robust Short-Circuit Safe Operating Area (SCSOA), a critical feature in multi-megawatt systems where fault currents can be catastrophic. This represents a deliberate engineering trade-off: prioritizing survivability and reliability in harsh electrical environments.

- 2400A / 1700V Power Class: This combination of current and voltage elevates the module into a specialized class. The 1700V breakdown voltage provides a significant design margin for systems operating on a 1000V or 1100V DC bus, which is common in large-scale solar and wind applications. The 2400A continuous current rating allows designers to create extremely power-dense inverters, reducing the need for complex paralleling of multiple smaller modules.

Application Scenarios & Engineering Value

The specifications of the Fuji Electric 1MBI2400U4D-170 make it an ideal choice for a specific set of high-power applications where failure is not an option.

- Wind Turbine Converters: In multi-megawatt wind turbines, the module's high current capability is perfectly suited for the demanding role of grid-side inverters in multi-megawatt wind turbines. Its robust U4 silicon can withstand the voltage fluctuations and load variations inherent in converting variable wind energy into stable grid power.

- Heavy Industrial Motor Drives: Applications like mining excavators, steel rolling mills, and marine propulsion systems require immense, reliable power to drive large motors. The 1MBI2400U4D-170 delivers the raw current needed for high-torque motor control and is built to survive the demanding industrial environment.

- Grid-Scale Energy Storage & STATCOMs: For battery energy storage systems (BESS) and static synchronous compensators (STATCOMs) that stabilize the grid, this module provides the high-power, bidirectional switching core. Its proven reliability is essential for maintaining grid stability and power quality.

Strategic Advantage in a High-Tech World

In an industry increasingly focused on the latest wide-bandgap materials, it's easy to overlook the critical role of components like the 1MBI2400U4D-170. This module represents a "fit-for-purpose" design strategy. For applications operating below 10-15 kHz, the conduction losses are the dominant factor, and the VCE(sat) of this module is highly competitive. It delivers immense power handling in a proven package, offering a robust and cost-effective alternative to more exotic solutions. It’s a testament to the enduring value of proven silicon IGBTs for the backbone of our energy infrastructure.

Frequently Asked Engineering Questions (FAQ)

What are the critical thermal management considerations for a 2400A IGBT module?

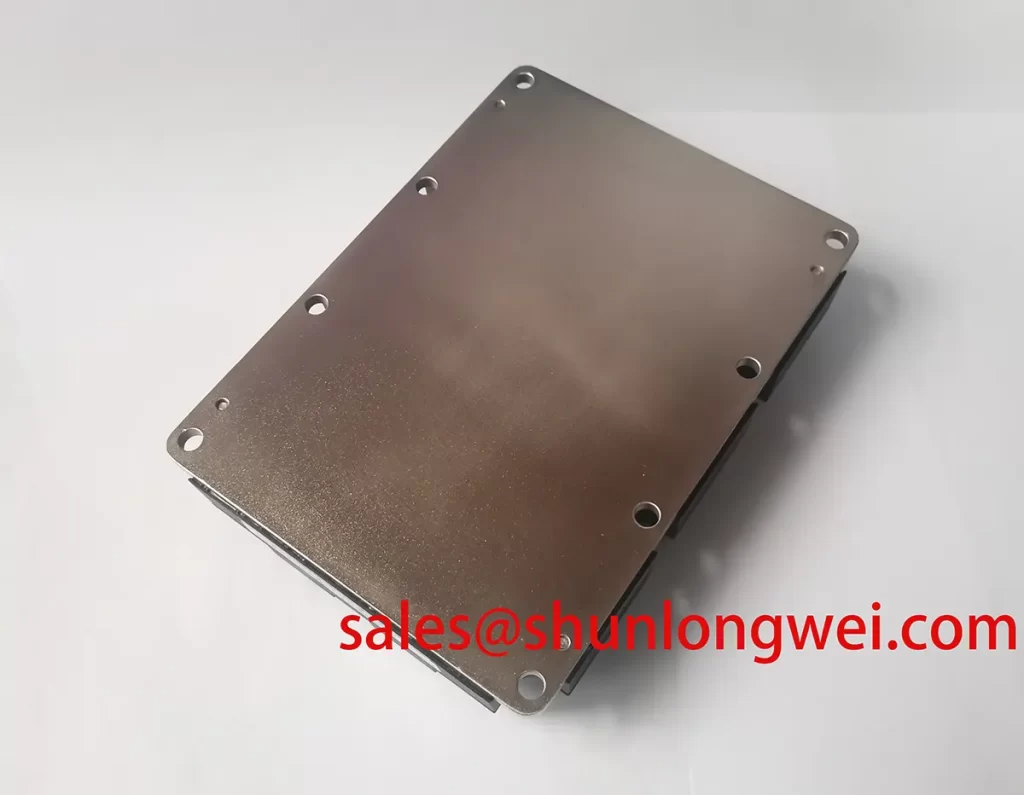

With a power dissipation capability of 13kW, thermal management is paramount. The module's low thermal resistance (Rth(j-c)) is a strong starting point, but effective heat extraction is key. This typically necessitates high-performance liquid cooling systems. Engineers must also ensure precise and even mounting pressure across the module's baseplate to guarantee optimal thermal contact with the heatsink.

Is this module suitable for high-frequency switching applications?

The 1MBI2400U4D-170 is optimized for low- to medium-frequency applications (typically < 5 kHz), such as grid-tied converters and large motor drives. While it can switch faster, its switching losses (Eon/Eoff) will become the dominant source of heat generation at higher frequencies, reducing the usable current. For applications requiring higher frequencies, designers should consider modules based on newer generation IGBTs or SiC technology.

For detailed application support or to discuss how the 1MBI2400U4D-170 can fit into your high-power design, please contact our technical team for an in-depth consultation.