Content last revised on February 1, 2026

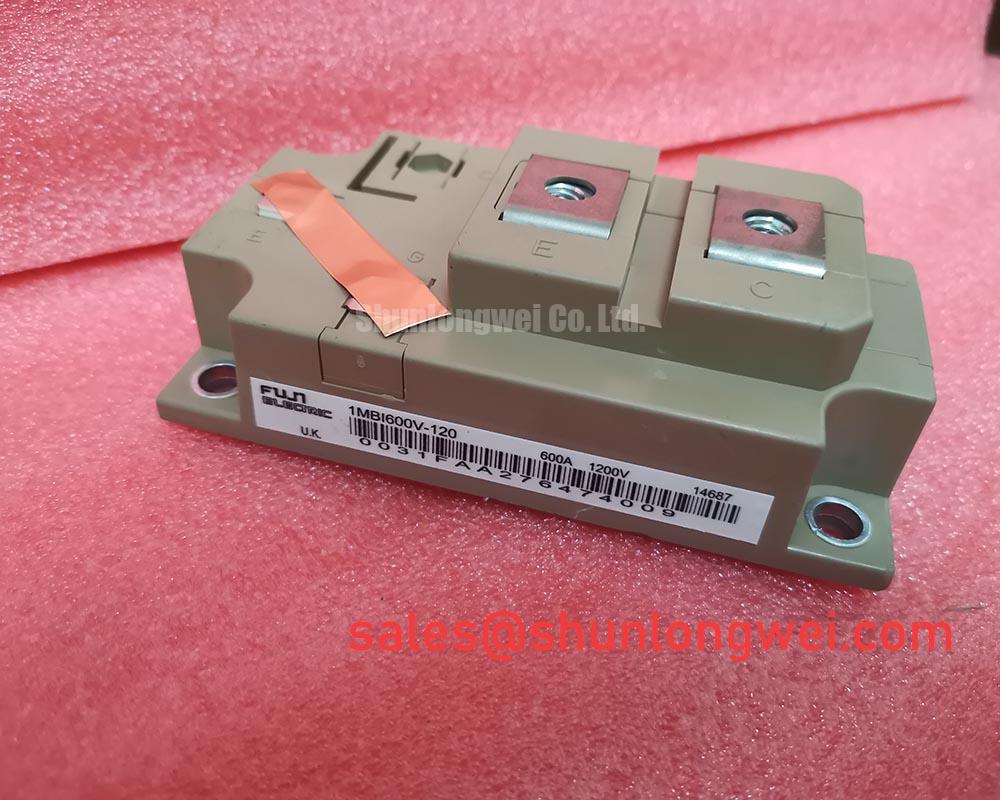

Fuji Electric 1MBI600V-120 V-Series IGBT Module

Engineered for High-Power Conversion with Superior Thermal Efficiency

The Fuji Electric 1MBI600V-120 is a high-power single IGBT module designed to provide a robust and efficient switching solution for demanding industrial applications. This V-Series module combines a high current rating with low thermal resistance, enabling simplified thermal management and enhanced system reliability. Key specifications include: 1200V | 600A | Rth(j-c) 0.042°C/W. It offers the core benefits of high power density and excellent fault tolerance. For engineers designing high-current converters, this module provides the headroom needed to manage overload conditions without compromising thermal stability. Best suited for high-power industrial drives and power supplies above 250kW, where its 600A capacity provides a dependable power handling foundation.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the 1MBI600V-120 are optimized for performance and durability in high-stress electrical environments. The values below are critical for system-level thermal modeling, efficiency calculation, and ensuring operational stability. This module's low thermal resistance is a key enabler for compact and reliable system design.

| Parameter | Symbol | Condition | Value |

|---|---|---|---|

| Collector-Emitter Voltage | VCES | - | 1200V |

| Continuous Collector Current | IC | TC = 80°C | 600A |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 600A, VGE = 15V | 2.2V (typ.) / 2.8V (max.) |

| Gate-Emitter Voltage | VGES | - | ±20V |

| Thermal Resistance (IGBT) | Rth(j-c) | Junction to Case | 0.042°C/W |

| Thermal Resistance (FWD) | Rth(j-c) | Junction to Case | 0.083°C/W |

| Short-Circuit Withstand Time | tsc | VCC = 600V, VGE = 15V | 10µs |

| Maximum Junction Temperature | Tj max | - | 150°C |

Download the 1MBI600V-120 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Achieving System-Level Benefits in High-Power Industrial Systems

The 1MBI600V-120 is engineered as a foundational building block for high-power conversion systems where efficiency and reliability are paramount. Its high current rating and robust thermal performance make it an excellent choice for a range of demanding industrial applications.

- High-Power Industrial Motor Drives: In large-scale Variable Frequency Drive (VFD) systems for conveyors, pumps, and mixers, the 600A rating provides ample capability to handle high starting torques and dynamic loads. The low VCE(sat) minimizes conduction losses, directly contributing to higher drive efficiency and reduced operational costs.

- Uninterruptible Power Supplies (UPS): For data centers and critical industrial processes, the 1MBI600V-120 ensures a reliable inverter stage. Its 10µs short-circuit withstand time provides a critical safety margin, protecting the system during downstream faults and ensuring high availability. What is the main benefit of its low thermal resistance? It allows for a more compact heatsink design, increasing the power density of the overall UPS cabinet.

- Renewable Energy Inverters: The module can be effectively utilized in the DC-AC inverter stage of large solar or wind power systems. Its efficient performance is key to maximizing energy harvest, while its robust build ensures a long operational life in challenging environmental conditions.

- Welding and Induction Heating: In high-frequency welding power supplies, the fast switching characteristics of the V-Series IGBT allow for precise control of the power output, while its thermal stability ensures consistent performance during prolonged, high-duty-cycle operation.

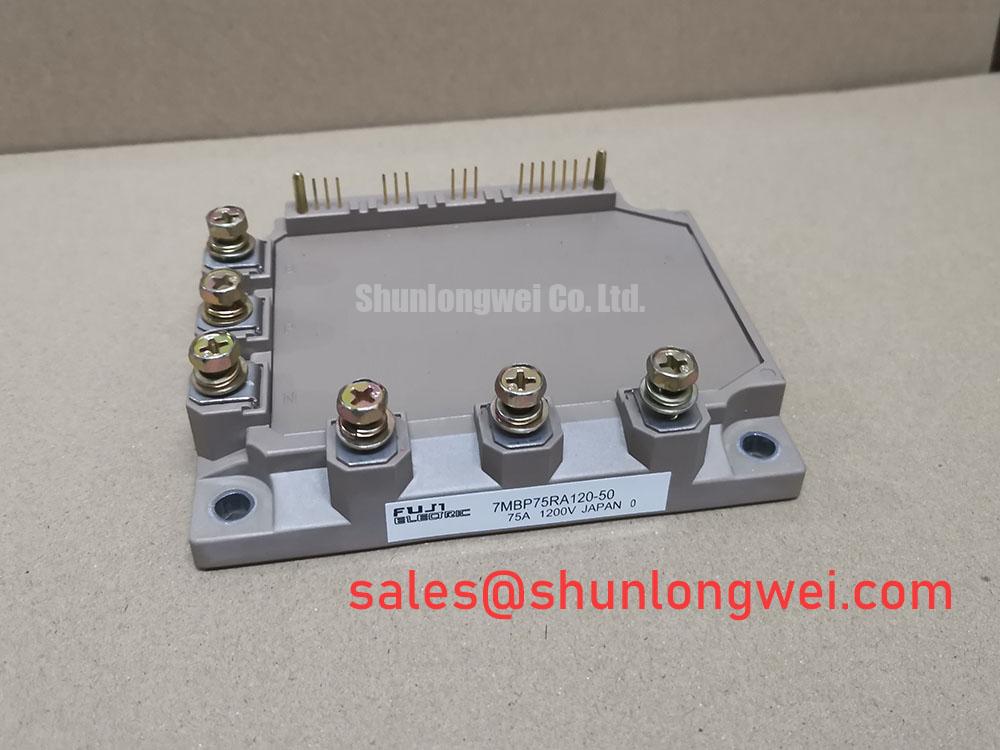

While the 1MBI600V-120 is designed for high-current single-switch topologies, for three-phase inverter designs requiring a complete bridge, a module like the 6MBI450U-120 may offer a more integrated solution.

Frequently Asked Questions (FAQ)

How does the Rth(j-c) of 0.042°C/W directly impact heatsink selection and system power density?

The thermal resistance from junction to case, Rth(j-c), acts like a bottleneck for heat transfer. A lower value signifies a more efficient path for heat to escape the semiconductor chip. With an Rth(j-c) of just 0.042°C/W, the 1MBI600V-120 allows designers to either achieve lower operating temperatures with a standard heatsink—thus increasing reliability—or use a smaller, more cost-effective heatsink while maintaining the same target temperature. This directly enables higher system power density.

What are the primary advantages of the Fuji Electric V-Series IGBT technology used in this module?

Fuji Electric's V-Series technology is engineered to optimize the trade-off between conduction losses (VCE(sat)) and switching losses. This results in higher overall inverter efficiency across a wide range of operating frequencies. The technology also focuses on high reliability and ruggedness, evidenced by the module's excellent short-circuit withstand time and power cycling capabilities.

Can the 1MBI600V-120 be used in parallel to achieve higher current ratings?

While this is a single IGBT module, paralleling multiple modules is a common practice in very high-power designs. To successfully parallel IGBTs, careful attention must be paid to gate drive circuit symmetry, busbar layout to ensure balanced current sharing, and thermal matching. The datasheet provides VCE(sat) characteristics that can be used to evaluate matching for parallel operation.

What does the single-unit (1-in-1) configuration of this module imply for circuit design?

A 1-in-1 configuration provides maximum design flexibility. It contains one IGBT switch and one anti-parallel freewheeling diode. This allows engineers to use it in various topologies, such as a single switch in a boost/buck converter, or to construct custom half-bridge, full-bridge, or multi-level inverter legs by arranging multiple modules. This contrasts with more integrated modules that might contain a fixed half-bridge or six-pack configuration.

Technical Deep Dive

A Closer Look at Thermal Management and its Impact on Reliability

The operational lifespan and reliability of a high-power module like the 1MBI600V-120 are intrinsically linked to its thermal performance. The key parameter governing this is the thermal resistance, Rth(j-c). Think of this value as the width of a highway for heat: a lower number means a wider, less congested highway, allowing heat to flow effortlessly from the active IGBT chip (the junction) to the module's baseplate (the case).

With a value of 0.042°C/W, the 1MBI600V-120 provides an exceptionally efficient thermal path. For every watt of power dissipated as heat, the IGBT junction temperature will only rise 0.042°C above the case temperature. In a system operating at 600A with a VCE(sat) of 2.2V, the conduction loss is 1320W. This low thermal resistance ensures that the immense heat generated is efficiently transferred to the heatsink, keeping the junction temperature well below the 150°C maximum limit. This thermal margin is not just a safety feature; it is a direct contributor to extending the module's power cycling capability and overall service life, especially in applications with frequent load changes like motor drives or UPS systems.

Strategic Considerations for High-Power Designs

Integrating the 1MBI600V-120 into a power system design presents a strategic opportunity to balance performance, cost, and long-term reliability. Its high-current, single-module architecture provides a simplified alternative to complex parallel arrangements of lower-current devices, reducing component count and potential points of failure. The module's superior thermal efficiency directly translates into a simplified cooling system, reducing the bill of materials and mechanical complexity. For organizations focused on total cost of ownership (TCO), investing in a module with a robust thermal design ensures higher system uptime and minimizes field service requirements, aligning with the industry-wide push for more durable and energy-efficient power infrastructure.