Content last revised on November 12, 2025

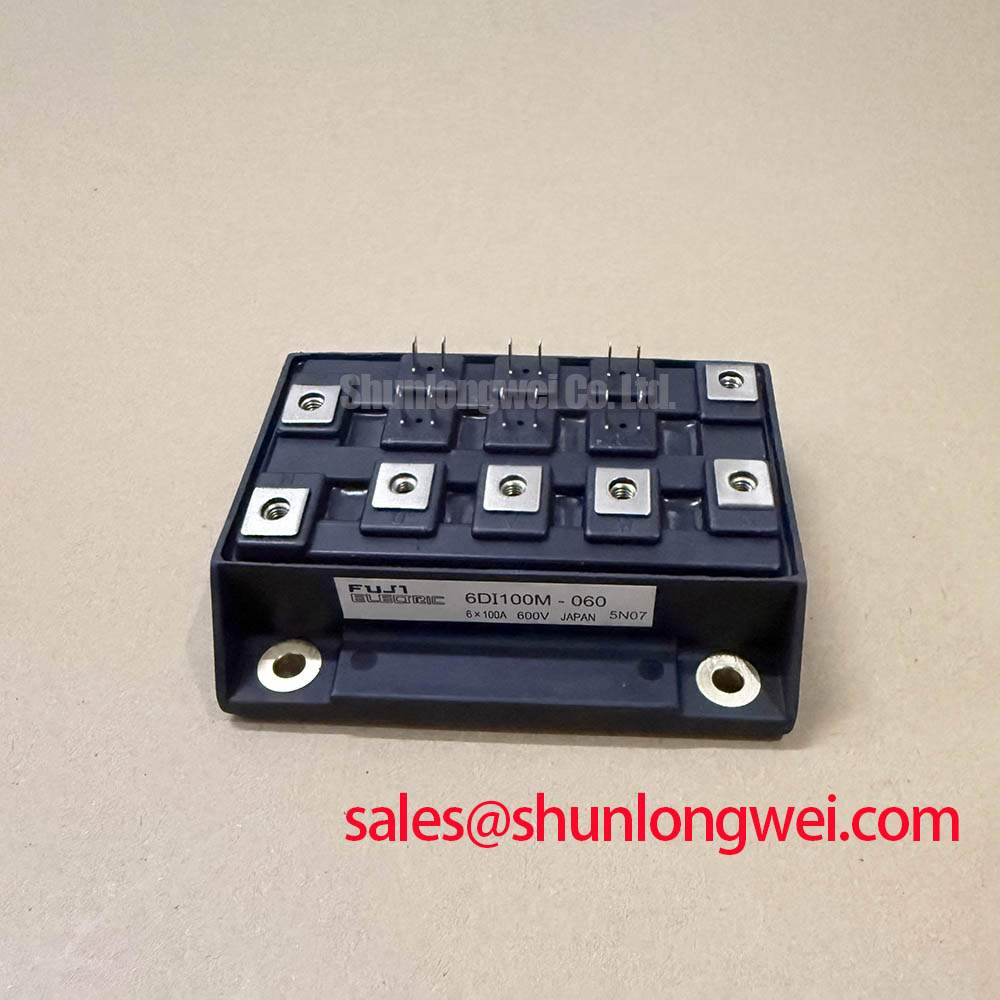

Fuji 6DI100M-060 | Compact Power Integrated Module for Motion Control

The Fuji 6DI100M-060 is an expertly engineered Power Integrated Module (PIM) designed to streamline the development of compact and reliable motor drives and power conversion systems. By co-packaging the essential power stages into a single, thermally efficient housing, this module offers a significant advantage in applications where space, assembly cost, and system reliability are critical design drivers. It is a workhorse component built for enduring performance in demanding industrial environments.

Product Highlights

The 6DI100M-060 moves beyond discrete components by offering a true system-in-a-package solution. This integration is key to its value proposition:

- Complete Power Stage Integration: Features a three-phase converter (diode bridge), a three-phase inverter (6-pack IGBT), and a chopper IGBT for dynamic braking.

- Optimized for Motion Control: The 100A, 600V rating is ideally suited for low- to medium-power AC motor drives, servo amplifiers, and general-purpose inverters.

- Enhanced Reliability: A simplified power layout with fewer interconnects reduces parasitic inductance and potential points of failure, contributing to a more robust final product.

- Integrated NTC Thermistor: Allows for direct monitoring of the module's substrate temperature, providing a critical feedback loop for over-temperature protection.

Key Parameter Overview

Engineers require quick access to critical data. The table below summarizes the core electrical and thermal specifications for the Fuji 6DI100M-060. For a complete breakdown of characteristics and performance curves, you can download the full datasheet here.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 600V |

| Continuous Collector Current (IC) | 100A (@ Tc=25°C, per IGBT) |

| Collector-Emitter Saturation Voltage (VCE(sat)) | 2.7V (Max) |

| Integrated Components | 3-Phase Rectifier, 3-Phase Inverter, Brake Chopper, NTC Thermistor |

| Short-Circuit Withstand Time (tsc) | > 10µs |

| Package Type | Fuji M631 |

Application Scenarios & Value Proposition

The true value of the Fuji 6DI100M-060 lies in how its integrated design solves specific engineering challenges across various applications:

- Variable Frequency Drives (VFDs): The PIM architecture drastically reduces the footprint of the power stage. By combining the AC-DC converter and DC-AC inverter, it simplifies the PCB layout, minimizes assembly time, and lowers the overall Bill of Materials (BOM) cost.

- Servo Amplifiers: In high-precision robotics and CNC machinery, the integrated brake chopper is invaluable. It provides a built-in, efficient path to dissipate regenerative energy during motor deceleration, protecting the DC bus from overvoltage conditions and improving dynamic performance. This is a core part of powering precision servo drives.

- Uninterruptible Power Supplies (UPS): Reliability is non-negotiable in UPS systems. A factory-tested, integrated Power Integrated Module like the 6DI100M-060 offers higher dependability compared to a discrete solution with numerous solder joints and connections.

Technical Deep Dive: Robustness and Integration

Two engineering features set the 6DI100M-060 apart for its target applications. First, its robust short-circuit withstand time (tsc) of over 10 microseconds is a critical safety feature. In motor drive applications, events like a phase-to-phase short or a locked rotor can cause immense current flow. This 10µs rating provides a crucial window for the gate drive protection circuitry to detect the fault and execute a safe shutdown, preventing catastrophic module failure. Understanding these mechanisms is key to preventing common IGBT failures.

Second, the PIM design inherently minimizes stray inductance between the rectifier's DC output and the inverter's DC input. This physical proximity, impossible to achieve with discrete components spread across a PCB, reduces voltage overshoot on the IGBTs during high-speed switching. The result is lower component stress, improved EMC performance, and enhanced system reliability.

Frequently Asked Questions (FAQ)

1. What are the primary thermal management considerations for the 6DI100M-060?

Because the module houses rectifier diodes, IGBTs, and FWDs, all generating heat on a single isolated baseplate, effective thermal management is crucial. A single, flat heatsink with a high-quality Thermal Interface Material (TIM) is required. Ensure adequate mounting pressure is applied evenly across the module to achieve the specified thermal resistance and prevent localized hot spots.

2. Is a negative gate voltage necessary for turning off the IGBTs in this module?

While the IGBTs can be turned off with a 0V gate signal, using a negative gate voltage (e.g., -5V to -10V) is highly recommended, especially in electrically noisy motor drive environments. A negative bias provides a stronger "off" state, significantly improving immunity to dV/dt-induced parasitic turn-on (the Miller effect) and ensuring more reliable switching performance.

For detailed selection advice or to discuss how the Fuji 6DI100M-060 fits into your specific power design, please contact our technical team for expert consultation.