Content last revised on December 1, 2025

6MBP75VBA060-50: A Fuji Electric V-Series IPM for High-Reliability Power Systems

An Engineer's Introduction to the 6MBP75VBA060-50 IPM

Integrating Advanced Protection and a Full Inverter Stage

The Fuji Electric 6MBP75VBA060-50 is a V-Series Intelligent Power Module (IPM) that delivers a robust, highly integrated solution for three-phase motor control and inverter applications. What is the primary benefit of its integrated design? Enhanced long-term reliability by consolidating complex circuitry and protection functions. This module integrates a 600V / 75A six-pack IGBT array with optimized gate drivers and a full suite of protection features, including a crucial over-temperature sensor that directly monitors the IGBT junction temperature. This level of integration simplifies the design process and improves operational ruggedness. For motor drives and inverters up to approximately 30kW requiring high reliability under demanding load conditions, this IPM presents a compelling engineering choice.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The specifications of the 6MBP75VBA060-50 are tailored for high-performance motion control and inverter systems. The parameters below highlight its capacity for robust and reliable operation, a direct result of its intelligent, integrated design.

| Electrical Characteristics (Tj=25°C, VCC=15V unless otherwise specified) | |||

|---|---|---|---|

| Inverter Section | |||

| Collector-Emitter Voltage (Vces) | Maximum rating for blocking voltage. | 600V | Suitable for 200-240V AC line applications. |

| Collector Current (Ic) | Continuous DC current capability. | 75A | Supports medium-power motor drives. |

| Collector-Emitter Saturation Voltage (Vce(sat)) | Typical voltage drop during conduction. | 2.2V (typ.), 2.7V (max.) | Low value indicates reduced conduction losses. |

| Control & Protection Section | |||

| Control Supply Voltage (Vcc) | Operating voltage for internal logic and drivers. | 13.5V (min) to 16.5V (max) | Standard logic level supply. |

| Over-Temperature Protection (TjOH) | Directly sensed IGBT junction temperature trip level. | 150°C (typ.) | Provides rapid, accurate overheating shutdown. |

| Short Circuit Protection Voltage (Vsc) | DC-link voltage range for valid SC protection. | Up to 400V | Ensures robust fault handling in target systems. |

Download the 6MBP75VBA060-50 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Achieving System-Level Benefits in Precision Motion Control

The 6MBP75VBA060-50 is engineered for applications where reliability and design simplification are paramount. Its feature set makes it an excellent fit for modern Servo Drives, general-purpose inverters, and commercial air conditioner compressors.

Consider a high-precision CNC milling machine's servo drive. The drive must execute rapid acceleration and deceleration cycles, leading to fluctuating load currents and significant thermal stress on the power stage. Using a discrete solution requires careful design of the Gate Drive, complex protection circuits, and a thermal management scheme that relies on an external NTC thermistor on the heatsink, which introduces a thermal delay. The 6MBP75VBA060-50 directly solves this challenge. Its integrated over-temperature protection monitors the IGBT junction in real-time, providing immediate shutdown during an overload event before damage can occur—a level of safety a delayed heatsink sensor cannot match. This integration not only boosts reliability but also shrinks the PCB footprint and reduces assembly complexity, accelerating the time-to-market for the final system.

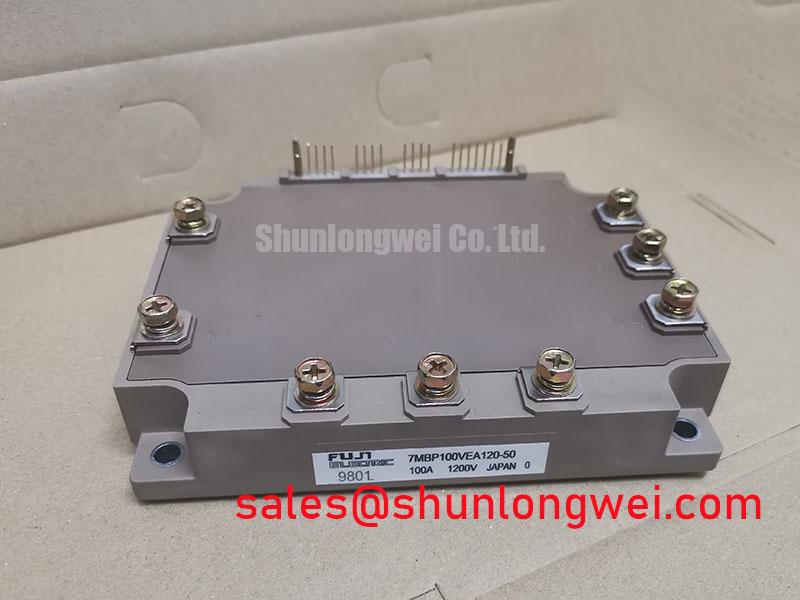

While this module is optimized for 600V systems, for applications requiring operation on higher voltage industrial lines, the related 7MBR75VB120-50 offers a 1200V rating in a similar functional package.

Technical Deep Dive

A Closer Look at the IPM's Integrated Reliability Features

The core value of an Intelligent Power Module (IPM) like the 6MBP75VBA060-50 lies in its pre-validated, integrated subsystems. The "intelligence" is not just about combining parts; it's about creating a synergistic system where each component is optimized to work together.

The most critical feature is the over-temperature protection. Relying on an external NTC thermistor mounted on the heatsink is like trying to guess if an engine is overheating by touching the car's hood. The sensor is too far from the heat source and experiences significant thermal lag. In contrast, the 6MBP75VBA060-50 has its temperature sensor on the control IC, which is thermally coupled to the IGBT chips. This is like having a probe directly on the engine block, providing instantaneous and accurate temperature data. This allows the system to shut down within microseconds of a genuine thermal crisis, preventing catastrophic failure.

Furthermore, the integrated gate driver is not a generic, off-the-shelf component. It is specifically tailored by Fuji Electric for the V-Series IGBTs inside the module. This is analogous to a race car having a custom-tuned engine control unit (ECU) instead of a generic one. The drive strength, turn-on/off speeds, and dead-time are all factory-optimized to minimize switching losses and control voltage overshoots, ensuring the IGBTs operate within their safe operating area (SOA) across all conditions. This eliminates a significant source of design risk and validation effort for the power electronics engineer.

Frequently Asked Questions (FAQ)

What is the primary advantage of the 6MBP75VBA060-50's integrated temperature sensing over a traditional NTC thermistor?

The key advantage is speed and accuracy. By detecting the temperature directly at the IGBT chip level, the IPM can react to an over-temperature event almost instantly, preventing thermal runaway and catastrophic failure. A heatsink-mounted NTC thermistor has a significant delay due to the thermal resistance between the chip and the heatsink, which can be too slow to protect the device during rapid overload conditions.

Is the 6MBP75VBA060-50 suitable for both hard-switching and soft-switching topologies?

Yes. The datasheet highlights its "low power loss and soft switching" characteristics, indicating that the V-Series IGBTs and integrated FWDs are optimized for efficiency in conventional hard-switched PWM inverters. Their performance also makes them well-suited for soft-switching resonant topologies, where reduced switching losses can be further leveraged to achieve higher efficiency or operating frequencies.

Design & Engineering Considerations

To maximize the performance and longevity of the 6MBP75VBA060-50, a sound thermal management strategy is crucial. Proper mounting on a flat, clean heatsink with the correct torque (1.3 - 1.7 Nm) and an appropriate thermal interface material is essential to ensure low thermal resistance. As an integrated module, it simplifies many aspects of power stage design, but attention to DC-link capacitor layout and providing a clean control power supply (Vcc) remains critical for stable operation. For design teams looking to accelerate development and enhance system reliability in motor control applications, leveraging the built-in intelligence of this IPM offers a clear path to a more robust and compact final product.