Content last revised on November 14, 2025

BSM100GD60DLC: 600V 100A Six-Pack IGBT Module for High-Reliability Drives

Product Overview: Reliability by Design

Integrated Thermal Sensing and Robust Switching for Demanding Applications

Engineered for high-reliability motor control applications, the Infineon BSM100GD60DLC is a 600V Six-Pack IGBT Module that integrates precise thermal monitoring and robust fault protection to maximize operational uptime. It combines six IGBTs and six freewheeling diodes in a three-phase bridge configuration, offering a streamlined solution for power conversion systems. Key specifications include: 600V | 100A (Icnom) | VCE(sat) 2.2V (typ @125°C). This module provides two primary engineering benefits: enhanced system protection via an integrated NTC thermistor and superior ruggedness with a 10µs short-circuit withstand time. By embedding these features within a standard industrial package, the BSM100GD60DLC directly addresses the core challenge of building durable and efficient motor drives. For AC motor drives up to ~45kW requiring precise thermal management and high reliability, this 600V module is an optimal design choice.

Application Scenarios & Value

Delivering Uptime in High-Duty-Cycle Industrial Automation

The BSM100GD60DLC is optimized for power conversion systems where operational resilience is a primary design criterion. Its capabilities are particularly valuable in industrial applications such as Variable Frequency Drives (VFDs), servo drives for robotics, and auxiliary power converters.

Consider a high-duty cycle conveyor system in a manufacturing facility, which is prone to frequent load changes and potential overcurrent conditions. Using the BSM100GD60DLC in the system's VFD provides a distinct advantage. The integrated NTC thermistor offers real-time temperature feedback to the system controller. Instead of a sudden shutdown from an over-temperature fault, the controller can proactively reduce the motor speed or current, allowing the module to cool while maintaining operation. This prevents costly downtime and enhances equipment longevity. The module's robust short-circuit withstand time further ensures it can survive unexpected fault events, a critical requirement for meeting industrial safety standards like IEC 61800-5-1. What is the key benefit of the integrated NTC? Direct, real-time temperature monitoring for enhanced system protection.

While this model is tailored for 230/400V line applications, for systems requiring higher blocking voltage, the related BSM75GD120DN2 offers a 1200V rating.

Key Parameter Overview

Functional Specification Grouping for System Design

The following parameters define the operational boundaries and core electrical characteristics of the BSM100GD60DLC. The data is structured to support key design stages, from power stage dimensioning to thermal system validation.

| Maximum Ratings (Tvj = 25°C unless otherwise specified) | |

|---|---|

| Collector-Emitter Voltage (VCES) | 600 V |

| Continuous DC Collector Current (IC) | 130 A (@ TC = 25°C) / 100 A (@ TC = 80°C) |

| Total Power Dissipation (Ptot) | 430 W (@ TC = 25°C) |

| Gate-Emitter Voltage (VGES) | ±20 V |

| Electrical Characteristics (Tvj = 125°C unless otherwise specified) | |

| Collector-Emitter Saturation Voltage (VCEsat) | 2.2 V (typ. @ IC = 100 A, VGE = 15 V) |

| Diode Forward Voltage (VF) | 2.0 V (typ. @ IF = 100 A, VGE = 0 V) |

| Short Circuit Withstand Time (tsc) | 10 µs (VCC = 360 V, VGE ≤ 15 V) |

| Thermal and NTC Characteristics | |

| Thermal Resistance, Junction-to-Case (Rth(j-c)) | 0.29 K/W (per IGBT) / 0.48 K/W (per Diode) |

| NTC Resistance (R25) | 5 kΩ (T = 25°C) |

This table presents a selection of key parameters. For comprehensive electrical and thermal characteristics, performance curves, and application notes, it is essential to consult the official documentation.

Download the BSM100GD60DLC datasheet for detailed specifications and performance curves.

Technical Deep Dive

The Engineering Value of Integrated Protection Features

The true value of the BSM100GD60DLC extends beyond its core voltage and current ratings. Its design incorporates features that directly enhance the reliability and safety of the end application. The integrated NTC thermistor acts as a built-in fever thermometer for the module. By providing a direct, analog measurement of the module's internal temperature, it allows for far more sophisticated thermal management than external heatsink sensors can offer. This enables features like predictive maintenance alerts and controlled power derating, maximizing system availability.

Furthermore, the 10µs short-circuit withstand time is a critical safety feature. What defines its fault tolerance? A robust 10µs short-circuit withstand time. This rating can be thought of like a vehicle's airbag system; it is a non-negotiable safety mechanism designed to protect the system during a catastrophic failure event, like a motor winding short. This specified duration gives the gate drive protection circuitry sufficient time to detect the fault and safely turn off the IGBT, preventing module rupture and protecting upstream components. This ruggedness is a cornerstone of designing reliable power electronics for harsh industrial environments.

Frequently Asked Questions (FAQ)

How does the BSM100GD60DLC's integrated NTC thermistor improve system reliability over an external sensor?

The integrated NTC is located much closer to the IGBT and diode chips inside the module, providing a more accurate and timely reading of the actual semiconductor junction temperature. This minimizes thermal lag, allowing the control system to react faster to potential overheating events. An external sensor on the heatsink can only measure a delayed, dampened temperature, potentially allowing the junctions to exceed their safe operating limits before a fault is detected.

What is the practical impact of the 2.2V typical VCE(sat) on heatsink design and operational cost?

A lower collector-emitter saturation voltage (VCE(sat)) directly reduces conduction losses, which is the power dissipated as heat when the IGBT is switched on. A lower VCE(sat) means less waste heat is generated for the same amount of current. This allows engineers to specify a smaller, more cost-effective heatsink or run the system at a lower operating temperature for the same heatsink size, which in turn increases the module's lifespan and reliability. Over time, this higher efficiency translates to lower energy consumption and reduced operational costs for the end user.

System Integration and Design Support

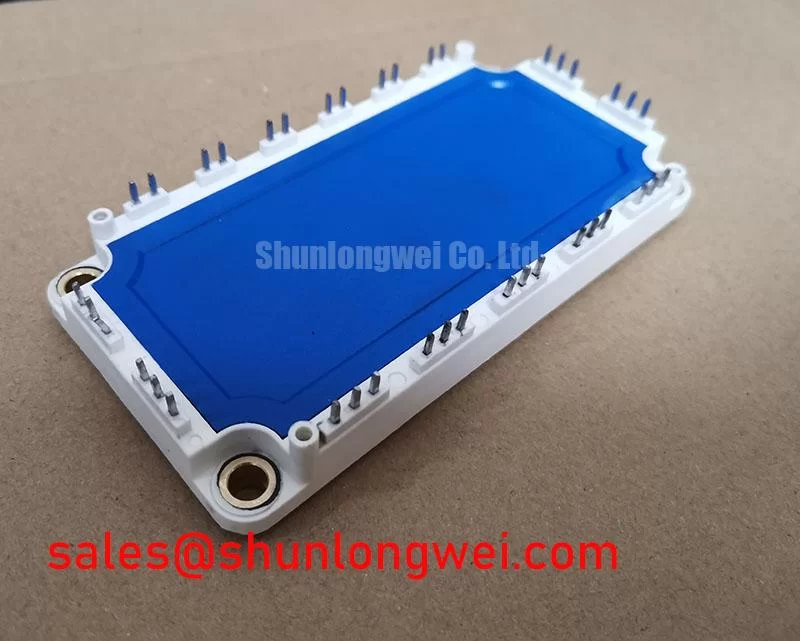

The BSM100GD60DLC is housed in the industry-standard EconoPACK 2 package, featuring screw terminals that facilitate straightforward and reliable assembly. Its integrated nature as a six-pack module simplifies the power stage layout, reducing component count and potential points of failure compared to a discrete design. For further design support, a range of resources on IGBT modules and gate driver implementation is available from manufacturers and industry experts.

To accelerate your design process and ensure optimal performance, please contact our technical support team for assistance with component selection and application review.