Content last revised on January 13, 2026

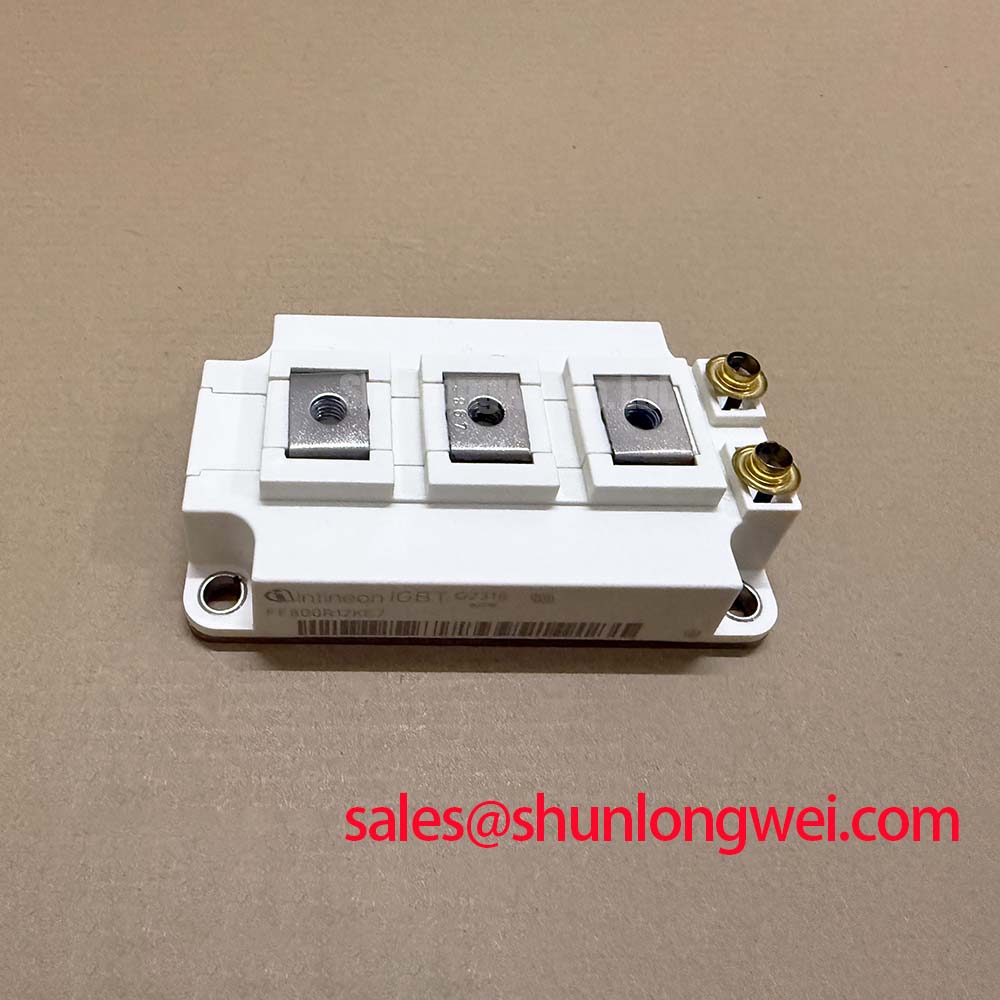

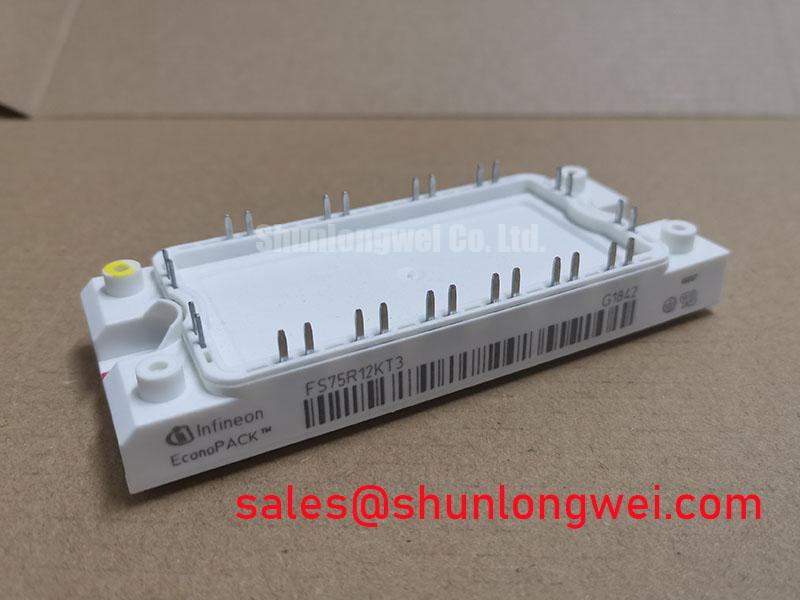

Infineon FF800R12KE7 | Robust 800A EconoDUAL™ 3 for High-Reliability Power Conversion

The Infineon FF800R12KE7 is an industry-standard 1200V, 800A IGBT module engineered for high-power applications where reliability and thermal performance are non-negotiable. Housed in the well-established EconoDUAL™ 3 package, this module leverages Infineon's mature IGBT4 Trench-Field-Stop technology and a highly efficient Emitter Controlled 4 (EC4) diode to deliver a balanced performance profile optimized for demanding industrial workloads.

Product Highlights: The Engineer's Perspective

- High Current Density: Delivers a nominal 800A in a standard industrial housing, enabling power-dense inverter designs.

- Optimized IGBT4 Chipset: Provides a well-balanced trade-off between conduction losses (VCE(sat)) and switching losses, making it ideal for applications operating in the medium frequency range (2-15 kHz).

- Soft-Switching Diode: The integrated EC4 freewheeling diode is engineered for soft switching behavior, significantly reducing voltage overshoot and electromagnetic interference (EMI). This simplifies snubber circuit design and system-level qualification.

- Superior Thermal Interface: The EconoDUAL™ 3 package features an industry-proven design with a flat baseplate, ensuring low thermal resistance to the heatsink for effective heat dissipation under heavy loads.

- Proven Reliability: Built upon a technology platform with billions of hours in field operation, the FF800R12KE7 offers a predictable and highly reliable solution for critical systems.

Technical Deep Dive: IGBT4 and EC4 Diode Synergy

The performance of the Infineon FF800R12KE7 is rooted in the synergistic combination of its core silicon components. Understanding these technologies is key to unlocking its full potential in your design.

First, the IGBT4 Trench-Field-Stop technology represents a mature and optimized generation of IGBTs. Unlike technologies hyper-focused on either minimal conduction or switching loss, IGBT4 strikes a pragmatic balance. The Trench-Field-Stop structure allows for a low VCE(sat) of 1.85V (typ. at 25°C), which minimizes heat generation during the on-state—a critical factor in high-current applications. Simultaneously, its switching characteristics are precisely controlled to manage dV/dt and di/dt, preventing the extreme EMI challenges often seen with ultra-fast devices. For more information on IGBT technology, explore our guide on the hybrid structure of IGBTs.

Second, the Emitter Controlled 4 (EC4) diode is not merely a standard freewheeling diode. It is specifically co-designed to work with the IGBT4 chip. Its key benefit is "softness"—a low reverse recovery peak current (I_rrm) and a smooth tail current decay. This characteristic is crucial for reducing DC-link voltage oscillations and overshoot during turn-off, directly contributing to a wider Safe Operating Area (SOA) and improved system reliability. This inherent softness often allows designers to reduce or eliminate external snubber components, saving cost and board space.

Key Parameters Overview

The following table outlines the critical electrical and thermal specifications for the FF800R12KE7. For comprehensive data, including characteristic curves and package details, please download the official Infineon FF800R12KE7 datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (V_CES) | 1200 V |

| Continuous Collector Current (I_C nom) | 800 A (@ T_C = 80°C) |

| Collector-Emitter Saturation Voltage (V_CE(sat), typ.) | 1.85 V (@ I_C = 800 A, T_vj = 25°C) |

| Maximum Operating Junction Temperature (T_vj op) | 150 °C |

| Short Circuit Withstand Time (t_SC) | 10 µs |

| Package | EconoDUAL™ 3 |

Engineered for Demanding High-Power Applications

The robust construction and balanced performance of the FF800R12KE7 make it a first-choice component in a variety of high-power conversion systems:

- Industrial Motor Drives: In heavy-duty applications like conveyor belts, pumps, and large fan systems, the module's high current capability and excellent thermal cycling resistance ensure precise motor control and long service life. Its reliability is paramount for minimizing downtime in factory automation.

- Renewable Energy Inverters: For large-scale wind and solar power converters, the module's efficiency and proven durability are essential for maximizing energy harvest and ensuring grid stability over decades of operation.

- Uninterruptible Power Supplies (UPS): The low conduction losses contribute directly to higher operational efficiency in large data centers and industrial UPS systems, reducing cooling requirements and total cost of ownership (TCO).

- Commercial & Agricultural Vehicles (CAV): In the electrification of heavy machinery, this module provides the rugged power switching necessary for traction inverters and auxiliary power units, operating reliably in harsh thermal and mechanical environments.

Expert Q&A: Getting the Most from the FF800R12KE7

Q: What are the best practices for paralleling multiple FF800R12KE7 modules for higher power output?

A: Paralleling these high-current IGBT modules is entirely feasible but requires careful design. The positive temperature coefficient of VCE(sat) in the IGBT4 chip provides a degree of self-balancing. However, for optimal performance, you must ensure a symmetrical DC-link busbar layout to equalize stray inductances and a balanced gate drive circuit for simultaneous switching. Most importantly, ensure uniform thermal management across all modules to maintain consistent junction temperatures and prevent current hogging.

Q: How can I mitigate the risks of IGBT failure in my application?

A: The key is a robust design that respects the module's limits. This includes implementing a fast-acting gate drive protection circuit to handle short-circuits, designing an adequate heatsink to prevent exceeding the 150°C maximum junction temperature, and ensuring the DC-link voltage remains well below the 1200V breakdown rating, even with transient overshoots. For a detailed guide, see our article on preventing common modes of IGBT failure analysis.

For detailed application notes, design-in support, or to discuss your specific power requirements, please contact our technical team today.