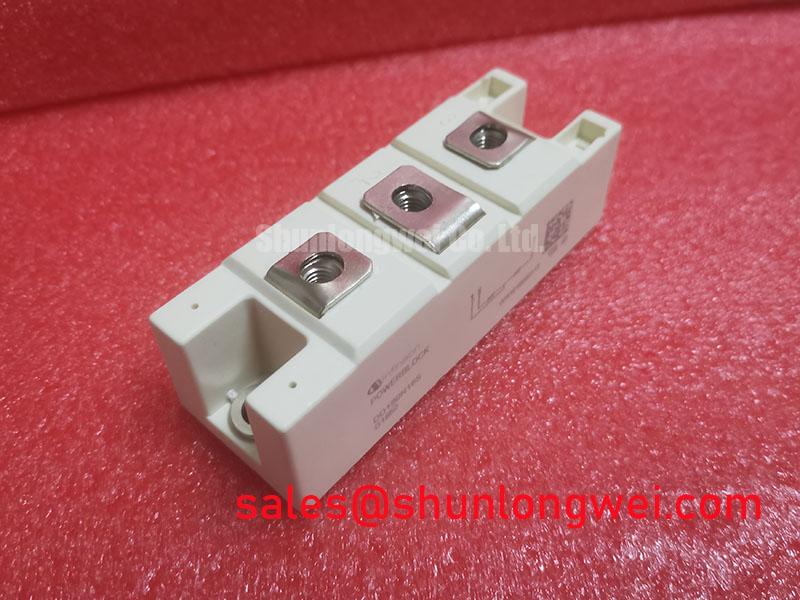

DD180N16S | 1600V Diode Module for High-Reliability Rectifiers

A Technical Overview of the Infineon DD180N16S Diode Module

Content last revised on October 19, 2025.

The Infineon DD180N16S is a high-power diode module engineered for exceptional operational lifetime and thermal stability in demanding rectifier applications. Featuring a robust 1600V blocking voltage and a 180A average forward current rating, this component leverages an advanced pressure-contact design to deliver superior performance where long-term reliability is critical. Key benefits include the complete elimination of solder-related failure modes and optimized thermal transfer for more compact system designs. This module directly addresses the engineering challenge of building resilient front-end rectifiers for high-power industrial systems operating on 690V AC lines. For industrial drives requiring robust performance on 690V grids, the DD180N16S's 1600V rating and pressure-contact build provide an optimal foundation for reliability.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal and Electrical Robustness

The specifications of the DD180N16S are tailored for high-stress industrial environments. The following table provides a functionally grouped overview of its critical performance parameters, directly sourced from the official manufacturer's documentation.

| Electrical Characteristics (per Diode) | |

|---|---|

| Repetitive Peak Reverse Voltage (V_RRM) | 1600 V |

| Average Forward Current (I_FAVM) @ Tc=100°C | 180 A |

| Surge Forward Current (I_FSM) @ 10ms, Tvj=25°C | 3300 A |

| I²t-value @ 10ms, Tvj=25°C | 54500 A²s |

| Forward Voltage (V_F) @ I_F=600A, Tvj=125°C | max. 1.55 V |

| Thermal and Mechanical Characteristics | |

| Thermal Resistance, Junction to Case (Rth(j-c)) | max. 0.150 K/W |

| Operating Junction Temperature (Tvj op) | -40 to 125 °C |

| Mounting Force (F_m) | 13 - 20 kN |

| Weight | approx. 220 g |

Download the DD180N16S datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Industrial Drives and Power Supplies

The DD180N16S is engineered for the input rectifier stages of high-power conversion systems. Its primary applications include industrial Variable Frequency Drive (VFD) systems, welding power supplies, and uninterruptible power supplies (UPS). What is the primary benefit of its pressure-contact design? Enhanced long-term reliability by eliminating solder fatigue. In a typical VFD application, the input rectifier is subjected to constant thermal cycling as the motor load changes. This thermal stress is a leading cause of failure in conventional soldered modules, as solder joints fatigue and crack over time. The DD180N16S completely circumvents this failure mechanism.

Its robust 1600V rating provides the necessary safety margin for direct connection to 690V three-phase AC lines, a common standard in heavy industrial settings. The module's high surge current (I_FSM) and I²t ratings ensure it can withstand the inrush currents associated with charging the large capacitors in a DC bus, further bolstering system resilience. For systems that demand even greater current handling capabilities, the related DD260N18KHPSA1 offers a higher current rating within a similar voltage class.

Frequently Asked Questions (FAQ)

What is the primary advantage of the pressure-contact design in the DD180N16S?

The key advantage is a significant increase in operational lifetime and reliability. By replacing soldered connections between the chip and the baseplate with a high-force mechanical clamp, it eliminates the primary wear-out mechanism in power modules: solder fatigue from thermal cycling. This results in a device that is far more resilient in applications with frequent load changes.

How does the 1600V V_RRM rating benefit system design for 690V AC lines?

A 690V AC line has a peak voltage of approximately 975V (690V * √2). Industry best practices recommend a voltage safety factor of 1.5x to 2x to account for line transients and voltage swells. The 1600V rating provides a safety margin of over 1.6x, ensuring the diodes are not stressed during normal operation and can withstand typical line disturbances, which is crucial for building a robust and reliable power system.

What are the key considerations for mounting this pressure-contact module?

Proper mounting is critical to realize the benefits of pressure-contact technology. It requires a specific, calibrated clamping force (13 - 20 kN for this model) to be applied evenly across the module's surface. This ensures both optimal electrical contact and, just as importantly, minimal Thermal Resistance to the heatsink. Using the manufacturer-specified clamps and following the prescribed torque procedures is mandatory for reliable operation.

Technical Deep Dive

A Closer Look at Pressure-Contact Technology for Long-Term Reliability

The core innovation of the DD180N16S module is its pressure-contact design, a fundamentally more robust approach to power semiconductor packaging. Unlike conventional modules where silicon dies are soldered to a Direct Bonded Copper (DBC) substrate, which is then soldered to a copper baseplate, this design eliminates the solder layers most prone to failure.

Think of the difference between glue and a high-strength bolt. Solder acts like glue; it's effective initially but can become brittle and crack after thousands of cycles of expansion and contraction (thermal cycles). The pressure-contact system acts like a precision-torqued bolt. A defined mechanical force presses the silicon die and its electrodes directly against the module's contacts and a robust, thick baseplate. This creates a stable, gas-tight electrical and thermal interface that is not susceptible to the material fatigue that plagues solder. This mechanical robustness is essential for equipment intended for a 15-20 year service life, such as in grid-tied inverters or large industrial machinery.

Engineering Support and Component Sourcing

Our team possesses the technical expertise to support engineers and procurement professionals in evaluating the DD180N16S for their specific design requirements. We provide access to comprehensive documentation and design resources to facilitate a smooth integration process. For inquiries regarding this diode module or to discuss the needs of your power conversion project, please contact our technical sales department for assistance.