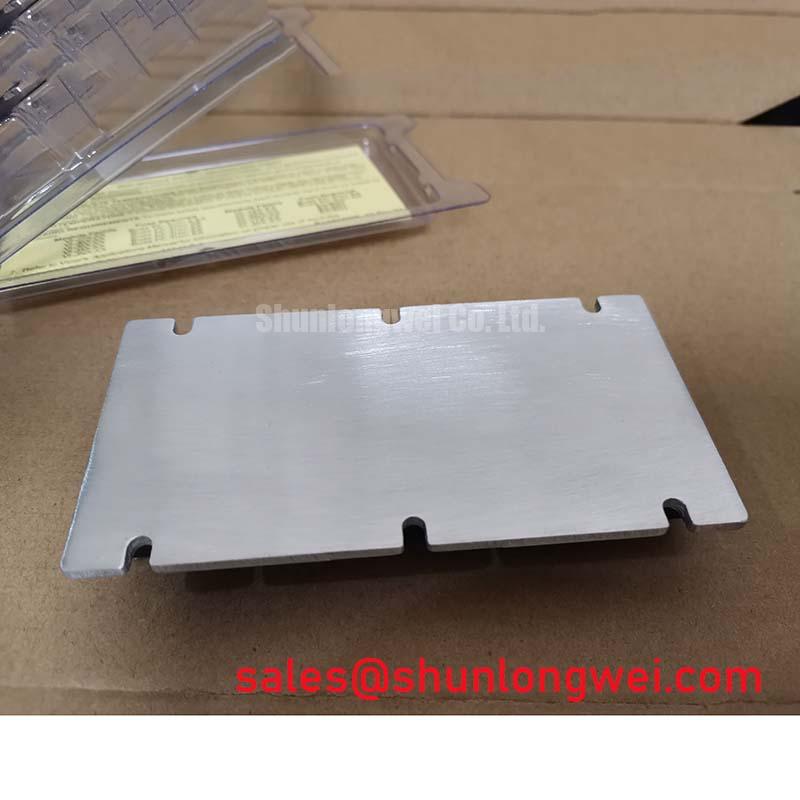

Vicor VI-260-CV DC-DC Converter | 150W Power Module

An Engineering-First Look at the VI-260-CV DC-DC Converter

The Vicor VI-260-CV is a high-density DC-DC converter module that streamlines the design of complex power architectures. It delivers robust performance from a compact, board-mountable package, integrating key functions to reduce external component requirements. With its core specifications of 100-200 VDC Input | 12V @ 12.5A Output | 80-90% Efficiency, this module offers significant design advantages. Its key benefits include accelerated system scaling and simplified power redundancy implementation. For engineers wondering how to achieve higher power outputs, the VI-260-CV directly supports parallel operation for multi-kilowatt arrays through a dedicated parallel control pin, simplifying what is often a complex design challenge.

Proven Integration in Demanding Power Systems

Hypothetical Deployment in Redundant Architectures

In critical systems like telecommunications infrastructure or industrial process controllers, power system reliability is paramount. The VI-260-CV is well-suited for N+1 redundant power schemes. By connecting multiple modules in parallel, a system can maintain continuous operation even if one module fails. The module's high power density allows this redundancy to be built into a compact space, a crucial advantage in space-constrained server racks or control cabinets. The simple connection scheme for paralleling, using the PR pin, dramatically cuts down on the design and validation time typically associated with creating fault-tolerant power systems from discrete components.

Key Parameter Overview

Defining Performance for System Design

The electrical and thermal characteristics of the VI-260-CV are foundational to its role in high-reliability systems. Understanding these parameters is key to successful integration. The module's current limiting feature, for instance, acts like a sophisticated, self-resetting fuse. It protects not only the converter but also the load it powers from potentially damaging over-current conditions, thereby enhancing the overall robustness of the end system. This built-in protection simplifies safety compliance and reduces the need for external monitoring and shutdown circuitry.

For systems that require fine-tuning of the output, the trim function allows for a ±10% adjustment from the nominal 12V output. This capability is invaluable for compensating for voltage drops in long cable runs or for precisely matching the voltage requirements of sensitive downstream electronics without needing an additional regulation stage.

For designers evaluating thermal strategies, a detailed understanding can be found in resources covering effective thermal management in power modules.

| Parameter Category | Specification | Value |

|---|---|---|

| Electrical Characteristics | Input Voltage Range | 100 - 200 VDC |

| Output Voltage (Nominal) | 12 VDC | |

| Output Power | 150 Watts | |

| Efficiency | 80-90% (Typical) | |

| Thermal Characteristics | Operating Temperature (Baseplate) | -25°C to +85°C |

| Storage Temperature | -40°C to +125°C | |

| Thermal Shutdown | +95°C (Baseplate Temperature) | |

| Control & Protection | Output Voltage Trim Range | ±10% |

| Features | Over Voltage Protection, Current Limiting, Thermal Shutdown |

Download the Datasheet for complete performance curves and specifications.

Navigating the VI-200 Series: Power and Voltage Options

Positioning the VI-260-CV within its Family

The VI-260-CV is part of Vicor's broader VI-200 family, which offers a range of power levels within the same mechanical footprint. This standardization is a core element of its design simplification value. Engineers can develop a single board layout that accommodates different power requirements by simply populating it with the appropriate module. This allows for platform-based product development, where a base design can be quickly adapted for low-, mid-, and high-power variants, significantly reducing engineering effort and time-to-market across a product line. What is the primary benefit of this family approach? It enables scalable power design without requiring a complete PCB re-layout for each power level.

Enabling Rapid Deployment in Critical Infrastructure

From Industrial Automation to Telecom Power

The VI-260-CV module is engineered for applications where reliability, power density, and design simplicity are critical evaluation factors. Its feature set makes it a strong candidate for a variety of industrial and commercial systems.

- Distributed Power Architectures: In large systems, bringing power conversion closer to the point of load improves efficiency and dynamic response. The VI-260-CV's compact size and high efficiency are ideal for these on-card converter applications.

- Industrial Control Systems: The module's wide input voltage range allows it to operate reliably from unregulated DC buses often found in factory automation environments, providing stable power for PLCs, sensors, and actuators.

- Telecommunications Equipment: With its high density and provisions for redundancy, this converter meets the stringent uptime and space requirements of telecom infrastructure, such as base stations and switching equipment.

- Automated Test Equipment (ATE): ATE systems often require multiple, isolated voltage rails. The modular nature of the VI-260-CV facilitates the rapid construction of complex, multi-output power solutions. For systems prioritizing rapid N+1 redundant power deployment on a nominal 150V bus, the VI-260-CV's integrated paralleling is the definitive choice over non-modular designs.

The Strategic Value of Modular Power Conversion

Accelerating Development Cycles with Pre-Engineered Solutions

The adoption of modular DC-DC converters like the VI-260-CV represents a strategic shift from designing power supplies with discrete components to integrating pre-certified, high-performance blocks. This approach offloads the complex tasks of magnetics design, high-frequency layout, and thermal management from the system designer to the component manufacturer. The result is a lower-risk, faster development cycle. This aligns with the broader industry trend towards faster innovation and getting products to market more quickly, where engineering resources are better spent on application-level features rather than on reinventing power conversion for every project. The transition from discrete to modular solutions is a key topic for engineers, much like the debate between an IPM vs. a discrete IGBT design in motor control applications.

Architectural Breakdown: Inside the VI-260-CV

The Technology Behind the Performance

At the core of the VI-260-CV is a high-frequency, zero-current switching (ZCS) forward converter topology. This advanced switching technique is instrumental in achieving the module's high efficiency and power density. What topology does the VI-260-CV use? It employs a proprietary ZCS forward converter architecture. Unlike conventional hard-switched converters that incur significant power loss during each switching transition, a ZCS converter times its switching events to occur when the current through the switching element is naturally at zero. This nearly eliminates switching losses, which are a major source of waste heat, especially at the high frequencies (approaching 1 MHz) used in this module. The direct engineering benefit is twofold: higher efficiency, which reduces operating costs and thermal load, and lower electromagnetic interference (EMI), which simplifies system-level filtering and compliance.

Frequently Asked Questions

Q1: Is the VI-260-CV suitable for unregulated industrial DC buses?

A1: Yes. Its wide input range of 100 VDC to 200 VDC makes it highly tolerant of the voltage fluctuations common on industrial DC buses, such as those derived from rectified 110/120 VAC lines or battery backup systems. It can provide a stable 12V output without requiring extensive upstream pre-regulation, simplifying the input power stage.

Q2: What are the primary thermal management considerations for this high-density module?

A2: Due to its high power density, effective thermal management is crucial. The module is designed for baseplate cooling. It requires a solid thermal connection to a heatsink or the system chassis to dissipate heat effectively. The datasheet provides specific thermal resistance figures, which are essential for calculating the required heatsink performance to keep the baseplate temperature below the 85°C maximum for full power operation. Proper mounting with thermal compound is non-negotiable for long-term reliability.

Your Next Steps in Power System Design

The Vicor VI-260-CV offers a proven, modular pathway to developing efficient and reliable power conversion systems. For engineers and procurement specialists looking to accelerate their design cycle and enhance system robustness, this converter provides a compelling set of integrated features. To further analyze its fit for your specific application, please review the official datasheet and contact our team for detailed technical inquiries and procurement information.