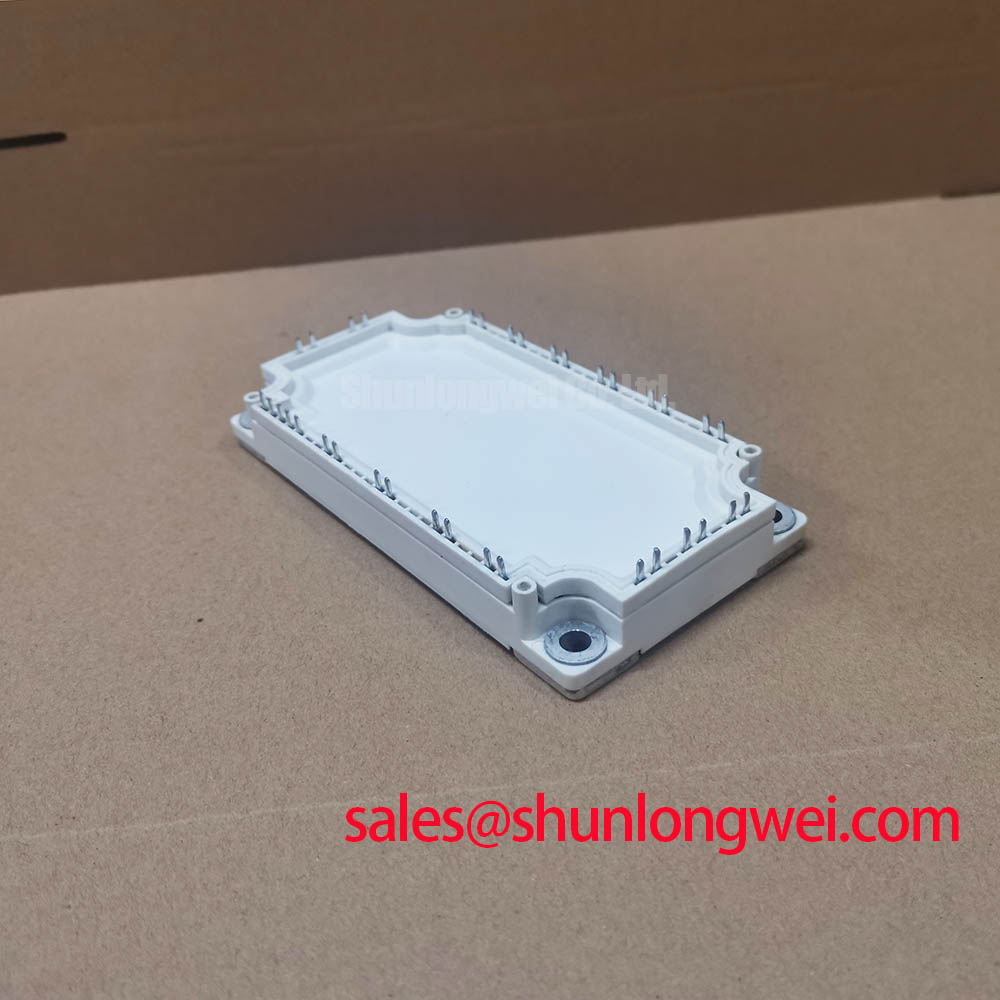

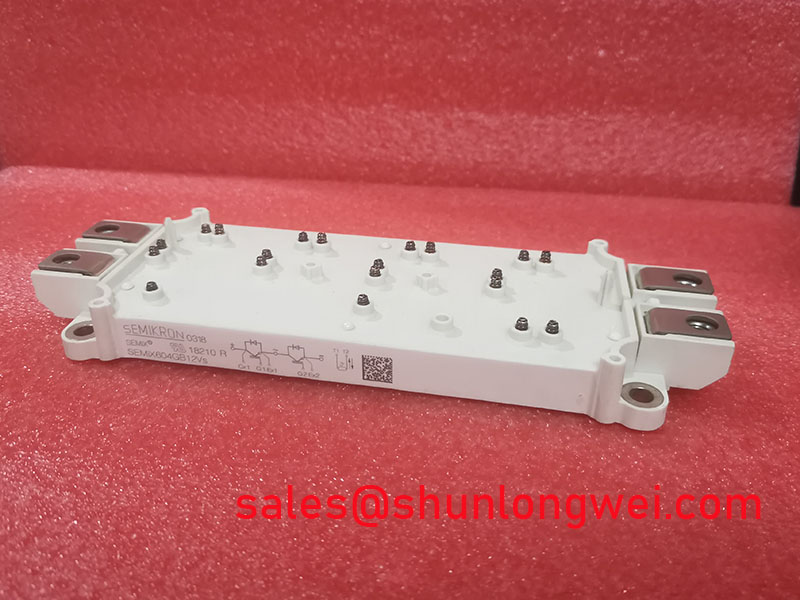

DP50H1200T101757 | Robust 1200V, 50A Half-Bridge IGBT Module for High-Reliability Power Conversion

The DP50H1200T101757 is an industry-standard half-bridge IGBT module designed for engineers who prioritize reliability and efficiency in high-power systems. It integrates two 1200V IGBTs with co-packaged freewheeling diodes (FWDs) into a compact, low-inductance package, providing a robust building block for demanding power conversion topologies.

Key Technical Specifications at a Glance

This data provides a quick reference for design engineers. For a complete characterization, including performance graphs and detailed thermal models, please consult the official datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 1200 V |

| Continuous Collector Current (IC) @ Tc=100°C | 50 A |

| Collector-Emitter Saturation Voltage (VCE(sat)), typ. @ IC=50A, Tvj=150°C | 2.1 V |

| Short-Circuit Withstand Time (tsc) | 10 µs |

| Total Power Dissipation (Ptot) @ Tc=25°C | 390 W |

| Thermal Resistance, Junction-to-Case (Rth(j-c)) per IGBT | 0.32 K/W |

| Operating Junction Temperature (Tvj op) | -40°C to +150°C |

Technical Deep Dive: Balancing Performance and Ruggedness

The DP50H1200T101757 is engineered around a proven Trench Field-Stop (TFS) IGBT technology. This architecture is not just about raw numbers; it represents a deliberate engineering trade-off. The trench gate structure allows for a higher channel density, leading to a significantly lower VCE(sat) compared to older planar technologies. This directly translates to lower conduction losses, a critical factor in applications with high duty cycles, resulting in reduced heat generation and simplified thermal management.

Simultaneously, the Field-Stop layer, combined with optimized carrier lifetime control, enables faster switching by reducing the tail current during turn-off. This minimizes switching losses (Eoff), making the module efficient even at moderate frequencies. The co-packaged FWD is specifically selected for a "soft" recovery characteristic. This soft recovery minimizes voltage overshoot and high-frequency oscillations (ringing), which in turn reduces EMI generation and voltage stress on the IGBTs, contributing to a longer system lifespan. For a more foundational understanding, explore our guide on the core structure of an IGBT.

Application Scenarios & Engineering Value

The robust design of the DP50H1200T101757 makes it a versatile workhorse for several key industrial applications:

- Variable Frequency Drives (VFDs): In motor control, the module's 10µs short-circuit withstand time provides essential protection against locked-rotor or phase-fault conditions. Its excellent thermal performance ensures stable operation under varying load profiles, from slow-speed, high-torque startups to continuous running, directly impacting the drive's reliability and uptime.

- Solar Inverters and UPS Systems: The 1200V blocking voltage offers a substantial safety margin for systems connected to 600V-800V DC buses. The low overall losses (conduction and switching) are paramount for maximizing the energy yield in a Solar Inverter and improving the battery runtime in an Uninterruptible Power Supply (UPS).

- Welding Power Supplies: The module's robust Safe Operating Area (SOA) and fast switching capabilities allow for the high-frequency pulsed power delivery required for modern welding techniques. This enables more compact magnetic components and superior arc control, leading to higher quality welds.

Engineer's FAQ for the DP50H1200T101757

What are the best practices for driving the gate of this module?

For optimal performance and reliability, a dedicated gate driver is essential. We recommend a gate voltage of +15V for a clean, fast turn-on. Crucially, a negative turn-off voltage (e.g., -8V to -15V) is highly advised. This provides a strong buffer against parasitic turn-on caused by the Miller effect (dV/dt), especially in a half-bridge configuration. Keeping the gate drive loop as short and low-inductance as possible is critical to minimizing ringing and ensuring clean switching. For more detailed strategies, review our 5 practical tips for robust gate drive design.

Can the DP50H1200T101757 be paralleled for higher power output?

Yes, paralleling is feasible, but requires careful engineering. The IGBTs within this module family typically exhibit a positive temperature coefficient for VCE(sat), which helps in balancing steady-state currents. However, dynamic current sharing during switching is dominated by layout symmetry. To successfully parallel these IGBT modules, you must ensure a symmetrical PCB layout for both the gate drive signals and the main power terminals (DC+ busbars, phase output). Any asymmetry in stray inductance will lead to unbalanced switching currents and potential failure. For complex designs or critical applications, please contact our technical team to discuss your specific requirements.