Content last revised on January 27, 2026

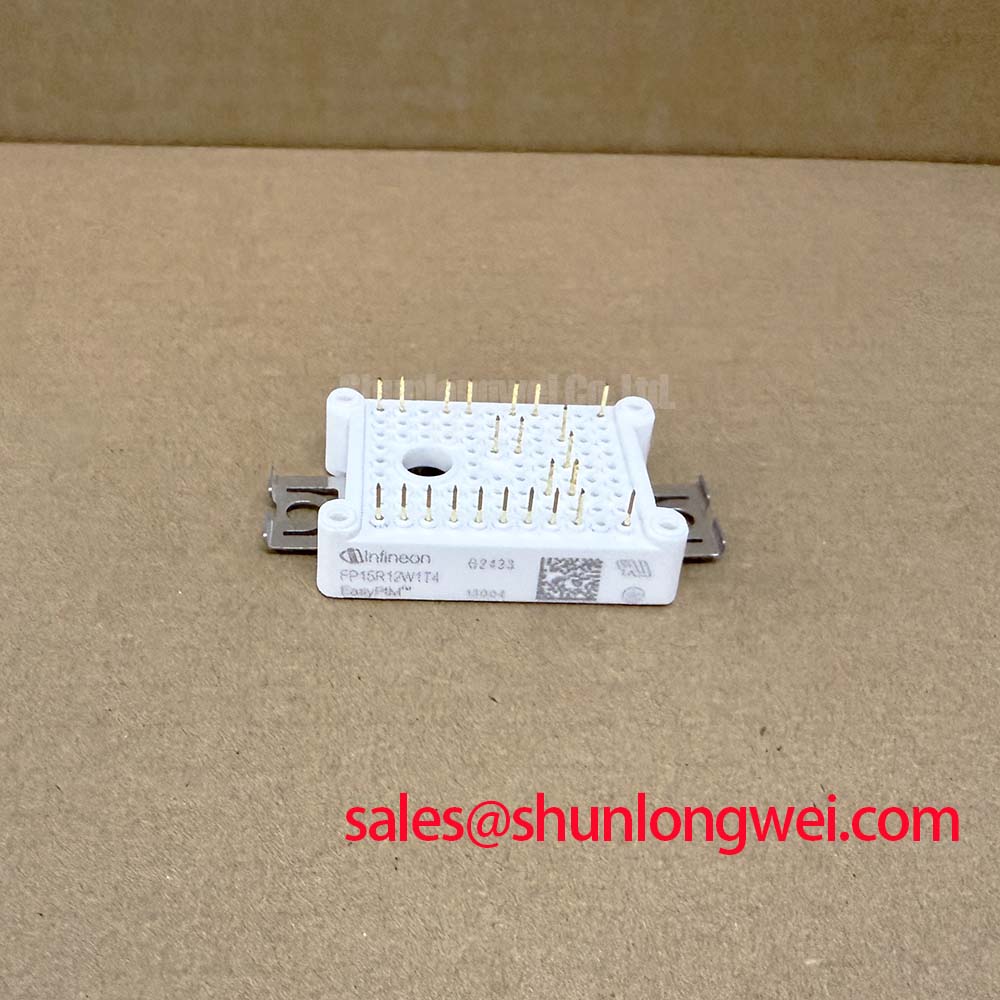

FP15R12W1T4 IGBT Module: Engineering a Compact, High-Efficiency Power Core

An In-Depth Technical Review for Power System Engineers

Key Parameter Overview

Decoding the Electrical and Thermal Specifications for Drive Design

The FP15R12W1T4 integrates multiple power stages into a single, thermally efficient package. Its specifications are tailored for low-power industrial applications where performance and space are critical design constraints. A key parameter is the low collector-emitter saturation voltage (VCE(sat)) of the inverter stage, which is typically 1.50V at its nominal current. Think of VCE(sat) as the 'friction' the switch creates when it's on. A lower value means less energy is wasted as heat, directly contributing to higher system efficiency and reducing the demands on the cooling system. This allows for a more compact heatsink and overall system design.

The following table provides a functionally grouped overview of its core electrical and thermal characteristics, based on the official datasheet. These values are essential for performing accurate loss calculations and thermal modeling during the system design phase.

| FP15R12W1T4 Key Specifications | ||

|---|---|---|

| Function | Parameter | Value |

| Inverter Stage | Collector-Emitter Voltage (Vces) | 1200V |

| Continuous Collector Current (Ic) @ Tc=80°C | 15A | |

| Collector-Emitter Saturation Voltage (VCE(sat)) @ Ic=15A | 1.50V (Typ.) | |

| Brake Chopper | Collector-Emitter Voltage (Vces) | 1200V |

| Continuous Collector Current (Ic) @ Tc=80°C | 15A | |

| Rectifier Stage | Repetitive Peak Reverse Voltage (VRRM) | 1200V |

| Forward Current (IF) @ Tc=80°C | 25A | |

| Thermal & Mechanical | Integrated NTC Thermistor | Yes |

Note: The parameters listed above are highlights. For exhaustive data, including performance curves and SOA charts, it is imperative to consult the official documentation.

Download the FP15R12W1T4 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Compact Industrial Motor Control

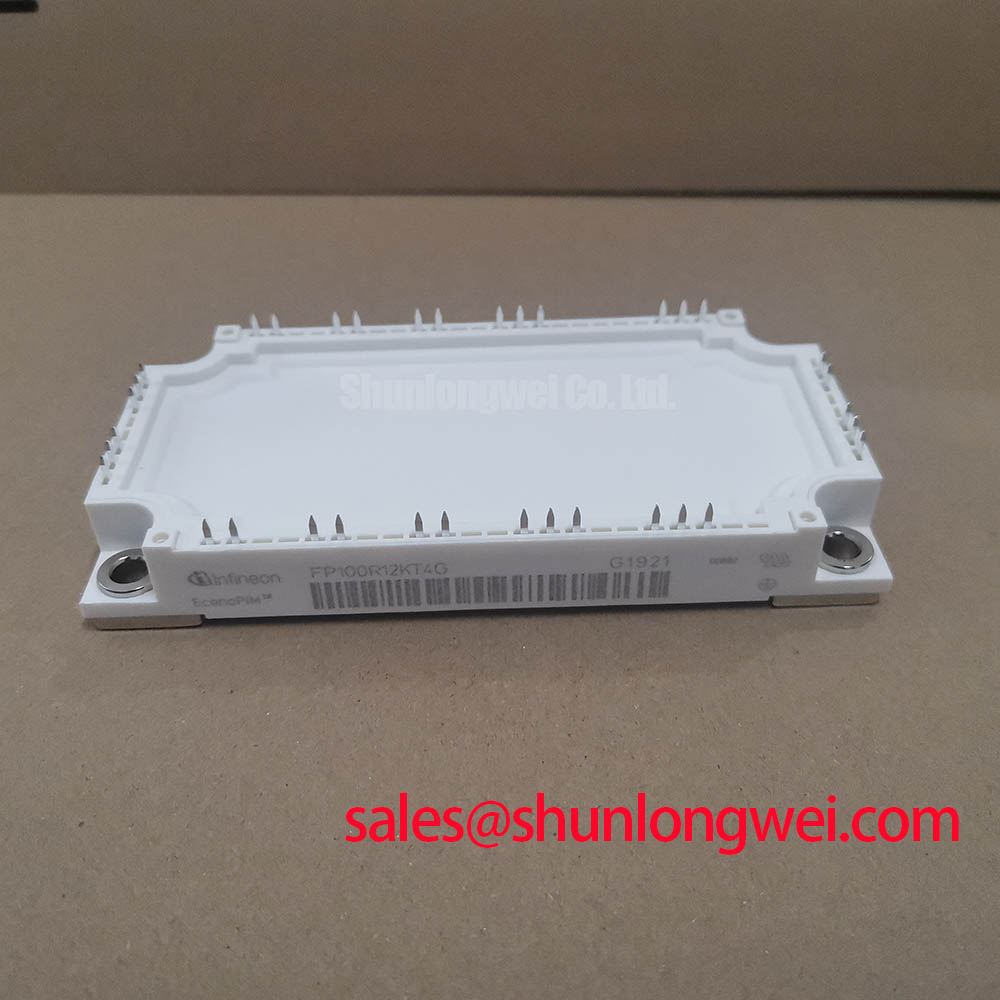

The FP15R12W1T4 is purpose-built for low-power motor control systems where footprint and efficiency are the primary engineering drivers. Its high level of integration makes it an ideal solution for compact Variable Frequency Drives (VFDs), servo drives, and the power stages of industrial machinery like packaging equipment, conveyor systems, and automated handling robotics. For systems requiring higher power output, the related FP40R12KE3 offers an increased current rating within a similar technology family.

Consider the challenge of designing a decentralized VFD that must be mounted directly onto a motor or a small control cabinet. Space is extremely limited, and thermal dissipation is a major concern. The FP15R12W1T4 directly addresses this scenario. By integrating the three-phase input rectifier, brake chopper, and output inverter into a single EasyPIM™ 1B housing, it eliminates the need for multiple discrete components. This not only shrinks the required PCB area but also simplifies the assembly process, reducing manufacturing time and cost. The module's use of TRENCHSTOP™ IGBT3 technology ensures that switching and conduction losses are kept to a minimum, easing the thermal management burden in such a tightly packed environment.

Frequently Asked Questions

Engineering Questions on the FP15R12W1T4

What is the primary benefit of the FP15R12W1T4's topology?Its key advantage is the 7-in-1 integration, combining a three-phase input rectifier, a brake chopper, and a three-phase inverter in one module. This drastically reduces the component count, simplifies the power stage layout, and minimizes the overall footprint of the final application, which is crucial for compact motor drives.

How does the integrated NTC thermistor improve system reliability?The NTC thermistor provides a direct and accurate measurement of the module's internal temperature. This allows the system's microcontroller to implement precise over-temperature protection, preventing the IGBTs from operating beyond their safe thermal limits. This real-time feedback is a critical feature for ensuring long-term operational reliability and preventing catastrophic failures in demanding industrial automation environments.

Technical Deep Dive

A Closer Look at the 7-in-1 Topology and TRENCHSTOP™ IGBT3 Technology

The architecture of the FP15R12W1T4 is a prime example of functional integration in power electronics. The module contains seven distinct power semiconductor devices configured for a complete drive application. This includes six IGBTs with six anti-parallel freewheeling diodes forming the three-phase inverter, and a seventh IGBT with its diode for the brake chopper function. Additionally, it incorporates a full three-phase diode bridge for AC-to-DC rectification. This consolidation is a significant design advantage, as it simplifies procurement, inventory management, and the physical assembly of the power unit.

Internally, the module leverages proven Infineon IGBT technology designed to balance conduction and switching losses effectively. The TRENCHSTOP™ IGBT3 design provides low VCE(sat) to minimize heat generation during the on-state, which is dominant in low-frequency motor control applications. Simultaneously, it offers optimized switching characteristics to reduce energy loss during the turn-on and turn-off transitions. The inclusion of an NTC thermistor co-packaged within the module is a critical reliability feature. The integrated NTC acts as a built-in thermometer pressed directly against the module's core. This provides the control system with a direct, real-time temperature reading, allowing for a rapid response to thermal stress—a far more effective protection mechanism than an external sensor that might lag in detecting a thermal runaway event. For a deeper understanding of how component technology impacts system design, explore this in-depth analysis of IGBT modules.

For engineering teams developing next-generation compact motor drives or upgrading existing designs for better performance and a smaller form factor, the FP15R12W1T4 presents a compelling, all-in-one solution. To discuss the specific requirements of your application or to request a quote, please contact our technical sales team for further information.