Content last revised on January 21, 2026

FP15R12YT3 IGBT Module: Efficiency Analysis for Motor Drives

Technical Evaluation of the Infineon FP15R12YT3 IGBT Module

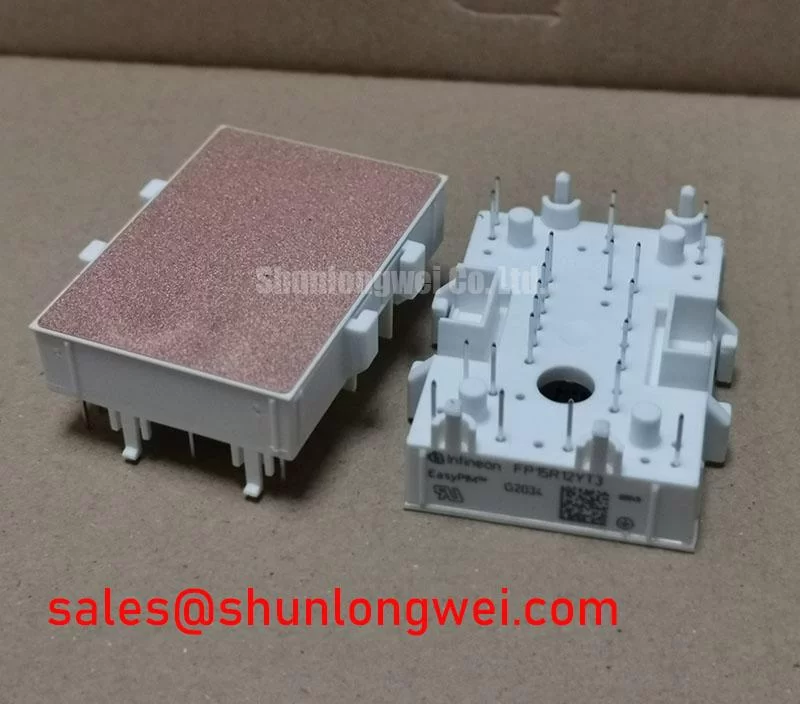

The Infineon FP15R12YT3 is a highly integrated power module designed to maximize efficiency in low-power motor drives and inverter applications. At its core, this module leverages Infineon's advanced TRENCHSTOP™ IGBT3 technology to achieve a superior balance between conduction and switching losses. It integrates a full three-phase inverter bridge with a brake chopper and a three-phase diode rectifier into a single, compact EconoPIM™ 2 housing. This level of integration directly addresses the engineering challenge of creating high-density power stages without compromising thermal performance, a key consideration for modern, space-constrained industrial electronics.

Driving Industrial Efficiency Through Advanced Semiconductor Design

In an industrial landscape increasingly governed by stringent energy efficiency standards, the performance of power conversion stages is critical. The FP15R12YT3 directly supports this trend by incorporating technologies that minimize energy waste. Its low collector-emitter saturation voltage (VCE(sat)) reduces heat generated during operation, which not only improves system efficiency but also lessens the burden on thermal management systems. For engineers developing next-generation Variable Frequency Drives (VFDs) or servo controllers, leveraging such a component can be instrumental in meeting performance targets and regulatory requirements while potentially reducing the overall system footprint and bill of materials.

Deployment Snapshot: Enhancing Compact Servo Drive Performance

Consider a typical application in automated manufacturing, such as a robotic arm powered by multiple compact servo drives. The FP15R12YT3 is an exemplary component for this scenario. Its integrated design, combining rectifier, brake, and inverter stages, simplifies the drive's power electronics layout, saving valuable PCB space. The integrated NTC thermistor provides precise, real-time temperature feedback, allowing the drive's control system to implement sophisticated thermal protection and optimize performance under varying loads. This ensures the long-term reliability of the servo drive, a crucial factor in maintaining production uptime and reducing maintenance cycles in high-throughput industrial environments.

A Closer Look at TRENCHSTOP™ and Emitter Controlled Diode Synergy

The performance of the FP15R12YT3 is rooted in its sophisticated silicon. The module employs Infineon's TRENCHSTOP™ IGBT3, a technology known for its low saturation voltage and robust short-circuit withstand capability. This is complemented by an Emitter Controlled Diode, which is co-packaged with the IGBT. This diode is optimized for soft switching behavior and low reverse recovery losses, directly contributing to lower turn-on losses (Eon) in the IGBT. This synergistic relationship between the switch and the freewheeling diode is fundamental to achieving high switching frequencies without incurring excessive thermal penalties, enabling more compact and efficient inverter designs. The integrated NTC thermistor adds a layer of intelligent control, allowing for precise thermal monitoring to safeguard the module within its Safe Operating Area (SOA).

Core Specifications for High-Efficiency Systems

Evaluating the FP15R12YT3 requires a focus on parameters that directly influence system performance and reliability. The collector-emitter saturation voltage, VCE(sat), is a pivotal metric; its low typical value of 1.90 V at a nominal current of 15 A signifies minimal power loss during the on-state. Think of this as the electrical "friction" of the switch—the lower it is, the less energy is wasted as heat. This directly impacts the required size of the heatsink and overall system efficiency. For systems where space and energy consumption are primary design constraints, this module presents a compelling technical foundation. For a comprehensive review of all parameters, please download the official datasheet.

| Parameter | Symbol | Condition | Value | Unit |

|---|---|---|---|---|

| Collector-emitter Voltage | V_CES | 1200 | V | |

| DC Collector Current | I_C nom | TC = 80°C | 15 | A |

| Collector-emitter Saturation Voltage | V_CE sat | I_C = 15 A, V_GE = 15 V, Tj=25°C | 1.90 | V |

| Total Power Dissipation | P_tot | TC = 25°C | 110 | W |

| Switching-on Energy | E_on | IC=15A, VCE=600V, VGE=±15V, RGon=39Ω, Tj=125°C | 1.25 | mJ |

| Switching-off Energy | E_off | IC=15A, VCE=600V, VGE=±15V, RGoff=39Ω, Tj=125°C | 1.30 | mJ |

Engineered for Precision: Primary Application Scenarios

The integrated and efficient nature of the Infineon FP15R12YT3 makes it a strong candidate for a range of low to medium power applications where reliability and power density are paramount. Its design is particularly well-suited for systems that benefit from a reduced component count and simplified assembly.

- Motor Control & Drives: The all-in-one configuration is ideal for compact variable frequency drives (VFDs) and servo drives used in industrial automation, robotics, and HVAC systems.

- Uninterruptible Power Supplies (UPS): Its efficiency and integrated brake chopper are valuable in online UPS systems, ensuring minimal energy loss and effective battery management.

- Switched Mode Power Supplies (SMPS): The module can serve as the core power stage in high-reliability industrial power supplies.

For motor drive applications up to approximately 4 kW prioritizing simplified thermal management and a compact footprint, the FP15R12YT3's integrated PIM configuration is an optimal design choice over discrete component solutions.

Data-Informed Component Evaluation

When selecting a power module, engineers must weigh multiple technical trade-offs. The FP15R12YT3, housed in the EconoPIM™ 2 package, offers a clear advantage in system integration. Compared to designs using separate discrete components for the rectifier, brake, and inverter, this module significantly reduces PCB complexity, assembly time, and potential points of failure. While discrete solutions may offer more granular control over component selection, the FP15R12YT3 provides a pre-validated, thermally optimized subsystem. For instance, in applications where space is at a premium, a compact module like the FP25R12KE3 offers higher current density in a similar form factor, presenting a clear upgrade path for designs requiring more power output without a major layout overhaul.

For detailed technical specifications and application notes to support your design process, we encourage you to review the official product documentation or contact our team for assistance in sourcing the FP15R12YT3 for your power conversion projects.