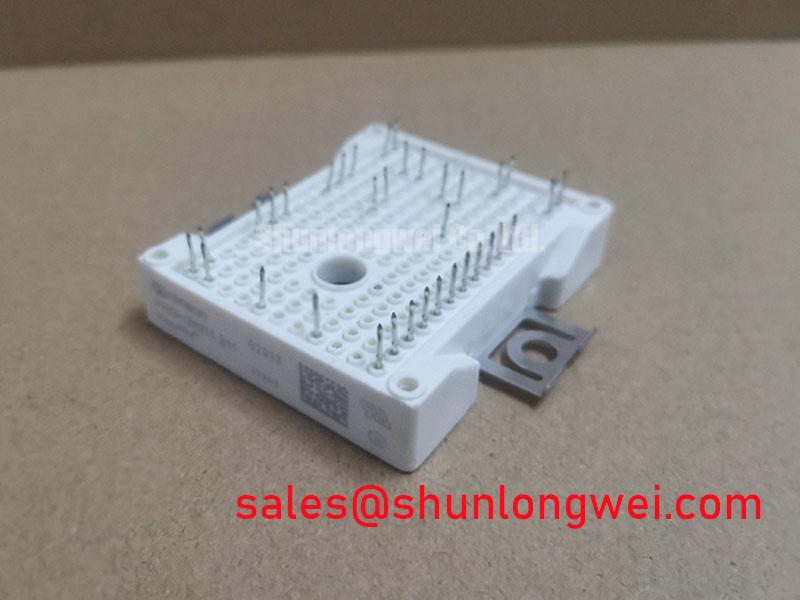

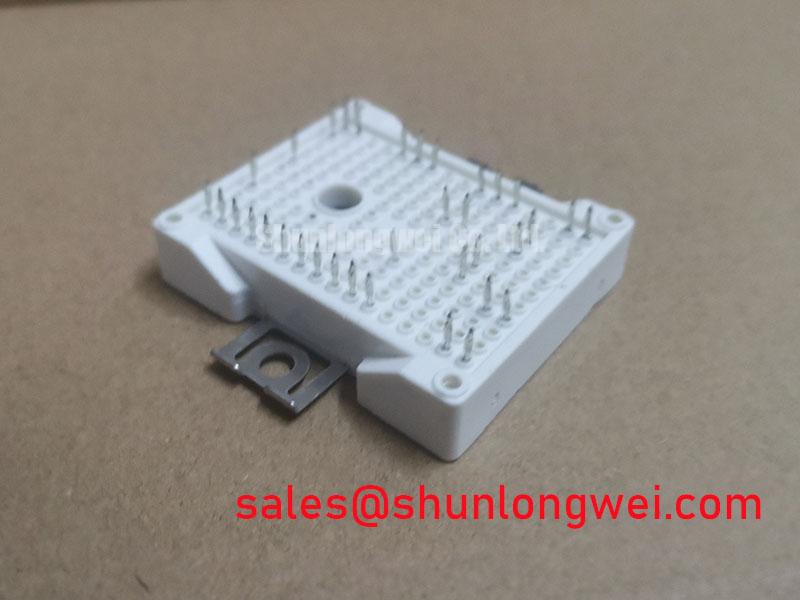

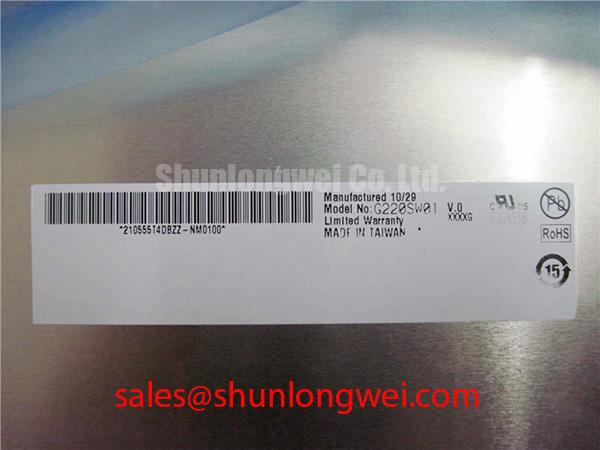

FP26R12W2T4_B11 IGBT Module: Technical Data and Application Insights

An Engineering-Focused Overview of the 1200V, 26A Six-Pack IGBT Module

Content last revised on October 9, 2025.

The Infineon FP26R12W2T4_B11 is a highly integrated power module designed for efficiency and reliability in compact inverter designs. It leverages TrenchSTOP™ IGBT4 technology to deliver a robust solution for variable speed drives. Key specifications include: 1200V collector-emitter voltage | 26A nominal current | Integrated NTC temperature sensor. This design provides significant benefits, including optimized low-power loss operation and enhanced thermal performance. The module directly addresses the engineering challenge of balancing performance and thermal management in space-constrained applications like servo drives and small industrial motors. For systems demanding higher power density under 2.5 kHz switching frequencies, the module's low VCE(sat) makes it a superior choice.

Key Parameter Overview

Decoding the Specs for Efficient Low-Frequency Drive Design

The technical specifications of the FP26R12W2T4_B11 are tailored for performance in low to medium power applications. The parameters below highlight its capabilities in managing conduction losses and ensuring thermal stability, which are critical for long-term operational reliability.

| Parameter | Value | Conditions |

| Collector-Emitter Voltage (V_CES) | 1200 V | V_GE = 0 V, T_vj = 25°C |

| DC Collector Current (I_C nom) | 26 A | T_C = 80°C |

| Collector-Emitter Saturation Voltage (V_CE sat) | 1.85 V (Typ.) | I_C = 25 A, V_GE = 15 V, T_vj = 25°C |

| Total Power Dissipation (P_tot) | 160 W | T_C = 25°C |

| Gate-Emitter Threshold Voltage (V_GE(th)) | 5.8 V | I_C = 1.00 mA, V_CE = V_GE, T_vj = 25°C |

| Thermal Resistance, Junction-to-Case (R_thJC) | 0.98 K/W (per IGBT) | - |

| Diode Forward Voltage (V_F) | 1.90 V (Typ.) | I_F = 25 A, V_GE = 0 V, T_vj = 25°C |

| Short Circuit Withstand Time (t_SC) | 10 µs | V_GE ≤ 15 V, V_CC = 800 V, T_vj ≤ 150°C |

Download the FP26R12W2T4_B11 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Compact Motor Drives and Power Conversion

The FP26R12W2T4_B11 is engineered for applications where power density and thermal efficiency are primary design constraints. Its primary value is realized in systems operating at lower switching frequencies where conduction losses are the dominant factor in overall efficiency.

A high-fidelity engineering scenario is in the development of a compact Servo Drive for an automated packaging machine. The key challenge is minimizing the drive's physical volume to fit within the machine's crowded chassis, which strictly limits heatsink size. The FP26R12W2T4_B11's low typical V_CE(sat) of 1.85V directly translates to lower heat generation during the on-state. This reduction in waste heat allows engineers to specify a smaller, more cost-effective heatsink while maintaining a safe operating junction temperature, thereby enabling a more compact and reliable final product. This focus on conduction performance makes it an ideal fit for applications such as:

- Low-power general-purpose inverters

- Servo drives for industrial automation

- Air conditioning compressor controls

- Small-scale pumping systems

For systems requiring slightly higher current handling within a similar package, the related FP35R12W2T4_B11 provides an increased current rating while maintaining the benefits of the EasyPIM™ housing.

Technical Deep Dive

Inside the EasyPIM™ Housing: Optimizing for Thermal Transfer

A critical, yet often overlooked, feature of the FP26R12W2T4_B11 is its housing and the thermal path from the silicon to the heatsink. The module's specified thermal resistance from junction to case (R_thJC) of 0.98 K/W per IGBT is a key enabler of its performance. This value is not just a number; it represents the efficiency of heat extraction. Think of it like the diameter of a pipe: a lower R_thJC value is a wider pipe, allowing more heat (thermal energy) to flow away from the sensitive IGBT junction for the same temperature difference. This efficient "pipe" is fundamental to achieving the module's rated current without exceeding the maximum junction temperature of 175°C under operating conditions. This robust thermal design is a direct contributor to the module's long-term reliability and its ability to withstand operational stresses in demanding industrial environments.

Industry Insights & Strategic Advantage

Meeting Efficiency Standards in Industrial Automation

The FP26R12W2T4_B11 is well-positioned to help designers meet evolving energy efficiency regulations for industrial machinery. As standards like IEC 61800-9-2 (Ecodesign for motor systems) become more stringent, minimizing losses in the Variable Frequency Drive (VFD) is paramount. The TRENCHSTOP™ IGBT4 technology within this module provides a proven platform for reducing both conduction and switching losses compared to previous generations. By integrating a six-pack configuration with an NTC thermistor into a single EasyPIM™ package, the module simplifies the design of compact and efficient VFDs. This integration reduces component count, assembly complexity, and potential points of failure, offering a strategic advantage for OEMs aiming to deliver reliable, compliant, and cost-effective motor control solutions.

Frequently Asked Questions (FAQ)

What is the primary benefit of the 1.85V typical V_CE(sat) in a real-world application?

A lower V_CE(sat) directly reduces the power lost as heat when the IGBT is conducting current. This means lower operating temperatures, which allows for smaller heatsinks, increases system reliability, and improves overall energy efficiency, particularly in applications with high duty cycles like motor drives.

How does the integrated NTC thermistor simplify system design?

The built-in NTC provides a direct, real-time temperature reading of the module's baseplate. This allows the drive's control system to implement precise over-temperature protection without the need for external sensors, reducing component count, wiring complexity, and assembly costs while improving the accuracy of thermal monitoring.

Is the FP26R12W2T4_B11 suitable for high switching frequency applications?

This module utilizes IGBT4 technology, which is optimized for a balance between low conduction losses (V_CE(sat)) and moderate switching losses. It is best suited for applications with switching frequencies typically below 8 kHz. For higher frequency designs, other IGBT technologies might offer a more favorable loss profile.

What does the 10µs short-circuit withstand time rating imply for system protection?

The 10µs rating defines a critical safety window. It specifies the maximum duration the IGBT can survive a direct short-circuit condition before catastrophic failure. This gives the gate drive and system protection circuitry a defined timeframe to detect the fault and safely shut down the IGBT, ensuring the robustness of the overall system.

As industrial systems demand greater efficiency within smaller footprints, component selection becomes a strategic decision. The FP26R12W2T4_B11 offers a compelling solution by providing a thermally efficient, integrated power stage that simplifies the design of reliable, low-power motor drives. Its architecture supports the development of next-generation industrial equipment that is both compact and compliant with modern energy standards, representing a forward-looking choice for system architects.