FZ600R65KF2 6500V High-Voltage IGBT Module: Engineering for Medium-Voltage Power Systems

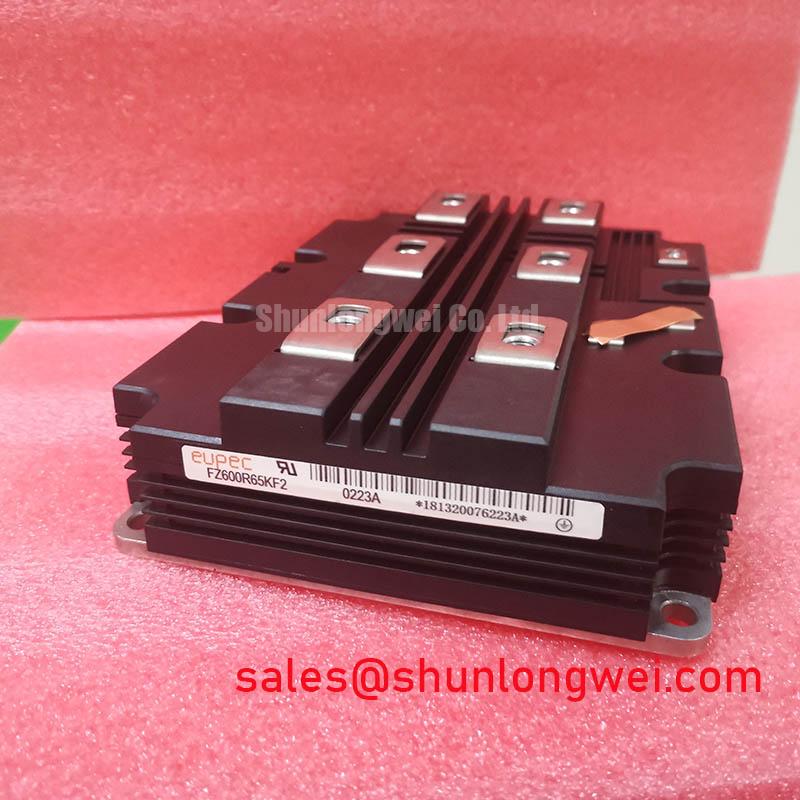

Introduction to the FZ600R65KF2 High-Power IGBT Module

The FZ600R65KF2 is a high-power IGBT module engineered to deliver exceptional reliability in demanding medium-voltage power conversion applications. With its core specifications of 6500V | 600A | VCE(sat) 4.3V (typ.), this component provides two critical engineering benefits: superior voltage blocking capability and robust current handling. This module directly addresses the challenge of designing efficient and durable inverters for systems operating on 3.3kV to 4.16kV AC lines, offering the high dielectric strength required to ensure safe and stable operation over a long service life. For medium-voltage drives prioritizing reliability and design margin, this 6500V module provides a definitive building block.

Application Scenarios & Value

System-Level Benefits in Medium-Voltage Converters and Industrial Drives

The primary value of the FZ600R65KF2 lies in its ability to operate reliably in high-voltage power electronics, most notably in Medium Voltage Converters. These systems are the backbone of heavy industrial applications such as large motor drives for mining, marine propulsion, and utility-scale energy systems. A key engineering challenge in these multi-megawatt systems is managing the high DC-link voltage, which can approach several kilovolts. The FZ600R65KF2's massive 6500V collector-emitter blocking voltage (VCES) provides the essential safety margin to withstand voltage transients and ensure stability without requiring complex series-connection of lower-voltage IGBTs, which simplifies the overall topology of a Variable Frequency Drive (VFD).

Consider a high-power VFD for a conveyor system in a mining operation. The drive must reliably control a multi-megawatt motor under harsh conditions. Using the FZ600R65KF2 allows designers to build a two-level or three-level inverter topology with fewer series components per valve. This directly translates to reduced component count, lower gate drive complexity, and improved system reliability by minimizing potential points of failure. The module's robust 600A continuous current rating ensures it can handle the demanding torque and speed requirements of such heavy-duty machinery. While this module is optimized for the multi-kilovolt range, for systems operating at lower voltages such as 1700V, a component from a different voltage class like the FZ600R17KE3 may be evaluated.

Key Parameter Overview

Decoding the Specs for High-Voltage Reliability

The performance of the FZ600R65KF2 is defined by a set of critical parameters that directly influence its behavior in high-voltage circuits. The following table highlights the specifications most relevant for design engineers focused on reliability and performance.

| Parameter | Symbol | Condition | Value | Unit |

| Collector-Emitter Voltage | VCES | Tvj = 25°C | 6500 | V |

| Continuous DC Collector Current | IC,nom | - | 600 | A |

| Repetitive Peak Collector Current | ICRM | tP = 1 ms | 1200 | A |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 600A, VGE = 15V, Tvj = 125°C | 4.90 (typ.) / 5.30 (max.) | V |

| Gate-Emitter Threshold Voltage | VGE(th) | IC = 24mA, VCE = VGE, Tvj = 25°C | 5.0 (min.) / 5.8 (typ.) / 6.5 (max.) | V |

| Thermal Resistance, Junction to Case | RthJC | per IGBT | 13.5 | K/kW |

| Operating Junction Temperature | Tvj op | - | -40 to +125 | °C |

Download the FZ600R65KF2 datasheet for detailed specifications and performance curves.

Frequently Asked Questions (FAQ)

What is the primary benefit of the FZ600R65KF2's 6500V VCES rating in system design?

The 6500V rating provides a substantial safety margin for inverters connected to 3.3kV AC lines. Think of VCES as the height of a dam; the 6500V "dam" can safely hold back the electrical "pressure" of the system, including significant voltage spikes that occur during switching events. This high blocking voltage is critical for ensuring long-term reliability and preventing catastrophic failure in high-voltage industrial applications.

How does the collector-emitter saturation voltage (VCE(sat)) of 4.9V (typ.) at 125°C influence thermal design?

VCE(sat) is a direct contributor to conduction losses. A VCE(sat) of 4.9V at the nominal current of 600A means that during the on-state, the module will dissipate approximately 2940 watts (P = V * I). Engineers must use this value in their thermal calculations, combined with the RthJC, to design an adequate heatsink and cooling system that keeps the junction temperature below the 125°C maximum, ensuring the module operates within its Safe Operating Area (SOA).

What is the significance of the repetitive peak collector current (ICRM) being double the nominal current?

The 1200A ICRM rating indicates the module's ability to handle short-duration current pulses, which are common in motor drive applications during acceleration or under sudden load changes. This robustness ensures the module can survive transient conditions without degradation, a key factor for reliability in demanding industrial environments.

Is an NTC thermistor included in this module?

The provided datasheet for the FZ600R65KF2 does not explicitly list an integrated NTC thermistor within the characteristic values section. Systems requiring direct temperature feedback for over-temperature protection would need to implement an external temperature sensing solution adjacent to the module's baseplate for accurate Thermal Management.

What kind of gate driver is recommended for this high-voltage IGBT?

A 6.5kV IGBT requires a specialized gate driver that provides high isolation voltage, sufficient gate current for fast switching, and robust protection features like Active Clamping and short-circuit detection. Drivers specifically designed for high-voltage applications are essential to ensure both the safety of control electronics and the reliable operation of the IGBT module itself.

Strategic Advantage in Critical Infrastructure

Integrating the FZ600R65KF2 into new system designs offers a strategic advantage beyond immediate performance. For engineers developing next-generation medium-voltage drives, traction converters, or grid-tied inverters, this module provides a foundation built on high-voltage ruggedness. Its capability allows for simplified, more reliable inverter architectures that can enhance the total cost of ownership by reducing component count and potential failure points. This focus on inherent robustness makes it a forward-looking choice for critical infrastructure projects where long-term operational integrity is non-negotiable.