Content last revised on October 22, 2025.

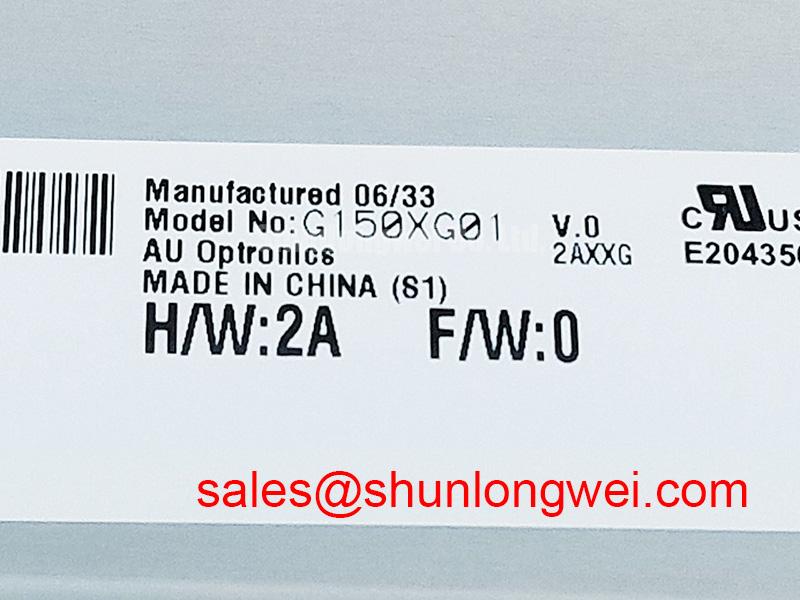

AUO G150XG02 V0: A Robust 15.0" XGA Display Engineered for Industrial Longevity

Introduction and Key Highlights

Engineered for High-Clarity Industrial HMI and Control Applications

The AUO G150XG02 V0 is a 15.0-inch a-Si TFT-LCD panel engineered for sustained performance in demanding industrial environments. It delivers a strategic combination of high brightness, proven backlight technology, and a standard interface, ensuring both visual clarity and integration simplicity. With its core specifications of 1024x768 XGA | 550 cd/m² Brightness | 60,000-Hour CCFL Backlight, this display provides exceptional readability and operational longevity. Key engineering benefits include a long-life backlight system that reduces maintenance cycles and a high-contrast optical design for clear data visualization. For systems requiring a durable, high-brightness XGA display with a proven technology stack, the G150XG02 V0 offers a reliable and efficient solution. With its high typical brightness and robust CCFL backlight, this display is best suited for industrial control panels and legacy system upgrades where long-term operational reliability is paramount.

Application Scenarios & Value

Delivering System-Level Benefits in Industrial Control and Legacy Upgrades

The G150XG02 V0 is optimized for applications where consistent, long-term performance and readability are critical engineering requirements. Its feature set directly addresses the challenges faced in industrial automation, medical equipment interfaces, and point-of-sale (POS) systems.

A primary engineering challenge in industrial HMI design is ensuring machine operators can clearly and quickly interpret data under variable factory lighting. The G150XG02 V0's high typical brightness of 550 cd/m² combined with a 500:1 contrast ratio directly solves this problem. This level of luminance ensures that status indicators, process values, and safety warnings are easily legible, minimizing the risk of operator error. What is the primary benefit of its long-life backlight? Reduced total cost of ownership by minimizing maintenance and downtime over the product's lifecycle.

Furthermore, its standard 4:3 aspect ratio and XGA resolution make it an ideal drop-in replacement for aging control panels on legacy equipment like CNC machines or process controllers. This allows for system modernization without the need for extensive mechanical or software redesign. For applications requiring a different balance of features, the related G150XTN04.0 provides an alternative solution within the 15-inch XGA category.

Key Parameter Overview

Specifications Profile with Engineering Value Interpretation

The technical specifications of the AUO G150XG02 V0 are tailored for industrial integration, emphasizing reliability and visual performance. The following table highlights key parameters and interprets their direct value in system design.

| Parameter | Specification | Engineering Value & Interpretation |

|---|---|---|

| Screen Size | 15.0 inches | Provides a substantial viewing area suitable for complex graphical user interfaces (GUIs) in industrial machinery and instrumentation. |

| Resolution | 1024(RGB)×768, XGA | Offers a standard resolution that is widely supported by industrial PCs and embedded systems, ensuring broad compatibility for new and retrofit projects. |

| Brightness | 550 cd/m² (Typ.) | Delivers high luminance for excellent readability in typical indoor industrial and commercial settings, ensuring critical data is clearly visible. |

| Backlight System | CCFL, 60,000 Hours (Typ.) | The extended lifespan of the CCFL backlight is a key reliability metric. Think of it as the operational life of a critical engine component; its 60k-hour rating ensures years of continuous service, directly reducing maintenance frequency and associated costs. |

| Viewing Angle | 70/70/70/50 (L/R/U/D) (Typ.) | Provides consistent image quality from various operator positions, crucial for control panels accessed by multiple users from different angles. |

| Signal Interface | LVDS (1 channel, 8-bit), 20 pins | Utilizes a standard, low-noise LVDS interface, simplifying electrical integration and ensuring robust data transmission between the controller and the panel. |

| Operating Temperature | 0°C to 50°C | Designed for stable operation within controlled industrial environments, suitable for factory floors and control rooms. |

| Surface Treatment | Antiglare, Hard Coating (3H) | The antiglare surface diffuses ambient light to minimize reflections, while the 3H hard coat provides essential protection against scratches in high-traffic operational areas. |

Download the G150XG02 V0 datasheet for detailed specifications and performance curves.

Technical Deep Dive

Analyzing the Impact of Backlight Longevity and Surface Treatment

Two features of the AUO G150XG02 V0 merit closer examination from an engineering standpoint: its 60,000-hour CCFL backlight lifespan and its robust surface treatment.

The 60,000-hour rating on the CCFL backlight is not just a number; it is a direct indicator of the display's long-term reliability and low total cost of ownership. For a system intended to operate 24/7, this translates to nearly seven years of continuous operation before the backlight reaches half its initial brightness. This longevity is critical in applications like industrial process monitoring or medical equipment, where system downtime for component replacement is highly disruptive and costly. This extended life is analogous to specifying a bearing in a motor for continuous duty; it's a fundamental design choice for building a reliable system from the ground up.

Secondly, the combination of an antiglare (AG) surface and a 3H hard coating provides a dual benefit of optical performance and physical durability. The AG treatment effectively mitigates specular reflections from overhead lighting, a common issue on factory floors that can obscure critical information. The 3H hard coat provides a significant level of scratch resistance, protecting the panel's surface from accidental contact in busy work environments. This robust surface ensures the display maintains its optical clarity and usability throughout its service life.

Frequently Asked Questions (FAQ)

What is the significance of the 550 cd/m² brightness for industrial HMI design?

A brightness of 550 nits is significantly higher than typical consumer-grade displays, making it well-suited for the ambient lighting conditions found in factories and control rooms. It ensures that the display remains clear and legible, which is crucial for operator efficiency and safety.

How does the 60,000-hour CCFL backlight lifetime translate to real-world operational benefits?

This extended lifespan directly reduces the total cost of ownership. It minimizes the need for maintenance interventions to replace the backlight, ensuring higher system uptime and reliability, particularly for equipment that runs continuously.

Is the LVDS interface on the G150XG02 V0 suitable for electrically noisy environments?

Yes, the Low-Voltage Differential Signaling (LVDS Interface) is inherently robust against common-mode noise. Its differential nature makes it a reliable choice for industrial applications where electromagnetic interference (EMI) from motors and drives can be a concern.

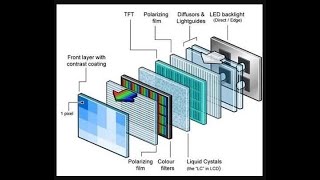

What does the TN, Normally White display mode mean for my application?

TN (Twisted Nematic) is a mature and cost-effective LCD technology known for fast response times. "Normally White" means that if a pixel fails, it will appear white. This is often preferred in industrial or medical applications where a failed-dark pixel could obscure a critical warning or data point.

Can the G150XG02 V0 be used as a replacement for older 15-inch XGA panels?

With its standard XGA resolution, 4:3 aspect ratio, and common LVDS interface, the G150XG02 V0 is an excellent candidate for upgrading or replacing panels in existing systems. However, designers must always verify the mechanical dimensions, connector types, and pin assignments to ensure full compatibility.

From an Engineer's Perspective

A Strategic Choice for Reliability-Focused Systems

From a system design perspective, the AUO G150XG02 V0 represents a conservative but highly effective engineering choice. It prioritizes proven technologies—a high-longevity CCFL backlight and a standard AUO a-Si TFT panel—to deliver predictable, reliable performance. For projects where the primary objective is to build a robust HMI or control interface with a long service life and minimal maintenance requirements, this display is a foundational component. Its specifications are not about pushing the boundaries of display technology but about providing a stable, dependable platform that allows engineers to focus on their core application logic, confident in the visual interface's durability and clarity.