## LM150X08-A4NA: Technical Breakdown of a 15.0-inch XGA Industrial Display

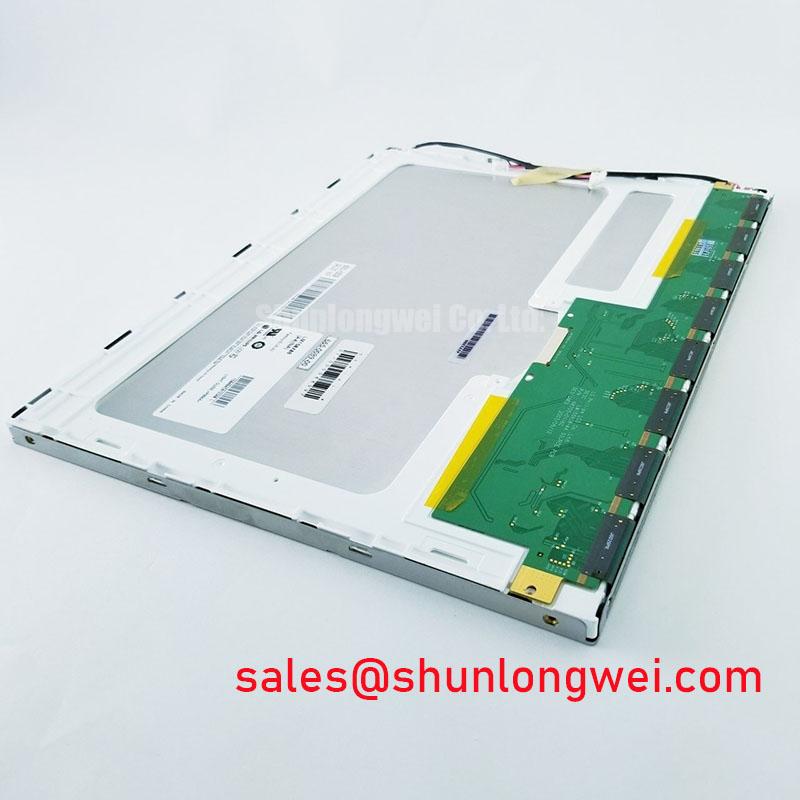

The LM150X08-A4NA is a 15.0-inch a-Si TFT-LCD module delivering proven performance for legacy and long-lifecycle industrial systems. It provides a stable, high-clarity visual interface with its 1024x768 XGA resolution, 250 cd/m² brightness, and a 400:1 contrast ratio. Key benefits include excellent front-of-screen uniformity and robust mechanical stability. This display addresses the critical need for a reliable 4:3 aspect ratio panel in applications where frequent redesigns are impractical and operational consistency is paramount. For industrial HMI or control systems requiring a standard XGA interface with consistent visual output, the LM150X08-A4NA offers a field-proven solution.

### Application Scenarios & Value

System Integration & Design Simplification for Established Platforms

The LM150X08-A4NA is engineered for seamless integration into industrial machinery, process control terminals, and specialized instrumentation where reliability and a consistent form factor are primary design drivers. Its standard 15.0-inch footprint and XGA resolution make it an ideal candidate for retrofitting or maintaining existing equipment lines, minimizing the need for costly mechanical or software redesigns.

A key engineering challenge in maintaining long-running industrial systems is component sourcing that preserves system validation. The LM150X08-A4NA directly addresses this with its conventional 1-channel, 8-bit LVDS interface and CCFL backlight system. This allows engineers to specify a replacement or ongoing production component without overhauling the system's core video processing or power architecture. The display's 3.3V logic voltage further simplifies integration with established embedded systems. For systems requiring a different visual profile, the G150XNE-L01 offers an alternative with LED backlight technology and higher brightness.

### Key Parameter Overview

Decoding the Specs for Mechanical Robustness & Environmental Resilience

The technical specifications of the LM150X08-A4NA are tailored for durability and consistent performance in demanding operational environments. The parameters below highlight its mechanical stability and optical characteristics, which are crucial for industrial applications.

| Specification | Value | Engineering Value |

|---|---|---|

| Panel Size | 15.0 inch | Provides a large, clear viewing area suitable for complex data visualization in HMIs and control panels. |

| Resolution | 1024(RGB)×768, XGA | Delivers crisp, legible text and graphics, essential for reducing operator error in monitoring applications. |

| Brightness | 250 cd/m² (Typ.) | Ensures adequate visibility in typical indoor industrial lighting conditions. |

| Contrast Ratio | 400:1 (Typ.) | Offers clear differentiation between colors and shades, improving the readability of detailed schematics or status indicators. |

| Viewing Angle (L/R/U/D) | 65/65/45/55 (Typ.) (CR≥10) | Provides a functional viewing cone for fixed-mount applications where the operator is typically positioned directly in front of the screen. |

| Surface Treatment | Antiglare (Haze 13%), Hard coating (3H) | Reduces distracting reflections from overhead lighting and provides essential scratch resistance against incidental contact in a factory setting. |

| Outline Dimensions | 326.5(W) × 253.5(H) × 11.7(D) mm | Defines a robust mechanical frame, ensuring compatibility with standard industrial enclosures and mounting systems. |

| Backlight System | CCFL (2 pcs), 40,000 hours (Min.) | The dual-lamp system with a long rated lifetime ensures sustained brightness and reduces maintenance cycles over the product's operational lifespan. |

Download the LM150X08-A4NA datasheet for detailed specifications and performance curves.

### Frequently Asked Questions (FAQ)

What is the primary benefit of the Antiglare (Haze 13%) surface treatment?

Its primary benefit is enhanced readability in industrial environments. The antiglare surface diffuses ambient light, preventing harsh reflections from overhead sources from obscuring the screen content, which is a critical factor for operator efficiency and safety.

How does the 3H hard coating contribute to the display's durability?

The 3H hard coating provides significant protection against scratches and minor abrasions. This is comparable to the hardness of some plastics and protects the polarizer from damage during installation or in operational environments where tools or gloved hands may come into contact with the screen.

Is the CCFL backlight system field-replaceable?

While the CCFL tubes have a long rated life of 40,000 hours minimum, their replacement is a specialized process that typically requires disassembly of the display module in a clean environment. It is generally not considered a user-serviceable part in the field.

What does the 6 o'clock viewing direction signify for system design?

The 6 o'clock viewing direction indicates that the optimal image quality, particularly for grayscale inversion, is achieved when viewing the display from slightly below the center. Designers should mount the display so that the primary operator's line of sight is at or slightly above the horizontal centerline of the screen.

What is the typical application for a display with a 75Hz vertical frequency?

A 75Hz refresh rate provides smoother motion for cursors or simple animations compared to a standard 60Hz display. This makes it well-suited for legacy industrial control systems or point-of-sale terminals where responsiveness and reduced visual flicker are important for the user interface.

Technical Deep Dive

An Analysis of the LVDS Interface and its Role in System Reliability

The LM150X08-A4NA utilizes a single-channel, 8-bit LVDS (Low-Voltage Differential Signaling) interface. This is a critical design choice that directly impacts electrical noise immunity and system integration. Unlike older parallel interfaces like TTL, LVDS uses differential pairs to transmit data. This means two wires carry opposite-polarity versions of the same signal. The receiver interprets the difference between these signals, a technique that effectively cancels out common-mode noise picked up along the cable length.

In an industrial setting, rife with electromagnetic interference (EMI) from motors, VFDs, and high-power switching, this noise immunity is not a trivial feature. It ensures signal integrity over longer cable runs between the display and the host controller, preventing data corruption that could manifest as flickering, incorrect colors, or a complete loss of image. This inherent robustness simplifies the electrical design, often reducing the need for extensive shielding and filtering that would be required with single-ended interfaces, thereby supporting a more straightforward and reliable system architecture.

An Engineer's Perspective

From an engineering standpoint, the LM150X08-A4NA represents a commitment to stability over cutting-edge specifications. Its value lies not in market-leading brightness or resolution, but in its proven architecture. The combination of a standard XGA resolution, a common LVDS interface, and a well-understood CCFL backlight creates a component that is predictable and dependable. For projects involving the maintenance of critical infrastructure or industrial equipment with a certified 10+ year lifespan, this predictability is invaluable. It allows for confident system planning, knowing that the display's performance characteristics and mechanical fit will remain consistent, ensuring long-term operational continuity without forcing a complete system requalification.