P760A06 Thyristor Module | 600V 754A SCR for Industrial Power Control

Content last revised on October 10, 2025.

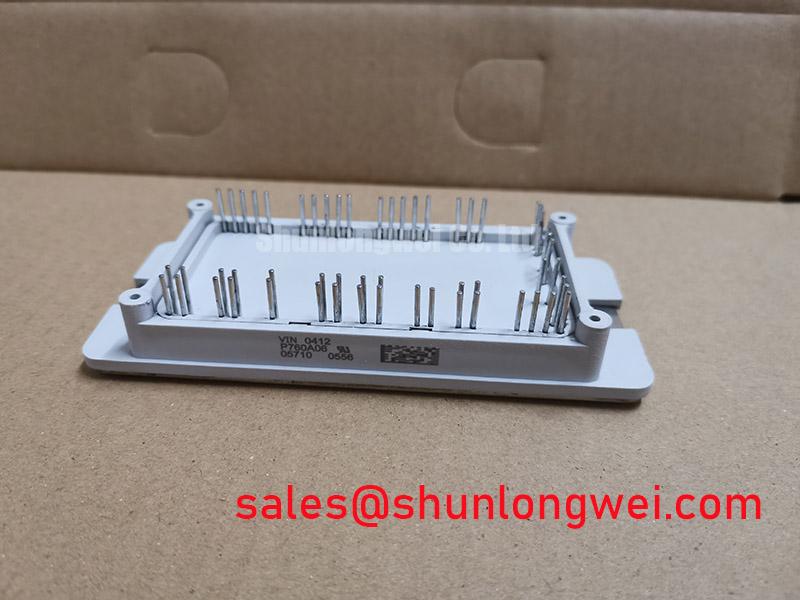

The P760A06 is a high-current 600V phase control thyristor engineered for superior reliability and thermal management in demanding power conversion systems. At its core, this component delivers a robust set of specifications—600V blocking voltage | 754A average state current | 8500A peak surge current (ITSM)—translating into tangible engineering benefits like enhanced thermal cycling lifespan and high fault current survivability. It directly addresses the critical need for robust, high-current switching in industrial equipment that experiences significant repetitive stress. For high-power AC controllers and soft starters requiring maximum operational reliability, the P760A06's pressure-contact design offers a distinct performance advantage.

Application Scenarios & Value

System-Level Benefits in Heavy Industrial Power Control

The P760A06 is designed for high-power phase control applications where reliability under electrical and thermal stress is a primary design consideration. Its capabilities are best demonstrated in systems like industrial motor soft starters, high-current rectifiers, and AC power controllers for heating or welding.

Consider the engineering challenge of a motor soft starter for a large industrial conveyor system. The initial motor startup creates a massive inrush current, a repetitive event that can degrade conventional power modules over time. The P760A06's exceptional non-repetitive surge current rating of 8500A provides a substantial safety margin to withstand these peaks without degradation. This high ITSM value is a critical parameter that allows engineers to design a more robust and reliable system, minimizing downtime and maintenance costs. What is the surge current rating? The P760A06 can handle a non-repetitive surge of 8500 Amps, ensuring survivability during fault or inrush conditions.

This component's design philosophy prioritizes longevity in harsh environments. While the P760A06 is optimized for 230-400V AC line applications, for systems operating on higher voltage grids, the related SKKD162/16 provides a 1600V blocking capability.

Key Parameter Overview

Functional Breakdown for System Design

The specifications of the P760A06 are indicative of a device built for high-stress, continuous operation. The parameters below are grouped by function to facilitate efficient evaluation for your power system design.

| Blocking Characteristics (Tj = 125°C) | |

|---|---|

| VDRM/VRRM, Repetitive Peak Voltage | 600 V |

| IDRM/IRRM, Peak Leakage Current @ VDRM/VRRM | 50 mA |

| On-State Characteristics (Tj = 125°C) | |

| IT(AV), Average On-State Current @ Tcase=60°C | 754 A |

| IT(RMS), RMS On-State Current | 1184 A |

| VTM, Max On-State Voltage @ IT=2000A | 1.55 V |

| ITSM, Max Surge Current (10ms, 50Hz) | 8500 A |

| I2t, I2t-value for fusing (10ms) | 361 kA2s |

| Thermal & Mechanical Characteristics | |

| Rth(j-c), Thermal Resistance, Junction to Case (Double-Sided Cooling) | 0.029 °C/W |

| Tvj op, Operating Junction Temperature Range | -40 to 125 °C |

| FM, Mounting Force | 8 to 12 kN |

Download the P760A06 datasheet for detailed specifications and performance curves.

Technical Deep Dive

The Reliability Advantage of Pressure-Contact Technology

A key differentiator for the P760A06 is its capsule, or "puk," package. This design necessitates a mounting method known as pressure-contact, which offers fundamental advantages over conventional soldered power modules. In a pressure-contact system, the silicon die is held under a precise clamping force, establishing electrical and thermal connections without solder layers. What is the primary benefit of its capsule package? Enhanced reliability through elimination of solder fatigue and enabling efficient double-sided cooling.

This design directly mitigates a common failure mode in high-power electronics: solder fatigue. In applications with frequent temperature changes—such as motor drives or furnaces—the expansion and contraction of different materials can cause solder joints in standard modules to crack over time, leading to thermal runaway and device failure. The P760A06's solder-free interface makes it inherently more resilient to thermal cycling, contributing to a significantly longer operational lifespan. For a deeper understanding of how packaging impacts component life, see this guide on how packaging dictates thermal performance.

Frequently Asked Questions (FAQ)

What makes the 8500A ITSM rating significant for system design?

This high surge current rating provides a critical safety margin, allowing the device to survive large, non-repetitive inrush currents or short-circuit fault conditions without immediate failure. For engineers, this translates to higher system robustness, potentially simplifying overcurrent protection circuitry and improving the overall reliability of the end equipment, especially in motor drives and capacitor charging circuits.

How does the capsule package of the P760A06 contribute to long-term reliability compared to a standard module?

The capsule package utilizes a pressure-contact mounting system that eliminates solder layers between the semiconductor element and the external contacts. This design is inherently immune to solder fatigue, a primary wear-out mechanism in power modules subjected to frequent temperature fluctuations. This results in superior longevity and reliability in applications with demanding thermal cycles.

What is the practical benefit of the low VTM (on-state voltage)?

A lower on-state voltage (VTM) at a given current means less power is dissipated as heat during conduction. For the P760A06, this efficiency translates directly into lower operational temperatures or the ability to use a smaller, more cost-effective heatsink. This improves the system's overall power density and can reduce cooling system costs, a key consideration in compact and high-power designs. This is directly related to the component's Thermal Resistance and management strategy.

Engineering Support and Component Sourcing

For detailed application notes, thermal modeling data, and support in integrating the P760A06 into your power system design, please contact our technical sales team. We can provide the necessary documentation and guidance to help you leverage the full performance and reliability of this high-power phase control thyristor.