Content last revised on February 2, 2026

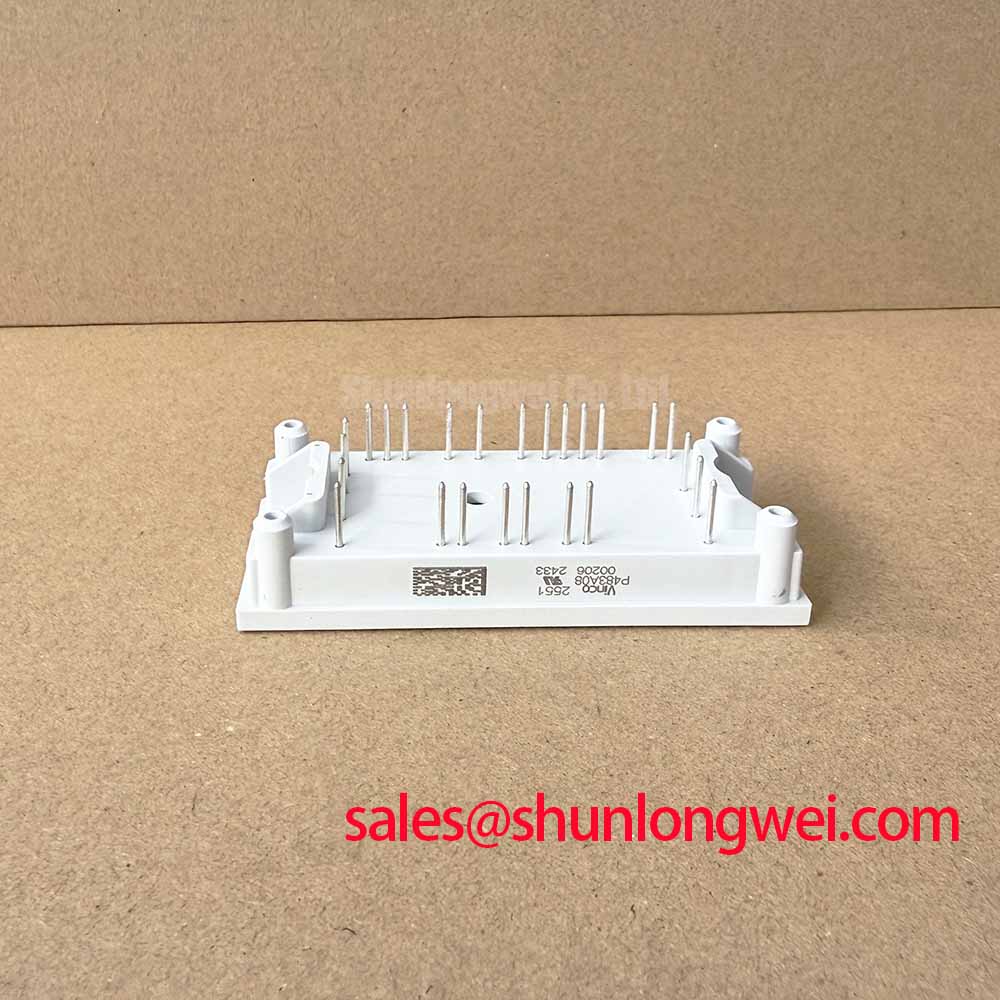

VincoTech P843A08 flowPIM 1 IGBT Module: High-Density Thermal Solution for Compact 3-Phase Inverters

The VincoTech P843A08 is a high-performance Power Integrated Module (PIM) designed within the flowPIM 1 housing, integrating a three-phase input rectifier, a brake chopper, and a three-phase output inverter into a single, space-optimized footprint. Operating at 600V with a collector current of 30A, this module is engineered for low-power industrial motor control where thermal efficiency and board-space conservation are critical design constraints. By consolidating the entire power stage and an integrated NTC thermistor, the P843A08 allows engineers to simplify Variable Frequency Drive (VFD) layouts while maintaining high reliability in 400V AC systems.

For industrial designers prioritizing thermal margins, the VincoTech P843A08 offers an optimized Rth path that facilitates superior heat dissipation in HVAC and pump applications. What is the primary benefit of its integrated NTC thermistor? It provides real-time internal temperature monitoring to prevent catastrophic thermal runaway. For 400V systems prioritizing thermal margin and component density, the 600V 30A P843A08 module is the optimal choice for high-efficiency inverter designs.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the P843A08 reflect a balance between switching speed and ruggedness. The flowPIM 1 package is renowned for its low inductive path and high integration level. The following table highlights the critical operating parameters sourced from the official technical documentation.

| Parameter Group | Technical Specification | Value/Attribute |

|---|---|---|

| Voltage Rating | Collector-Emitter Voltage (Vces) | 600V |

| Current Handling | Collector Current (Ic) @ Tc=80°C | 30A |

| Configuration | Module Topology | PIM (Rectifier + Brake + Inverter) |

| Packaging | Housing Type | flow 1 (flowPIM) |

| Thermal Monitoring | Temperature Sensor | Integrated NTC Thermistor |

| Switching Characteristic | Technology Generation | Low Loss IGBT |

Download the P843A08 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Achieving System-Level Benefits in High-Frequency Power Conversion

Engineers often face the "thermal congestion" challenge when designing compact motor controllers for HVAC Systems. The VincoTech P843A08 addresses this by utilizing a flow 1 housing that minimizes the thermal barrier between the silicon die and the heatsink. In a typical micro-case study, a Variable Frequency Drive (VFD) controlling a 5.5kW industrial pump requires rapid PWM switching. The P843A08, with its 600V headroom, manages the voltage spikes induced during inductive load switching without requiring oversized snubber circuits.

In applications such as Industrial Automation and Servo Drives, the integration of the brake chopper (BRCK) within the module allows for controlled deceleration of high-inertia loads. This avoids external component clutter and reduces the overall TCO (Total Cost of Ownership) by simplifying assembly. While this module is ideal for 30A peak requirements, for systems requiring significantly higher current handling, the related 6MBI450U-120 offers a Vces of 1200V with a 450A rating. For further insights into how these modules drive modern efficiency, explore our resource on IGBT Modules as the backbone of high-efficiency power systems.

Technical & Design Deep Dive

A Closer Look at the Low-Inductance Layout for Long-Term Reliability

The internal architecture of the P843A08 is optimized to reduce stray inductance. In high-speed switching environments, stray inductance can lead to significant voltage overshoots, potentially exceeding the 600V limit during turn-off. The flowPIM 1 package uses a symmetric layout that balances current distribution across the inverter bridges. Think of thermal resistance (Rth) in this module as a wide, clear exit path; just as a crowd exits a stadium faster through multiple wide gates, the heat generated in the P843A08 silicon flows more freely to the baseplate due to the thin-ceramic DCB (Direct Copper Bond) substrate.

Furthermore, the Integrated NTC is strategically placed near the center of the IGBT chips. This proximity is like having a dedicated scout inside an engine room, reporting real-time status directly to the gate driver's control logic. This allows for proactive derating if the ambient temperature in the Industrial LCD control cabinet rises beyond safety thresholds. Designers must adhere to strict Gate Drive protocols to ensure the P843A08 remains within its Safe Operating Area (SOA) during short-circuit events. For comparative analysis of different gate drive strategies, see our guide on robust IGBT gate drive design.

FAQ

How does the flow 1 housing of the P843A08 benefit compact inverter designs?

The flow 1 housing provides an extremely high power density by integrating the rectifier, brake, and inverter into a single module. This significantly reduces PCB trace lengths, which lowers parasitic inductance and allows for a smaller overall footprint in HVAC and Servo Drive applications.

What is the engineering significance of the 600V rating in 400V AC systems?

A 600V rating provides a necessary safety margin for 400V AC rectified DC buses (typically 540V-560V DC). It allows the P843A08 to handle the transient overvoltages common in industrial environments without the immediate risk of dielectric breakdown, provided that the RBSOA (Reverse Bias Safe Operating Area) is respected.

Can the P843A08 be used for high-frequency switching above 20kHz?

The P843A08 utilizes low-loss IGBT technology optimized for standard industrial frequencies. While it can operate at higher frequencies, switching losses increase linearly. Engineers should consult the thermal resistance (Rth) data to ensure that the total power dissipation does not exceed the junction temperature limits at elevated frequencies.

For procurement professionals and lead engineers evaluating the VincoTech P843A08 for upcoming production cycles, detailed technical support is available to assist in integrating this IGBT Module into your specific power topology. To confirm technical compatibility or discuss high-volume requirements for your next Variable Frequency Drive project, contact our technical sales team for data-backed insights.