Content last revised on January 25, 2026

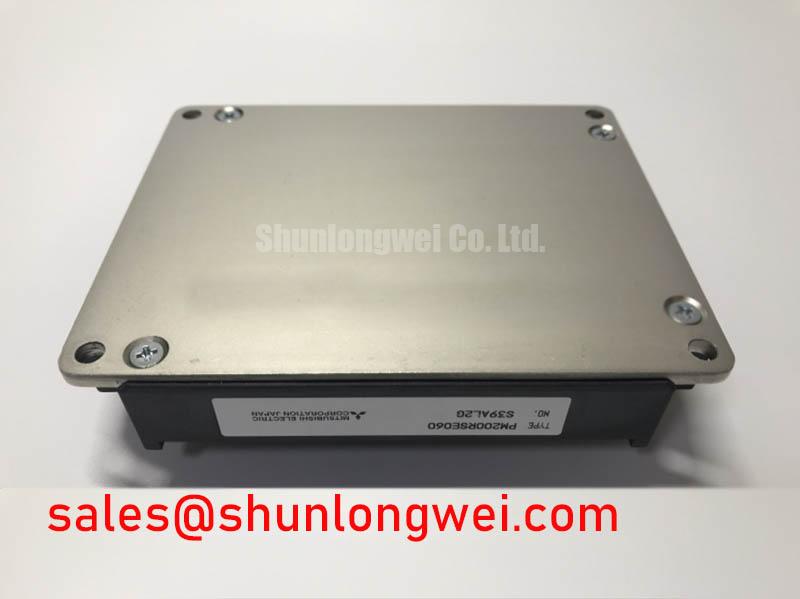

PM200RSE060 Mitsubishi IGBT Module: An In-Depth Engineering Review

Product Overview: PM200RSE060 Intelligent Power Module (IPM)

Decoding the Specs for High-Efficiency Power Conversion

The Mitsubishi PM200RSE060 is a 600V, 200A Intelligent Power Module (IPM) engineered for robust performance in high-frequency power conversion systems. With a collector-emitter saturation voltage (VCE(sat)) of 2.2V and integrated protection circuits, this module delivers a potent combination of low conduction losses and high operational reliability. It directly addresses the engineering need for compact, efficient, and fault-tolerant inverter designs. The module's integrated nature simplifies the gate drive circuit and provides critical protection, reducing both design complexity and time-to-market. For motor control applications demanding high reliability under variable load conditions, the PM200RSE060's blend of performance and protection offers a decisive advantage.

Key Parameter Overview

Analyzing Performance Metrics for System-Level Benefits

The specifications of the PM200RSE060 are tailored for demanding inverter and motor drive applications. Each parameter is critical for assessing its performance within a power electronics system. The low VCE(sat) is particularly significant as it directly correlates to lower heat generation during operation, a key factor in thermal management.

| Parameter | Value | Engineering Implication |

|---|---|---|

| Collector-Emitter Voltage (VCES) | 600V | Provides a sufficient voltage margin for systems operating on 200V-240V AC lines, ensuring reliability against voltage transients. |

| Collector Current (IC) | 200A | Supports high-power applications such as industrial motor drives and servo systems up to approximately 75 kW. |

| Collector-Emitter Saturation Voltage (VCE(sat)) | 2.2V (Typ) | A low saturation voltage minimizes conduction losses, directly enhancing system efficiency and reducing the thermal load on the heatsink. Think of it as electrical friction; lower VCE(sat) means less energy is wasted as heat when the switch is on. |

| Power Dissipation (PC) | 892W | Defines the maximum amount of heat the module can dissipate, a critical limit for thermal design and ensuring long-term operational stability. |

| Junction Temperature (Tj) | -20°C to +150°C | A wide operating temperature range ensures robust performance in harsh industrial environments and provides headroom for thermal design. |

| Isolation Voltage (Viso) | 2500V (AC, 1 min.) | Guarantees high electrical isolation between the power circuit and the control logic/mounting base, which is crucial for safety and system integrity. |

Download the PM200RSE060 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Delivering Reliability and Efficiency in Industrial Automation

Best Fit: The PM200RSE060 is optimally suited for 3-phase industrial motor drives where reducing design complexity and ensuring fault tolerance are primary engineering goals. In a typical Variable Frequency Drive (VFD) application, the challenge often lies in implementing robust protection against over-current, short-circuit, and over-temperature events without adding significant external circuitry. The PM200RSE060 directly solves this by integrating drive, control, and protection logic into a single package. This integration not only shrinks the PCB footprint but also inherently improves reliability by minimizing interconnects and ensuring tightly coordinated protection. The result is a more compact, efficient, and resilient power stage for applications like CNC machinery, commercial HVAC systems, and industrial robotics. For systems requiring a different current rating but similar integrated functionality, the PM150CVA120-2 offers a 150A alternative.

Frequently Asked Questions (FAQ)

What is the primary benefit of using an Intelligent Power Module (IPM) like the PM200RSE060 over discrete IGBTs?

The primary benefit is system simplification and enhanced reliability. The PM200RSE060 integrates the gate driver and a suite of protection features (short-circuit, over-temperature, and under-voltage lockout), which reduces component count, simplifies PCB layout, and provides optimized, high-speed fault protection that is difficult to achieve with a discrete solution.

How does the integrated under-voltage (UV) protection function improve system robustness?

The UV protection circuit ensures that the IGBTs are not driven with insufficient gate voltage. Operating with low gate voltage can cause the IGBTs to enter a high-dissipation linear mode, leading to rapid overheating and failure. The PM200RSE060 automatically shuts down the gate drive if the control supply voltage drops, preventing this catastrophic failure mode.

What does the "RSE" in the part number signify?

In the context of Mitsubishi IPMs, the "RSE" series typically denotes a specific generation or feature set. It generally points to a module designed for high performance with built-in control and protection functions, aimed at simplifying inverter design for applications like motor control.

Can the PM200RSE060 be used for applications other than motor control?

Yes, while optimized for motor drives, its characteristics make it suitable for other high-frequency power conversion applications, such as large-scale UPS (Uninterruptible Power Supply) systems, welding power supplies, and industrial inverters where efficiency and robust protection are required.

What are the key considerations for the heatsink design when using this module?

The central consideration is ensuring the junction temperature (Tj) remains below its 150°C maximum under worst-case operating conditions. The heatsink's thermal resistance must be low enough to dissipate the heat generated, which can be calculated based on the module's power dissipation (PC) and its internal thermal resistance. Proper mounting with appropriate thermal interface material is crucial to achieve the specified thermal performance.

Technical Deep Dive

A Closer Look at Integrated Protection for Enhanced System Reliability

A critical, yet often underestimated, feature of the PM200RSE060 is its integrated short-circuit (SC) protection. In a power system, a short-circuit event can deliver catastrophic levels of current in microseconds. Designing a discrete circuit that can detect this fault and safely shut down the IGBTs within the required timeframe (typically under 10µs) is a significant engineering challenge. The PM200RSE060 solves this internally. It uses an on-chip sensor to monitor the VCE(sat) voltage. During a short-circuit, the IGBT desaturates, causing a rapid rise in VCE. The internal logic detects this rise and initiates a "soft" shutdown of the IGBT. This controlled turn-off is vital; an abrupt shutdown would create a massive voltage spike (dV/dt) due to stray inductance, potentially destroying the device. This integrated, optimized protection mechanism is a key differentiator that elevates system-level reliability far beyond what is typically achievable with separate driver and protection ICs.

An Engineer's Perspective on Strategic Implementation

From a design engineering standpoint, the PM200RSE060 represents a strategic trade-off that prioritizes reliability and design velocity. While discrete IGBTs may offer more granular control over switching characteristics, the integrated approach of this Intelligent Power Module de-risks the most challenging aspects of power stage design: gate drive optimization and fault protection. The value lies not just in the component itself, but in the engineering hours saved and the increased robustness of the final product. For development teams tasked with creating compact and dependable industrial drives under tight schedules, adopting a proven, integrated solution like the PM200RSE060 is often the most efficient path to a successful and market-ready design.