Content last revised on January 4, 2026

PM20CEF060-5 Datasheet, Specs & Applications | 20A 600V CIB IPM

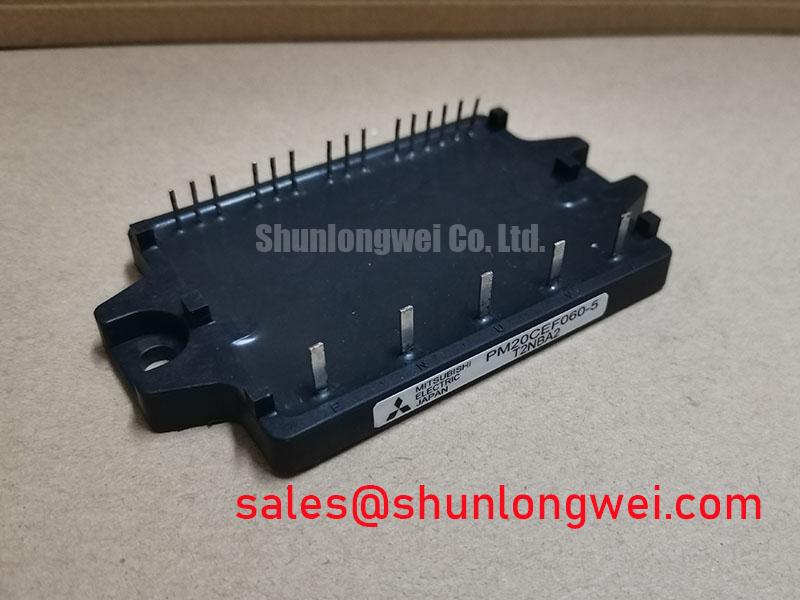

An Engineering-Focused Overview of the Mitsubishi PM20CEF060-5 Intelligent Power Module

The Mitsubishi PM20CEF060-5 is a highly integrated CIB (Converter-Inverter-Brake) Intelligent Power Module (IPM) that simplifies the design and enhances the reliability of low-power motor drives. This module combines critical power stages with advanced control and protection, featuring core specifications of 600V | 20A | VCE(sat) 1.75V (typ). Its key engineering benefits include significantly accelerated time-to-market and superior system-level reliability. By integrating the converter, inverter, brake chopper, gate drivers, and protection circuits into a single, compact E-Series package, the PM20CEF060-5 directly addresses the engineering challenge of creating space-constrained and robust motor control systems. For variable frequency drives up to 1.5 kW requiring robust protection and a compact footprint, the PM20CEF060-5 offers an optimal integrated solution.

Key Parameter Overview

Decoding the Electrical Characteristics for Integrated Motor Drive Design

The performance of the PM20CEF060-5 is defined by its electrical characteristics, which are optimized for efficiency and reliability in motor control applications. The module incorporates Mitsubishi's 5th generation CSTBT™ (Carrier Stored Trench-Gate Bipolar Transistor) technology to achieve low conduction losses. Key parameters such as a collector-emitter voltage (Vces) of 600V and a collector current (Ic) of 20A make it suitable for 200-240V AC line applications. The low saturation voltage (VCE(sat)) is critical for minimizing power dissipation and reducing thermal management requirements.

| Parameter | Symbol | Conditions | Value | Unit |

|---|---|---|---|---|

| Inverter Section | ||||

| Collector-Emitter Voltage | VCES | - | 600 | V |

| Collector Current | IC | TC = 25°C | 20 | A |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 20A, VCC = 15V | 1.75 (Typ) / 2.30 (Max) | V |

| Converter Section (Diode) | ||||

| Repetitive Peak Reverse Voltage | VRRM | - | 600 | V |

| Forward Current | IF(AV) | - | 20 | A |

| Brake Section | ||||

| Collector-Emitter Voltage | VCES | - | 600 | V |

| Collector Current | IC | TC = 25°C | 20 | A |

| Control Section | ||||

| Control Supply Voltage | VCC | - | 15 (Typ) | V |

| Short Circuit Protection | SC | VCC=15V, Tj=125°C | Yes (Trip Level >31A) | - |

Application Scenarios & Value

System-Level Benefits in Compact Motion Control Systems

The primary value of the PM20CEF060-5 lies in its ability to streamline the design of compact and efficient AC motor drives. What is the primary benefit of its integrated design? Accelerated development and enhanced system reliability. This makes it an excellent choice for a wide range of industrial and commercial applications.

Consider the engineering challenge of designing a control system for a small automated conveyor or a packaging machine. Key requirements include high reliability, a small physical footprint to fit within constrained control cabinets, and rapid development to meet market demands. The PM20CEF060-5 directly addresses these needs. Its CIB topology integrates the entire power conversion and motor drive stage, acting as the complete "powertrain" for the motor. This drastically reduces the number of external components, shrinks the required PCB area, and simplifies the thermal design. Furthermore, the built-in, pre-certified protection features for short-circuit, over-temperature, and under-voltage eliminate the complex and time-consuming task of designing and validating discrete protection circuits, reducing development risk and cost. For engineers working on Servo Drive and other motion control systems, this level of integration is a decisive advantage. While the PM20CEF060-5 is ideal for applications up to ~1.5 kW, systems requiring higher power handling could utilize the related PM30CSJ060, which offers a 30A current rating.

Frequently Asked Questions (FAQ)

Engineering Questions on Implementation and Reliability

How does the integrated V_OT output on the PM20CEF060-5 enhance thermal management?

The V_OT pin provides a continuous analog voltage that is directly proportional to the temperature of the L-side IGBT chips. This allows the system's microcontroller to implement sophisticated, real-time thermal monitoring. Instead of a simple trip signal, the controller can use this data to proactively throttle power, adjust fan speed, or trigger predictive maintenance alerts, thereby maximizing performance while preventing thermal overload and improving long-term reliability.

What are the main advantages of using a CIB (Converter-Inverter-Brake) IPM like the PM20CEF060-5?

A CIB module provides a complete, single-package solution for three-phase AC motor control. The converter section rectifies the incoming AC line voltage, the inverter section drives the motor with a variable frequency output, and the brake chopper dissipates regenerative energy from the motor during deceleration. Integrating these three functions simplifies procurement, reduces assembly complexity, minimizes PCB space, and lowers overall system cost compared to using discrete components for each stage.

Does the short-circuit protection in the PM20CEF060-5 require external components to function?

No, the short-circuit (SC) protection is fully integrated. The internal control ICs monitor the collector-emitter voltage of the IGBTs. If a short-circuit event causes this voltage to rise above a predefined threshold, the control IC initiates a soft shutdown of the IGBTs and sends a fault signal to the external controller via the Fo pin. This self-contained protection mechanism enhances the ruggedness of the IPM (Intelligent Power Module) without needing external sensing resistors or complex logic.

Technical Deep Dive

A Closer Look at the Integrated Protection and Diagnostic Functions

The "Intelligent" aspect of the PM20CEF060-5 resides in its integrated control and protection circuits, which provide a critical layer of safety and simplify system design. The module reports failures through a single open-collector fault output pin (Fo), allowing a microcontroller to easily detect an issue and take appropriate action. The key built-in protections include Short-Circuit (SC), Under-Voltage (UV), and Over-Temperature (OT).

The analog temperature output (V_OT) is a particularly powerful feature for creating robust systems. It acts much like a modern car's engine temperature gauge providing real-time data to the engine control unit (ECU). Instead of a simple "too hot" warning light (a binary fault signal), it delivers a continuous stream of data. This allows the system's "brain"—the microcontroller—to make intelligent decisions, such as gradually reducing motor torque as temperatures approach a limit, rather than an abrupt shutdown. This enables graceful performance degradation under heavy load and provides invaluable data for system diagnostics and preventative maintenance, a key tenet in modern IPM-based power design.

Strategic Engineering Advantage

Opting for an integrated solution like the PM20CEF060-5 from a reputable manufacturer such as Mitsubishi is a strategic decision for engineering teams. It shifts development focus from the component-level complexities of gate drive design and protection circuits to system-level innovation and software development. By leveraging a pre-validated, highly integrated power stage, teams can reduce design cycles, mitigate project risks, and launch more reliable and compact products into competitive markets for applications like industrial pumps, fans, and general-purpose inverters.