Content last revised on January 30, 2026

PM200DSA120 IGBT Module: Engineering Analysis for High-Reliability Power Systems

A Definitive Component for Thermally Demanding Power Conversion

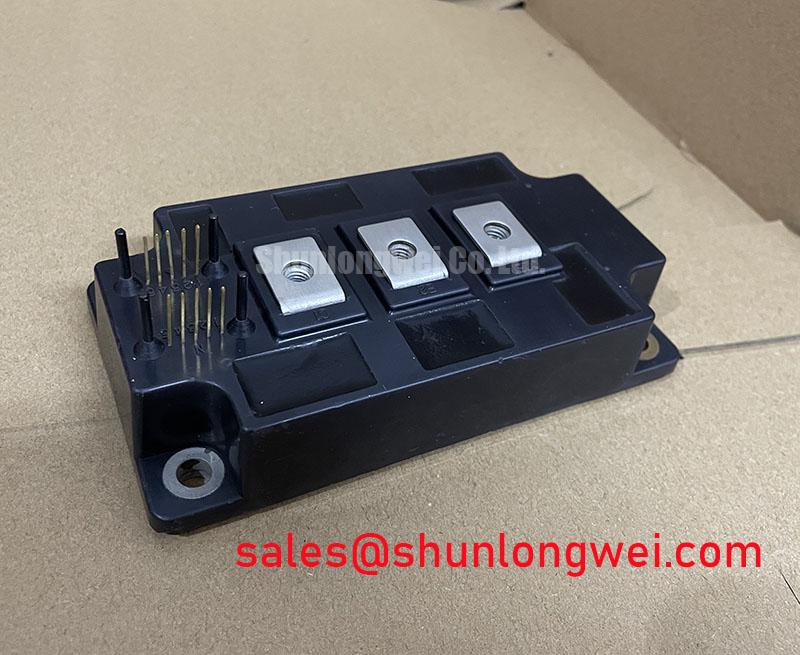

The Mitsubishi PM200DSA120 is an N-series IGBT module engineered to deliver robust performance and high reliability in demanding power conversion applications. This module provides a foundation for efficient and durable system design, focusing on superior thermal management and electrical stability. With key specifications of 1200V | 200A | VCE(sat) 2.70V (Max), it offers significant engineering advantages, including enhanced thermal dissipation and simplified inverter topology. For engineers designing medium-power industrial drives, the central challenge is managing heat under continuous load; this module directly addresses that concern through its optimized internal structure and low thermal resistance, ensuring operational integrity. What is the primary benefit of its low thermal resistance? It allows for more efficient heat dissipation, leading to higher system reliability.

Application Scenarios & Value

System-Level Benefits in Industrial Drives and Power Conversion

For power systems up to approximately 100 kW requiring robust thermal performance, the PM200DSA120's low Rth(j-c) makes it a definitive choice. The module is primarily engineered for three-phase inverter applications where reliability and efficiency are critical operational parameters. Its specifications are well-suited for systems such as industrial Variable Frequency Drives (VFDs), servo drives for factory automation, and general-purpose inverters.

Consider the engineering challenge of a VFD controlling a 75 kW induction motor in a manufacturing facility. Such systems experience continuous thermal cycling and high current demands. The PM200DSA120's Collector Power Dissipation (Pc) rating of 1040W per arm provides the necessary headroom to manage these loads without approaching thermal limits. This robust thermal performance, detailed further in resources covering IGBT thermal characteristics, translates directly to longer system lifetime and reduced maintenance requirements. The integrated half-bridge (2-in-1) configuration simplifies the power stage layout, reducing parasitic inductance and assembly complexity compared to using discrete components. What topology does the PM200DSA120 integrate? It features a half-bridge (2-in-1) configuration.

While the PM200DSA120 is optimized for 1200V applications, for systems operating at lower bus voltages, the related PM200DSA060 offers a 600V alternative with similar current handling capabilities.

Key Parameter Overview

Highlighted Specifications for Performance Evaluation

The following parameters are critical for assessing the PM200DSA120's fit within a power electronics design. The values are presented to highlight the module's core capabilities in voltage blocking, current handling, and thermal efficiency.

| Parameter | Symbol | Conditions | Value |

|---|---|---|---|

| Collector-Emitter Voltage | VCES | - | 1200 V |

| Collector Current (DC) | IC | Tc = 25°C | 200 A |

| Collector-Emitter Saturation Voltage | VCE(sat) | Ic = 200A, Tj = 125°C | 2.70 V (Max) |

| Thermal Resistance (Junction to Case, IGBT) | Rth(j-c) | Per Arm | 0.15 °C/W (Max) |

| Thermal Resistance (Junction to Case, Diode) | Rth(j-c) | Per Arm | 0.25 °C/W (Max) |

| Maximum Junction Temperature | Tj | - | 150 °C |

| Isolation Voltage | Viso | AC, 1 minute | 2500 Vrms |

Download the PM200DSA120 datasheet for detailed specifications and performance curves.

Frequently Asked Questions (FAQ)

How does the 0.15 °C/W junction-to-case thermal resistance of the PM200DSA120 influence heatsink design?

A lower thermal resistance value like 0.15 °C/W signifies more efficient heat transfer from the IGBT chip to the module's baseplate. This efficiency allows engineers to either use a smaller, more cost-effective heatsink for a given power dissipation or to operate the module at higher power levels while maintaining a safe junction temperature, thereby improving overall system power density.

What is the significance of the dual-arm (2-in-1) configuration in system design?

The 2-in-1 or half-bridge configuration integrates two IGBTs and two free-wheeling diodes into a single package. This topology is the fundamental building block for one leg of a three-phase inverter. Using three PM200DSA120 modules creates a complete inverter power stage, simplifying the busbar layout, reducing stray inductance, and minimizing assembly time compared to designs using six individual IGBTs.

Is a negative gate voltage required for turning off the PM200DSA120?

The datasheet specifies gate-emitter voltage characteristics with a recommended turn-off voltage (VGE(off)) between 0V and -15V. While the module can be turned off with 0V, applying a negative gate voltage (e.g., -5V to -15V) provides a greater noise margin, reducing the risk of parasitic turn-on caused by high dv/dt events, which is a crucial consideration for reliable operation in noisy industrial environments.

What does the VCE(sat) of 2.70V (Max) at 125°C imply for system efficiency?

The Collector-Emitter Saturation Voltage, VCE(sat), is the voltage drop across the IGBT when it is fully on. This voltage, multiplied by the collector current, determines the conduction losses. A lower VCE(sat) means lower power loss as heat. The 2.70V maximum value at a high junction temperature of 125°C provides a worst-case figure for thermal calculations, ensuring the design remains stable and efficient even under heavy operational stress.

Technical Deep Dive

Analyzing Thermal Resistance for Long-Term Reliability

A critical, yet often underestimated, parameter in IGBT module selection is the thermal resistance, Rth(j-c). For the PM200DSA120, the IGBT's maximum Rth(j-c) of 0.15 °C/W is a key indicator of its robust design. Think of thermal resistance as the narrowness of a pipeline for heat. A low Rth(j-c) value is like a very wide pipe, allowing a large volume of heat to flow away from the delicate silicon chip to the system's heatsink with minimal obstruction.

This efficiency is fundamental to achieving long-term operational reliability. High junction temperatures accelerate material degradation within the module, particularly at the solder interfaces and aluminum bond wires. By effectively evacuating heat, the PM200DSA120 minimizes the peak temperature the chip experiences during each switching cycle. This reduction in thermal stress directly enhances the module's Power Cycling Capability, extending its operational life in applications with frequent start/stop cycles, such as servo drives or material handling systems. A comprehensive understanding of IGBT technology, such as Mitsubishi's CSTBT™, is essential for leveraging these advanced thermal properties in modern power electronics.

The PM200DSA120's design ensures that thermal management is not an afterthought but a core performance attribute. This focus enables the development of more compact, reliable, and efficient power conversion systems that can withstand the rigors of continuous industrial operation. For a broader overview of these components, explore this in-depth analysis of IGBT modules.

A Strategic Component for Modern Industrial Automation

The PM200DSA120 IGBT module represents a strategic choice for engineers focused on building power systems with longevity and operational stability. Its balanced electrical characteristics, combined with a superior thermal design, provide the necessary foundation for high-performance inverters and motor drives. By integrating this module, engineering teams can achieve designs that not only meet performance specifications but also align with long-term objectives for system reliability and reduced total cost of ownership in demanding industrial environments.