Content last revised on February 3, 2026

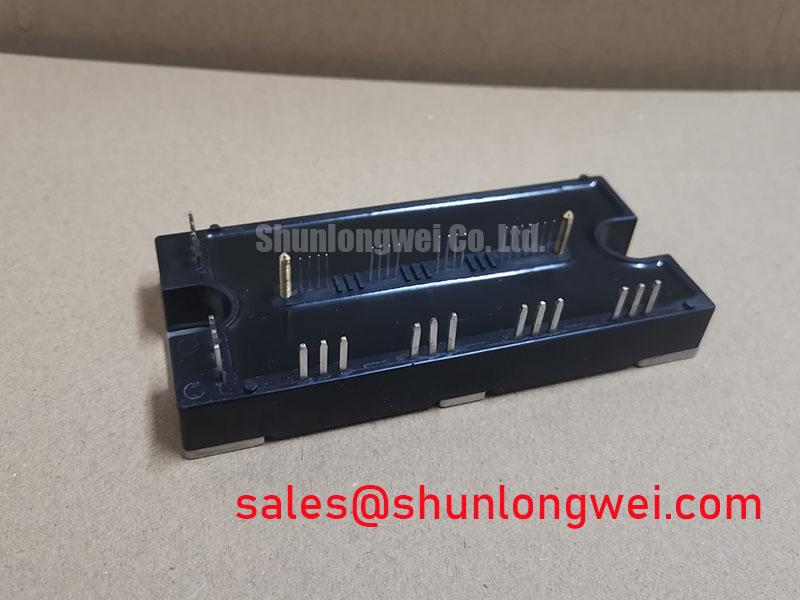

PM75CL1B060: 600V / 75A CIB Intelligent Power Module

Product Overview for the PM75CL1B060 CIB IPM

An Integrated Power Stage for Reliable, High-Density Motor Control

The Mitsubishi PM75CL1B060 is a highly integrated CIB (Converter-Inverter-Brake) Intelligent Power Module (IPM) designed to streamline and fortify low-power motor control systems. It provides a robust, single-package solution featuring key specifications of 600V | 75A, encapsulating a three-phase converter, a three-phase inverter, and a brake chopper circuit. Key engineering benefits include significantly simplified circuit design and enhanced operational reliability through built-in protection. This IPM directly addresses the challenge of achieving compact and dependable power stages in industrial drives by integrating the essential power and control elements. For industrial motor drives requiring high reliability within a compact footprint, the PM75CL1B060's integrated protection and CIB topology offer a decisive design advantage.

Application Scenarios & Value

Achieving System-Level Reliability in Compact Industrial Drives

The PM75CL1B060 is engineered for low-power three-phase motor control applications where reliability, power density, and a simplified design cycle are critical project requirements. Its all-in-one CIB topology makes it an exceptional fit for compact Variable Frequency Drive (VFD) systems, small AC servo drives, and general-purpose inverters up to approximately 3.7 kW.

Consider the design of a motor drive for a packaging conveyor system, a key component in automated logistics. A primary engineering challenge is ensuring operational uptime by protecting the system against common electrical faults like overloads and short circuits, while also managing thermal performance in a confined enclosure. The PM75CL1B060 directly solves this by integrating comprehensive protection circuits for short-circuit (SC), over-temperature (OT), and control supply under-voltage (UV). The built-in thermistor provides real-time temperature feedback, allowing the system controller to proactively manage load conditions or enhance cooling, a critical feature for preventing catastrophic failures. This level of integration eliminates the need for numerous external protection components and complex gate drive circuits, shrinking the PCB footprint and simplifying the overall design of the Motion Control system. The inclusion of a dedicated Brake Chopper further simplifies the management of regenerative energy during motor deceleration, a common requirement in such dynamic applications. For systems that demand higher current handling for larger motors, the related PM100CSD120 offers a 100A capability in a similar integrated package.

Key Parameter Overview

Defining Performance for Efficiency and Robustness

The technical specifications of the PM75CL1B060 are optimized for a balance of efficiency, thermal performance, and electrical ruggedness. The table below highlights critical parameters derived from the official datasheet. Each value is crucial for accurate system simulation, thermal design, and performance validation.

| Parameter | Symbol | Conditions | Value |

|---|---|---|---|

| Collector-Emitter Voltage | VCES | - | 600 V |

| Collector Current (DC) | IC | TC = 100°C, Per Inverter Arm | 75 A |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 75A, VCC = 15V, Tj = 25°C | 1.80 V (Typ.) / 2.30 V (Max.) |

| Short Circuit Withstand Time | tsc | VCC = 15V, VCES < 450V, Tj = 125°C | > 10 µs |

| Isolation Voltage | Viso | AC, 1 minute | 2500 Vrms |

Download the PM75CL1B060 datasheet for detailed specifications and performance curves.

Technical Deep Dive

A Closer Look at Integrated Protection and Thermal Feedback

The engineering value of the PM75CL1B060 extends beyond its power ratings to its sophisticated internal architecture. What is the primary benefit of its integrated protection? It provides a hardware-level safety net that operates faster and more reliably than software-based monitoring alone. The module incorporates dedicated circuits for short-circuit, under-voltage, and over-temperature protection. When a fault is detected—such as a phase-to-phase short at the motor terminals—the internal logic sends a fault signal (Fo) and intelligently shuts down the gate drive to the IGBTs, preventing catastrophic failure of the power stage.

Critically, the module features an integrated thermistor within the control IC (LVIC), providing an analog voltage output proportional to the chip's temperature. This is fundamentally different from modules that only offer a case-mounted NTC thermistor. This on-chip feedback gives a more accurate and immediate representation of the junction temperature of the control and drive circuitry. Think of this feature as a high-precision digital thermometer placed directly on the system's brain, rather than just on the outer casing. This allows for a more aggressive yet safe thermal design, as the controller can react to actual silicon temperature, maximizing performance without compromising the long-term reliability defined by the device's SOA (Safe Operating Area).

Frequently Asked Questions (FAQ)

What is the function of the integrated brake circuit in the PM75CL1B060?

The integrated brake chopper circuit is designed to manage regenerative energy. During rapid motor deceleration, the motor acts as a generator, sending current back to the DC bus and increasing its voltage. The brake circuit allows for the connection of an external braking resistor to dissipate this excess energy, preventing DC bus over-voltage faults and ensuring stable system operation.

How does the on-chip temperature feedback improve system design?

The integrated thermistor provides a real-time analog voltage signal directly proportional to the control IC's temperature. This enables more precise thermal management than a case-mounted thermistor. Engineers can set more accurate alarm and shutdown thresholds in the system controller, allowing the drive to operate closer to its maximum performance limits without risking thermal damage, thereby improving overall system power density and reliability.

What are the key advantages of using a CIB (Converter-Inverter-Brake) IPM over a discrete component solution?

A CIB IPM like the PM75CL1B060 drastically reduces system complexity. It combines the AC-DC rectifier, DC-AC inverter, brake chopper, and optimized gate drivers into a single, tested component. This reduces the number of components, minimizes PCB layout complexity and size, shortens assembly time, and improves reliability by minimizing parasitic inductances and ensuring component compatibility.

What supply voltage is required for the internal control logic?

The module requires a 15V DC supply for the control circuitry, including the internal gate drivers and protection logic. The datasheet specifies tight tolerances for this supply, as the under-voltage (UV) protection circuit will disable the module if the voltage drops below a safe operating threshold, typically around 12.5V-13.5V.

From a strategic perspective, investing in an integrated solution like the PM75CL1B060 is a decision to prioritize system reliability and accelerate time-to-market. By delegating critical protection and drive functions to a pre-validated module, engineering teams can focus their resources on higher-level application software and system features, confident in the robustness of the underlying power stage. This approach mitigates design risks associated with discrete power electronics and ultimately leads to a more competitive and dependable end product.