Content last revised on January 15, 2026

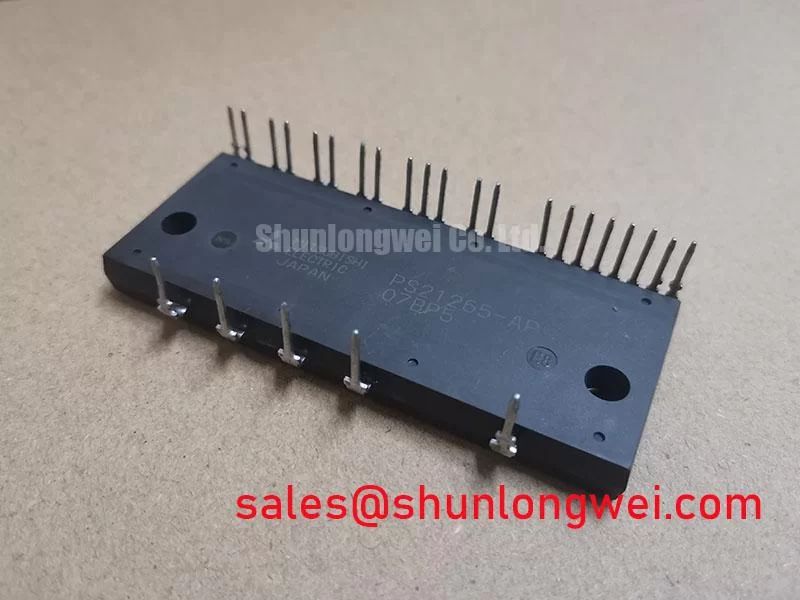

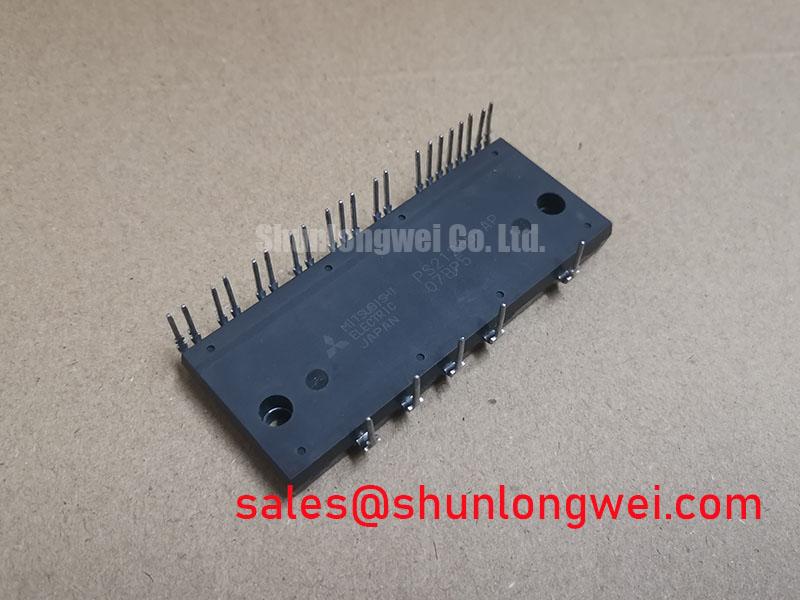

Powerex PS21265-AP | Integrated 600V, 20A DIPIPM™ for Compact Motor Drives

The Powerex PS21265-AP is an advanced DIPIPM™ (Dual-In-Line Package Intelligent Power Module) engineered to simplify and enhance the reliability of low-power three-phase inverter designs. By integrating a complete power stage with intelligent control and protection, this module provides a robust, single-package solution that dramatically accelerates development cycles for applications up to approximately 2.2kW.

Product Highlights: The Engineering Advantage

For engineers tasked with designing compact, efficient, and reliable motor control systems, the PS21265-AP offers a distinct set of advantages:

- Maximum Integration: Combines six 600V/20A IGBTs, freewheeling diodes, high- and low-side gate drivers (HVICs and LVICs), and a comprehensive protection suite in a single compact package.

- Inherent Reliability: Features built-in protection for short-circuit (SC), over-temperature (OT), and control supply under-voltage (UV), preventing common failure modes.

- Simplified Design & Assembly: Eliminates the need for complex gate drive circuitry, opto-isolators, and external protection logic, significantly reducing PCB footprint and component count.

- Optimized Performance: The internal layout is factory-optimized to minimize stray inductance and ensure compatibility between the IGBTs and their drivers, leading to improved EMI performance and switching characteristics.

A Deep Dive into the Integrated Architecture

The true value of the Powerex PS21265-AP lies in its intelligent integration. The module incorporates high-voltage ICs (HVICs) that provide level-shifting for the high-side IGBTs, allowing direct control from a 3.3V or 5V logic-level MCU. This architecture bypasses the need for costly and space-consuming pulse transformers or optocouplers, directly addressing a key pain point in compact inverter design. Furthermore, the inclusion of a full suite of protections is not merely a feature; it's a foundational element of its design philosophy. By actively monitoring for destructive events, this IPM can safeguard both itself and the motor, a critical consideration for improving the long-term reliability of an end product. Understanding these protections is key to preventing catastrophic failures; for a broader perspective, explore our guide on preventing common IGBT failure modes.

Application Scenarios & Value Proposition

The PS21265-AP is engineered to excel in applications where space, efficiency, and reliability are paramount.

- Low-Power Industrial Drives: For small variable frequency drives (VFDs), conveyors, and pump controls, this IPM enables a highly compact and cost-effective inverter stage, reducing manufacturing complexity.

- Appliance Motor Control: In high-performance home appliances like inverter air conditioners and washing machines, its low switching noise and high reliability contribute to longer product life and quieter operation.

- Robotics and Servo Drives: The module's integrated nature and fast-acting protections are ideal for powering precision in robotic servo drives, where dependable and repeatable performance is non-negotiable.

Key Technical Specifications

This table outlines the critical parameters that define the performance envelope of the PS21265-AP. For a comprehensive list of characteristics, refer to the official datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 600 V |

| Collector Current (IC) | 20 A |

| Isolation Voltage (VISO) | 1500 Vrms (1 minute) |

| IGBT Saturation Voltage (VCE(sat)) | Typ. 1.4V / Max. 2.0V (at IC = 20A, Tj = 25°C) |

| Control Supply Voltage (VCC) | 13.5V to 16.5V |

| Built-in Protections | Short-Circuit (SC), Under-Voltage Lockout (UV), Over-Temperature (OT) |

For complete electrical and thermal data, download the official PS21265-AP datasheet.

Engineer's FAQ

Why choose an IPM like the PS21265-AP over a discrete IGBT solution?

While discrete IGBTs offer design flexibility, an Intelligent Power Module (IPM) like the PS21265-AP provides superior value in terms of time-to-market, reliability, and total system cost. The pre-certified integration of power devices and drivers eliminates guesswork in layout and component matching. This reduces R&D time, minimizes PCB area, lowers assembly costs, and provides guaranteed performance and protection, which is difficult and time-consuming to achieve with a discrete design.

What is the most critical external circuit to implement with this DIPIPM?

The bootstrap circuit for the high-side gate drive supply is the most critical external element. It consists of a resistor, a fast-recovery diode, and a capacitor for each of the three high-side drivers. The correct selection of these components, particularly the bootstrap capacitor value, is essential for ensuring the high-side IGBTs receive a stable gate voltage during operation. An incorrectly designed bootstrap circuit can lead to insufficient gate drive, increased switching losses, and potential device failure. For an in-depth guide, refer to official application notes from Mitsubishi on DIPIPM™ bootstrap design. Proper implementation is one of the most practical tips for ensuring robust gate drive design and preventing system failure.