SK45GH0-63 SEMITOP® 3 IGBT Module: Engineering Product Analysis

Content last revised on October 23, 2025.

Introduction and Key Specifications

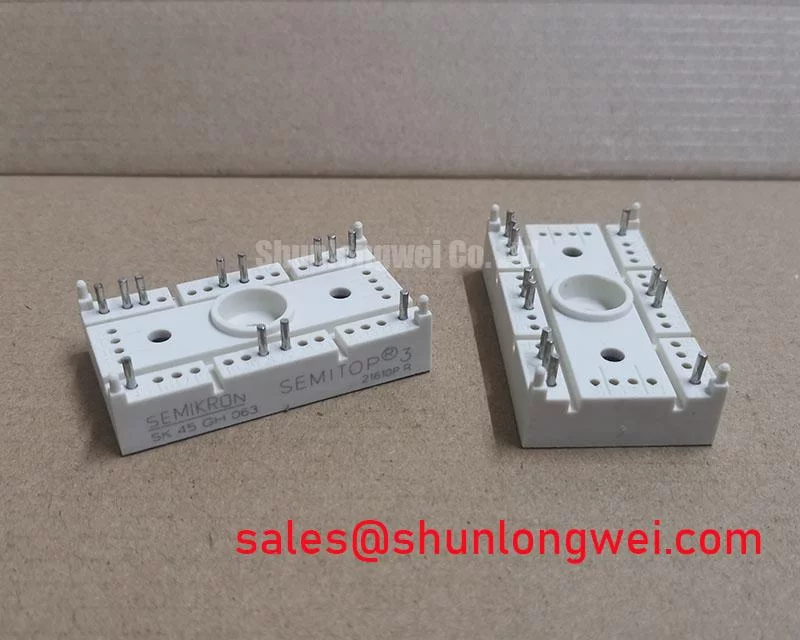

Streamlining Low-Power Drives with an Integrated H-Bridge

The SK45GH063 is a 600V, 45A IGBT module engineered for compact and thermally efficient power conversion systems. Integrating a full H-bridge into a single SEMITOP® 3 package, this module provides a robust solution for motor drives and switched-mode power supplies. Key specifications include: 600V | 45A | VCE(sat) (typ) 2.1V. Its primary benefits are simplified assembly and excellent thermal transfer. This design directly addresses the need for reducing mechanical complexity in space-constrained applications. For low-to-mid-power motor control applications requiring a balance of performance and assembly efficiency, the SK45GH063's integrated H-bridge architecture is a highly effective choice.

Application Scenarios & Value

System-Level Benefits in Motion Control and Power Conversion

The SK45GH063 is engineered for applications where power density and streamlined manufacturing are critical. Its primary role is in low-power Variable Frequency Drives (VFDs), small industrial servo motors, and DC/AC inverters. In these systems, a key engineering challenge is managing thermal dissipation while minimizing the overall footprint. The module's Direct Bonded Copper (DBC) substrate provides superior thermal conductivity to the heatsink, directly addressing this issue. This allows for smaller heatsink designs and more compact final products. What is the main advantage of its single-module H-bridge design? It significantly reduces component count and assembly time compared to using four discrete IGBTs. While this 600V module is well-suited for 230/400V systems, for applications demanding higher current, designers might consider the related BSM75GD120DN2 which offers a 1200V rating.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the SK45GH063 are tailored for reliable performance in demanding switching applications. The parameters below highlight its capabilities in terms of voltage, current, and thermal efficiency. The thermal resistance is particularly important as it dictates the efficiency of heat transfer away from the semiconductor junction, a critical factor for long-term reliability.

| Parameter | Symbol | Value | Conditions |

|---|---|---|---|

| Collector-Emitter Voltage | Vces | 600 V | Tj = 25 °C |

| DC Collector Current | Ic | 45 A | Tcase = 25 °C |

| Collector-Emitter Saturation Voltage | VCE(sat) | 2.1 V (typ.) | Ic = 45 A, Tj = 25 °C |

| Thermal Resistance, Junction to Case | Rth(j-c) | 0.8 K/W | per IGBT |

| Total Power Dissipation | Ptot | 155 W | Tcase = 25 °C |

| Gate-Emitter Leakage Current | IGES | 200 nA | VGE = ±20 V |

Download the SK45GH063 datasheet for detailed specifications and performance curves.

Technical Deep Dive

A Closer Look at the SEMITOP® 3 Package and Its Impact on Assembly

The defining feature of the SK45GH063 is its integration within the Semikron SEMITOP® 3 package. This package is designed with a single-screw mounting system, which radically simplifies the assembly process. Imagine the production line for a small motor drive: instead of handling and mounting four separate discrete IGBTs, each requiring its own hardware and precise torque application, a technician performs a single, straightforward mounting action. This not only accelerates production but also minimizes the risk of uneven mounting pressure—a common cause of poor thermal contact and eventual component failure. The package's isolated DBC baseplate acts as both an electrical insulator and a thermal conductor, eliminating the need for separate, often fragile, insulating pads. This design choice directly translates to higher manufacturing throughput and enhanced in-field reliability by reducing potential points of mechanical and thermal failure.

Frequently Asked Questions (FAQ)

What is the primary benefit of the Direct Bonded Copper (DBC) substrate used in the SK45GH063?

The DBC substrate provides excellent thermal conductivity combined with high electrical isolation. This allows for efficient heat transfer from the IGBT chips to the heatsink, which is critical for maintaining a low junction temperature and ensuring long-term operational reliability.

How does the integrated H-Bridge configuration of the SK45GH063 simplify circuit design?

By integrating four IGBTs into a single module, the SK45GH063 eliminates the need for complex PCB layouts to connect discrete components. This reduces parasitic inductance and capacitance, potentially improving switching performance and simplifying the overall design of the Gate Drive circuitry.

Is the 2.1V VCE(sat) rating considered efficient for this type of module?

A typical VCE(sat) of 2.1V at its rated current is a balanced value for a 600V non-punch-through (NPT) IGBT. It represents a trade-off between conduction losses and switching losses. This value is suitable for applications where ruggedness and cost-effectiveness are prioritized alongside efficiency.

What does the single-screw mounting system imply for maintenance and field service?

The single-screw design simplifies not only initial assembly but also field replacement. It allows for quicker and easier module swapping, reducing system downtime during maintenance or repair cycles in applications like commercial HVAC systems or automated machinery.

Strategic Implications

Optimizing Assembly Costs in High-Volume Production

For OEMs producing compact motor drives, power supplies, or welding equipment, the SK45GH063 offers a distinct strategic advantage. Its value extends beyond its electrical specifications to the total cost of ownership. The primary lever it pulls is the reduction of assembly complexity and time. In high-volume manufacturing environments, every second saved on the production line translates into significant cost savings. The adoption of a single, integrated module like the SK45GH063 over discrete components streamlines inventory, simplifies procurement, and enhances the reliability of the final assembly, contributing to a more competitive and robust end product.