Content last revised on November 16, 2025

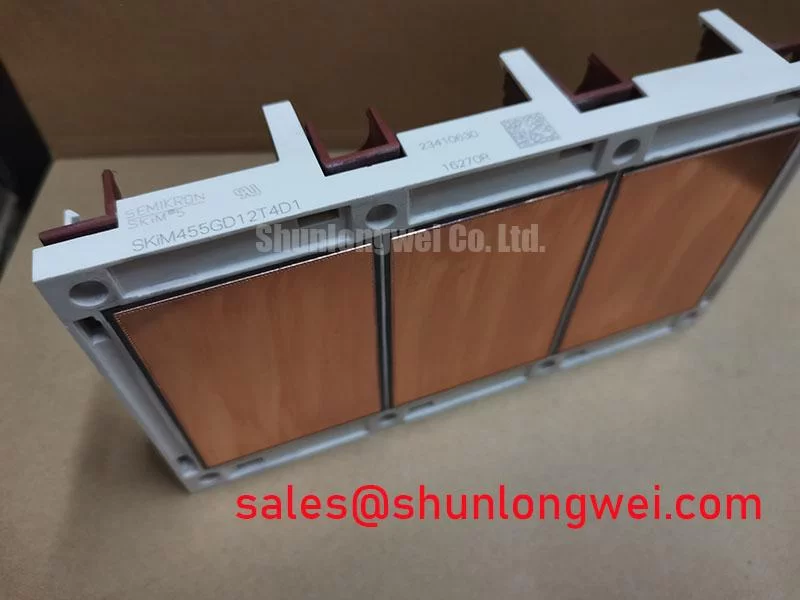

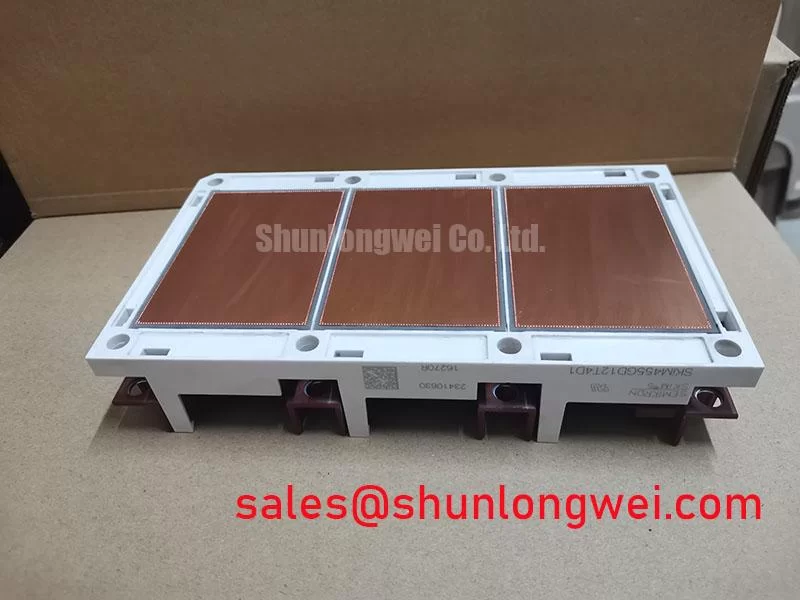

SKIM455GD12T4D1: 1200V 450A Six-Pack IGBT Module for High-Reliability Power Inverters

Engineered for demanding high-power applications, the SKIM455GD12T4D1 from Semikron-Danfoss is a 1200V, 450A six-pack IGBT module that delivers exceptional thermal performance and reliability through advanced packaging. Key Specifications: 1200V | 450A (Nominal) | VCE(sat) 1.70V (typ.). This module offers superior thermal management and simplified system assembly. It directly addresses the challenge of achieving long operational life in high-power density converters by utilizing a solder-free pressure contact system, which mitigates the primary failure mechanism of solder fatigue. For industrial drive systems requiring robust performance under heavy load cycles, the SKIM455GD12T4D1's pressure contact technology offers a decisive reliability advantage.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the SKIM455GD12T4D1 are tailored for performance and longevity in high-stress power conversion systems. The parameters below highlight the module's efficiency and thermal robustness, which are critical for design engineers.

| Parameter | Value | Significance |

|---|---|---|

| Collector-Emitter Voltage (V_CES) | 1200 V | Provides substantial voltage margin for standard 400V/480V AC line applications, ensuring reliability against voltage transients. |

| Nominal Collector Current (I_Cnom) | 450 A | Enables high power throughput, suitable for inverters driving motors in the 150 kW to 250 kW class. |

| Collector-Emitter Saturation Voltage (V_CE(sat)) | 1.70 V (Typ. at I_Cnom, T_j=25°C) | (Highlighted) A low V_CE(sat) directly translates to lower conduction losses, reducing heat generation and improving overall inverter efficiency. |

| Thermal Resistance, Junction to Case (R_th(j-c)) | 0.075 K/W (per IGBT) | (Highlighted) An exceptionally low value indicating highly efficient heat transfer from the IGBT chip to the heatsink, crucial for thermal management. |

| Technology | Trench Field-Stop IGBT4 | A mature and robust technology known for its excellent balance between conduction and switching losses. |

| Internal Configuration | Six-Pack (Three-Phase Bridge) | Integrates a full three-phase inverter stage into a single module, simplifying PCB layout and mechanical assembly. |

Download the SKIM455GD12T4D1 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in High-Power Motor Drives and UPS

The SKIM455GD12T4D1 is engineered to be the core power stage in high-demand systems where both efficiency and long-term reliability are non-negotiable. Its primary applications include industrial Variable Frequency Drives (VFDs), uninterruptible power supplies (UPS), and inverters for renewable energy systems such as commercial solar installations.

High-Fidelity Engineering Scenario: Consider the design of a 200 kW VFD for a critical industrial conveyor system. The key challenge is ensuring uninterrupted operation under fluctuating loads, which causes significant temperature cycling. Traditional soldered modules are susceptible to solder joint fatigue, a leading cause of failure. The SKIM455GD12T4D1's pressure contact technology directly solves this problem. By eliminating solder layers in the thermal path, it provides superior power cycling capability, drastically enhancing the drive's field lifespan. This design choice translates directly to reduced maintenance costs and minimized system downtime, a critical value proposition in industrial automation.

The integrated NTC temperature sensor provides real-time thermal feedback, allowing for precise control and protection within the VFD's control system, ensuring the module operates within its Safe Operating Area (SOA) at all times. This level of integration simplifies the overall system design while enhancing its protective features.

Frequently Asked Questions (FAQ)

What is the primary benefit of the pressure contact technology used in the SKIM455GD12T4D1?

Its main advantage is a dramatic increase in reliability and operational lifetime. By eliminating solder fatigue, which is a common failure point in conventional modules subjected to thermal cycling, it ensures a more robust connection and consistent thermal performance over tens of thousands of load cycles.

How does the low R_th(j-c) of 0.075 K/W impact system design?

This low thermal resistance signifies highly effective heat extraction from the semiconductor chip to the module's baseplate. For a system designer, this means that for a given power loss, the chip's junction temperature will be lower. This allows for either operating at higher currents, simplifying the heatsink design to save cost and space, or building in a greater thermal margin for enhanced system reliability.

Why is Trench Field-Stop IGBT4 technology a suitable choice for motor drive applications?

Trench Field-Stop IGBT4 technology offers a well-optimized trade-off between low on-state voltage (V_CE(sat)) and moderate switching losses. This is ideal for motor drive applications which typically operate at switching frequencies between 2 kHz and 15 kHz. The low V_CE(sat) minimizes heat generation during operation, while the controlled switching characteristics help to manage EMI, a key consideration for compliance with standards like IEC 61800-3.

A Strategic Perspective on Power Module Selection

Selecting the SKIM455GD12T4D1 is a strategic decision that prioritizes long-term system reliability and a lower total cost of ownership over initial component price. The adoption of pressure contact technology is a direct response to the industry's need for power electronics that can withstand the rigorous demands of modern industrial applications. By designing-in this level of reliability at the component level, engineers can develop more compact, efficient, and durable power conversion systems that provide a clear competitive advantage in the market.