Content last revised on January 20, 2026

SKM400GB12E4 IGBT Module: Data for Power Converters

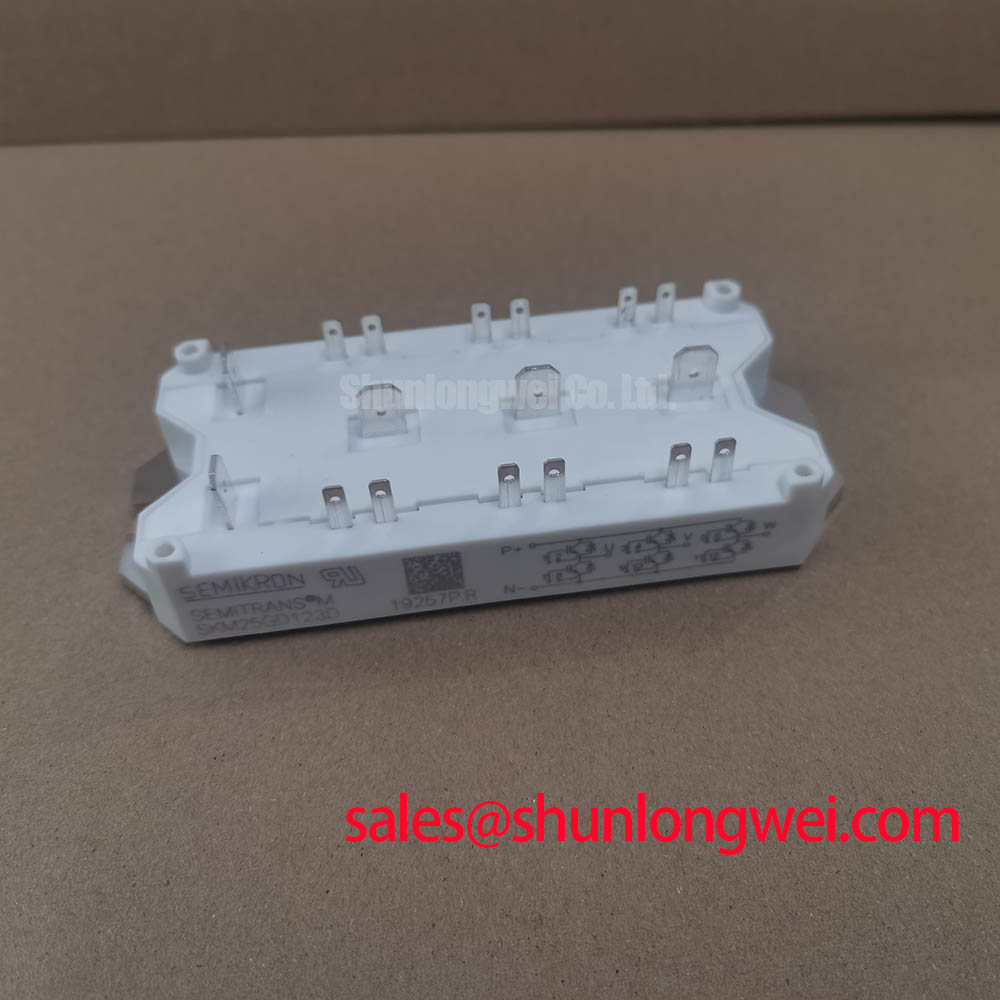

Technical Overview of the SEMITRANS 2 IGBT Module

The Semikron-Danfoss SKM400GB12E4 is a high-efficiency half-bridge IGBT module engineered to reduce total power losses in demanding inverter and power conversion systems. Its design centers on a strategic balance between conduction and switching performance. How does the SKM400GB12E4 minimize power losses in high-frequency applications? It achieves this through the integration of 4th generation trench gate IGBT technology with a soft-switching CAL4 freewheeling diode, effectively managing both on-state and transitional energy dissipation.

- Core Specifications: 1200V | 400A | VCE(sat) (typ.) 1.7V

- Key Benefits: Reduced total switching losses; Enhanced EMI performance.

Powering High-Frequency Industrial Systems

The technical characteristics of the SKM400GB12E4 are tailored for applications where switching efficiency directly impacts system performance, thermal management, and operational costs. The module's internal configuration and component technologies make it a strong candidate for a range of power conversion tasks that demand robust and reliable power handling.

- Variable Frequency Drives (VFDs): The module's ability to balance low VCE(sat) with controlled switching losses is critical for motor drives, where efficiency across a wide range of operating speeds and loads is essential.

- Solar Inverters: In grid-tied solar applications, maximizing energy conversion efficiency is paramount. The low conduction losses of the SKM400GB12E4 contribute to higher energy yield.

- Uninterruptible Power Supplies (UPS): The module's robust design and reliable switching characteristics provide the stability needed for critical power backup systems, ensuring minimal energy loss during operation.

- Welding Systems: High-frequency welding power supplies benefit from the fast and soft switching behavior of the integrated CAL4 diodes, enabling precise control and reducing electromagnetic interference.

What is the primary benefit of its CAL4 diode technology? It provides soft reverse-recovery characteristics, which minimizes voltage overshoots and electromagnetic emissions. For motor drives operating at moderate switching frequencies where minimizing conduction losses is a priority, the SKM400GB12E4's 1.7V typical VCE(sat) offers a thermally efficient design foundation.

Decoding the IGBT4 and CAL4 Diode Synergy

The performance of the SKM400GB12E4 is fundamentally rooted in its two core semiconductor technologies: the Trench Field Stop IGBT 4 (IGBT4) and the CAL4 (Controlled Axial Lifetime) freewheeling diode. Understanding their interplay is key to leveraging the module's full potential.

The IGBT4 chip represents a mature and optimized technology that provides a well-balanced performance profile. It is engineered to achieve a low collector-emitter saturation voltage (VCE(sat)), which directly translates to lower conduction losses when the switch is active. This is analogous to reducing resistance in a simple circuit; less voltage drop across the device at a given current means less power is wasted as heat. This focus on reducing on-state losses is particularly beneficial in applications with high duty cycles.

Complementing the IGBT is the CAL4 freewheeling diode. During the IGBT's turn-off phase, the diode must take over the load current. A standard diode can exhibit abrupt "snappy" recovery, causing high voltage spikes and EMI. The CAL4 diode is designed for "soft" recovery. This controlled, smoother transition mitigates voltage overshoots and ringing, simplifying the requirements for external snubber circuits and easing EMI compliance efforts for the overall system design.

Data-Informed Selection: SKM400GB12E4 Parameter Focus

For engineers evaluating power modules, direct parameter comparison provides essential data for simulation and design validation. The following table places the SKM400GB12E4 alongside a component from a different series to highlight key performance metrics. This data is presented to support your technical assessment.

| Parameter | SKM400GB12E4 | SKM400GB12T4 | Engineering Implication |

|---|---|---|---|

| Technology | IGBT4 + CAL4 Diode | Trench Gate IGBT4 | The CAL4 diode in the SKM400GB12E4 is specifically optimized for soft switching, potentially reducing system-level EMI. |

| VCE(sat) (Typ. @ 400A, 125°C) | 1.7V | 2.15V | A lower VCE(sat) indicates lower on-state power loss, leading to higher efficiency and reduced heat generation. |

| Eoff (Typ. @ 400A, 125°C) | 27 mJ | 23 mJ | A slightly lower turn-off energy suggests the SKM400GB12T4 may have an advantage in very high-frequency switching scenarios, illustrating a classic efficiency trade-off. |

| Rth(j-c) per IGBT | 0.06 K/W | 0.06 K/W | Identical junction-to-case thermal resistance indicates comparable heat transfer efficiency from the silicon chip to the module baseplate. For more information on this critical parameter, see our guide on unlocking IGBT thermal performance. |

Note: The data presented is based on respective product datasheets. Design decisions should be based on a comprehensive analysis of all relevant parameters under specific application conditions.

Engineering Specifications for Efficient Power Conversion

The following parameters from the official datasheet are critical for system design, simulation, and thermal modeling. Each specification provides insight into the module's operational limits and efficiency characteristics.

| Parameter | Value | Engineering Significance |

|---|---|---|

| Collector-Emitter Voltage (Vces) | 1200 V | Defines the maximum blocking voltage capability, providing the necessary margin for applications running on DC bus voltages up to approximately 800V. |

| Continuous DC Collector Current (Ic @ Tc=80°C) | 400 A | Specifies the maximum continuous current the module can handle at a defined case temperature, a primary factor in determining power throughput. |

| Collector-Emitter Saturation Voltage (VCE(sat) @ Ic=400A, Tvj=125°C) | 1.7 V (typ.), 2.1 V (max.) | This value is the cornerstone of conduction loss calculation (Ploss = VCE(sat) * Ic). A lower value directly correlates to higher energy efficiency and less heat to dissipate. |

| Total Switching Energy (Ets @ Ic=400A, Tvj=125°C) | 47 mJ (typ.) | Represents the combined energy lost during turn-on and turn-off events. This parameter is crucial for calculating switching losses, which become dominant at higher frequencies. |

| Thermal Resistance, Junction to Case (Rth(j-c)) | 0.060 K/W per IGBT | Indicates the efficiency of heat transfer from the semiconductor junction to the module's baseplate. A lower thermal resistance simplifies heatsink design and helps maintain lower operating temperatures. |

| Short Circuit Withstand Time (tsc) | 10 µs | A critical safety parameter defining how long the IGBT can survive a direct short-circuit condition before catastrophic failure, allowing time for protection circuits to react. For a deeper understanding of failure modes, explore our analysis of IGBT failure analysis. |

Download the Datasheet for complete specifications and performance graphs.

Strategic Advantages in Energy-Conscious Designs

The adoption of components like the SKM400GB12E4 aligns with broader industry trends towards greater energy efficiency and power density. As regulations governing energy consumption (e.g., EU Ecodesign Directive) become more stringent, the need for power stages with minimal losses becomes a strategic imperative. The module's use of Semikron-Danfoss's established IGBT4 technology provides a pathway to meeting these targets without resorting to more complex and costly wide-bandgap materials in applications where they may not be required. Furthermore, the robust, industry-standard SEMITRANS 2 package simplifies both new designs and retrofits, offering a proven mechanical and thermal interface that accelerates development cycles and enhances field reliability.

Technical Inquiries on the SKM400GB12E4

1. What is the main advantage of the IGBT4 technology used in the SKM400GB12E4 compared to older generations?

IGBT4 technology provides a superior trade-off between conduction losses (VCE(sat)) and switching losses (Eon/Eoff). Compared to earlier non-punch-through (NPT) or field-stop (FS) generations, it allows for a lower VCE(sat) for a given switching speed, leading to higher overall efficiency in many mainstream inverter applications.

2. How does the CAL4 diode's "soft recovery" impact the gate drive design?

The soft recovery reduces the rate of current change (di/dt) during reverse recovery, which in turn minimizes induced voltage overshoots on the DC bus. This can relax the requirements for the gate drive's Miller clamp functionality and may allow for simpler, lower-cost gate driver solutions, as the device is inherently less prone to parasitic turn-on.

3. Is paralleling multiple SKM400GB12E4 modules recommended for higher current output?

Yes, paralleling is a common practice. The positive temperature coefficient of the VCE(sat) in IGBT4 technology provides a degree of self-balancing for static current sharing. However, for effective dynamic current sharing during switching, careful attention must be paid to the symmetry of the gate drive layout and the busbar inductance to ensure balanced performance.

4. What is the typical maximum switching frequency for this module?

While the datasheet does not specify a maximum frequency, it is application-dependent and limited by thermal performance. The typical total switching energy of 47 mJ at nominal current implies that as frequency increases, switching losses (Psw = Ets * f_sw) will become the dominant source of heat. Most applications for a module of this size and technology operate in the range of 2 kHz to 20 kHz.

5. Does the insulated copper baseplate affect thermal performance compared to a non-insulated one?

The primary purpose of the insulated baseplate is to provide electrical isolation (2500V AC for 1 minute). While any insulation layer adds some thermal resistance, the use of materials like Aluminum Nitride (AlN) in the Direct Bonded Copper (DBC) substrate is engineered to minimize this impact, providing excellent thermal conductivity while ensuring high dielectric strength.

Field Application Snapshot

In a mid-power industrial motor drive (approx. 150-200 kW), a design team was tasked with improving the overall efficiency of the inverter stage to meet new energy standards. By replacing an older generation IGBT module with the SKM400GB12E4, they were able to observe a measurable reduction in total losses, primarily due to the lower VCE(sat). This thermal improvement allowed them to maintain their existing heatsink design, avoiding a costly mechanical redesign of the entire cabinet. The soft recovery of the CAL4 diode also resulted in a cleaner switching waveform, reducing the budget and board space allocated to EMI filtering components.

A Designer's Perspective on Future Optimization

From a system design standpoint, the SKM400GB12E4 represents a highly optimized silicon-based solution. For engineers seeking to further push the boundaries of power density and efficiency, the next logical step involves evaluating the thermal interface. Optimizing the connection between the module's baseplate and the heatsink using high-performance thermal interface materials (TIMs) can yield significant improvements in junction temperatures. Additionally, implementing a more sophisticated gate drive with adjustable turn-on/turn-off speeds can allow designers to fine-tune the balance between switching losses and EMI performance on a per-application basis, extracting the maximum capability from this robust power module.